Underground car parks. Part 2 | Life Cycle Assessment

Detailed Design | The Netherlands

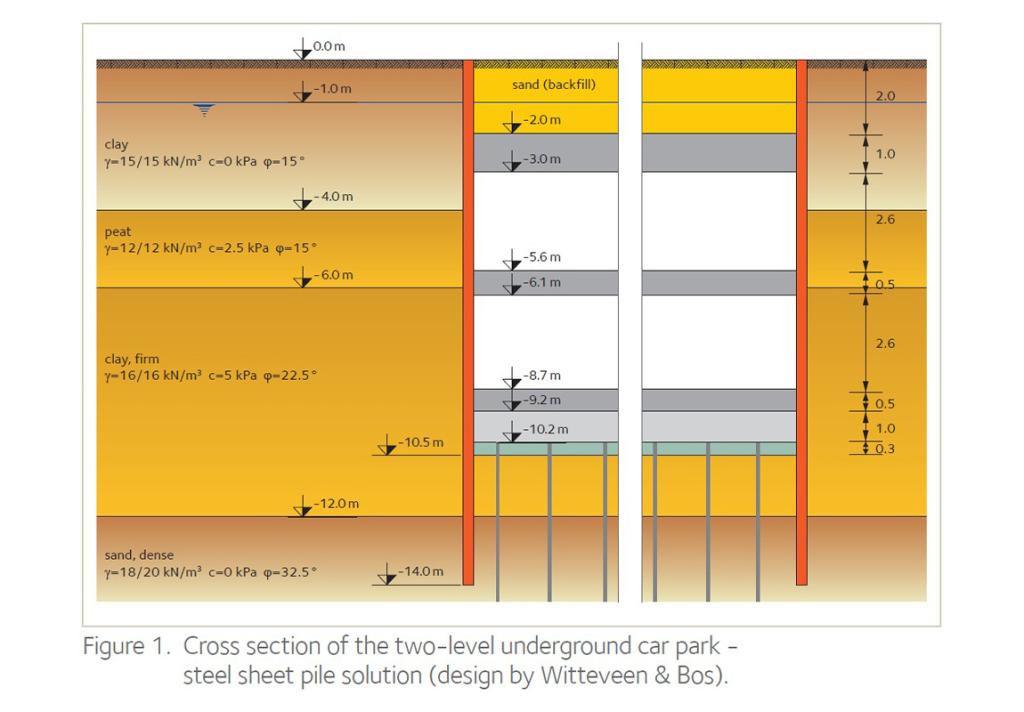

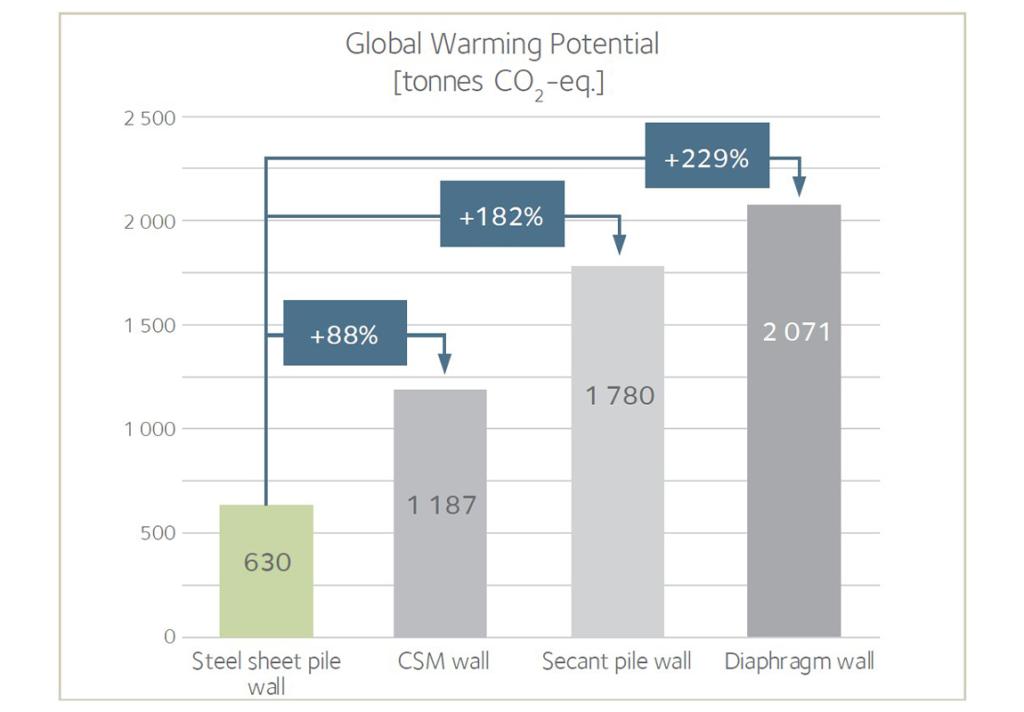

The technical and economic analysis of this case study was performed by the Dutch consulting engineers Witteveen & Bos for ArcelorMittal in 2020. The design assumptions were determined for a two level below grade underground car park in soil conditions that are typical for the region of Amsterdam in the Netherlands. The design assumptions were the same for the four alternatives. From an engineering point of view, such simplified assumptions for a soil can be used for a feasibility study or for a comparison of different alternatives.

ArcelorMittal emphasizes on the fact that Witteveen & Bos performed an objective and unbiased case study. The analysis is a purely hypothetical case study with its limitations on reliability on costs and techniques, since these aspects can be very dynamic in markets and different subsoils.

Download

English

English