Mobility Infrastucture Solutions

Underground construction

355 tonnes of sheet piles

Underground Car Park in Brasil | 2016

Being a relatively recent development, the architecture consists primarily of small buildings and residences close to the seafront, with up to three stories. However, like in most urban cities, parking area is a challenge for new residential buildings and shopping malls.

Download the full case study

The choice of the two-level underground car park for the new shopping mall and hotel Vogue Square was quite straightforward, and the design engineer proposed to the owner a still quite rare solution in Brazil: steel sheet piles used as the permanent retaining wall around the parking, but foremost, the sheet piles stay apparent. To enhance aesthetics, sheet piles are coated.

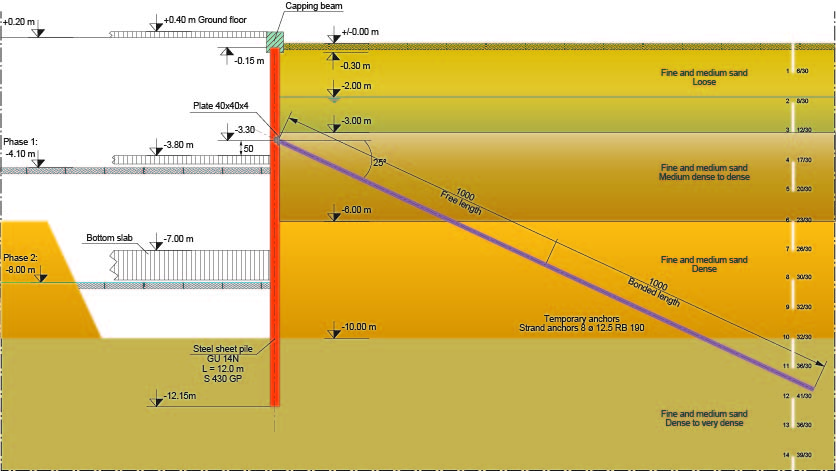

ArcelorMittal supplied 355 tonnes of 12.0 m long GU 14N sheet piles in steel grade S 430 GP. According to European standards (EN 1993- 5), retaining walls built with U-type sheet piles should be installed as double piles, and each double pile should transfer shear forces, so the double piles were delivered crimped (standard pattern).

The ground consists of loose fine sands in the upper layer, and medium to dense sand deeper layers, with SPT values ranging from 6 at the top up to 41 at the tip of the sheet pile.

During the temporary excavation phase, the sheet pile wall was anchored with one row of grouted anchors at elevation -3.30 m. The pre-stressed strand anchors were 8 ø 12.5 RB 190, 20 m long, with a minimum resistance of 736 kN working load. During the service life, the anchors are released and the concrete slabs act as permanent struts. The top slab is 30 cm thick, the second slab is 40 cm thick, and the 100 cm thick bottom slab of the parking was designed as a raft foundation to resist the hydrostatic pressure due to groundwater (Archimede’s principle, around 6 m of water pressure difference).

The design life of 50 years can be achieved by combining a coating protection with an estimated loss of steel thickness of 1.0 mm on the bare steel surface in the atmospheric zone. The coating system is a 180 m thick epoxy layer on a zinc primer, applied only on the excavation side, over 60% of the sheet pile length.

The project started in 2014, and the sheet piles were supplied and installed between August and September of 2014. The key advantage of the steel sheet pile solution was definitely its fast execution. It took the contractor only 35 days to install the 230 double piles, with a daily average rate of 6 to 7 double piles. ThyssenKrupp Brazil drove the sheet piles using a vibratory hammer ABI MRZV 30VV with a centrifugal force of 1 500 kN, and a variable static moment of 30 kgm, mounted on an excavator ABI MOBILRAM TM 20/25 SD.

It is worthwhile to note that the sheet piles were driven close to an existing building without affecting its operations nor its foundations.

The groundwater was lowered during the various execution phases by using wells inside the excavation.

Additional key advantages of the sheet pile solution were the high watertightness of the wall, the great, yet uncommon aesthetical aspect, the reduced number of workers required to execute the retaining wall, and the fact that being a prefabricated element, there is no need for curing time or inspection of the quality of in-situ poured material. Besides, such a work environment is quite clean for a construction site.

A concrete capping beam on the head of the sheet piles allows for an impeccable finish, and for transmission of vertical loads from the superstructure to the soil.

The mall and the hotel opened in 2016.