Benefits of steel solutions in bridge design

Today’s modern bridge construction projects face new challenges. The public, the regulators and the authorities demand new structures that are cost effective during their planning, execution, lifetime and dismantling. This translates into a higher relevance of the life cycle costs, and the so-called external costs associated with the execution and maintenance of the structure.

Our contribution to pioneering projects

Politicians, building regulators and other decision makers face the challenge of choosing sustainable bridge designs, for which the price of the construction is not the only variable, but one of many, such as construction time, social impact (during construction and operation), environmental impact, maintenance, etc. Current procurement practices tend to favour the cheapest bridge design with low construction cost, disregarding expenses due to operation and maintenance and ignoring the impact that longer construction times have on traffic conditions and the public.

Approximately 80 % of the bridges that comprise the European road network can be classified as small or medium span structures of less than 50 m. When performing a very simple analysis, reinforced concrete and prestressed concrete appear to be the most cost-efficient solutions available. On the other hand, it is widely accepted among the construction industry that composite structures are the best solution, either for spans larger than 50 m, or when height restrictions apply, or if shorter construction periods are required. In recent years, numerous studies and examples have demonstrated that composite bridges provide cost effective solutions for shorter span structures even if these conditions do not apply.

Bridge Abutment Factbook

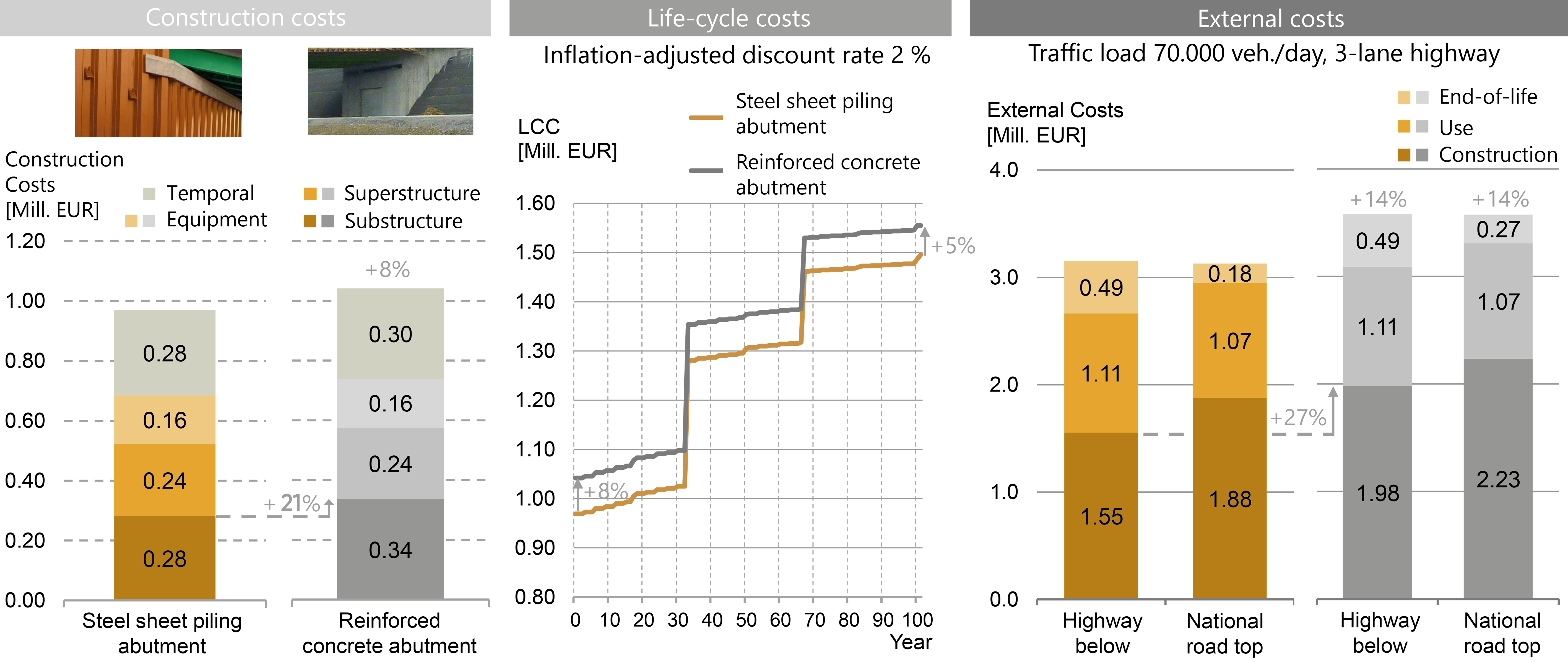

Steel sheet pile bridge abutments offer significant benefits. A comparative study undertaken by the Karlsruhe Institute of Technology (KIT) in 2018 underscored the advantages of bridges designed with sheet pile abutments.

The right choice of bridge design

For two-span road bridges with an average span and traditional abutments, the construction of the abutment accounts for approximately 40 % of total manufacturing costs of the bridge if no temporary pit walls are required. This figure rises up to roughly 55 % when temporary retaining walls are required for the construction. In these situations, abutments with sheet piles are a smart alternative to traditional construction, as the sheet pile can take over both functions, serve as retaining walls and as permanent, load-bearing structural elements.

Steel sheet piles are always highly cost-effective whenever the construction of the structure requires additional temporary pit walls. This is the case, when a change of ground level is to be accommodated during the construction stage, when building below the groundwater table and when the excavation pit needs to be protected against flooding.

Further the use of steel sheet pile abutments instead of abutments with temporary buildings pit walls can reduce total construction time by a minimum of 10 %.

There are also significant advantages when building the composite bridge deck on hot-rolled, high strength steel sections. To reduce the space needed for the construction site, these composite elements can be partially prefabricated offsite and supplied to the construction site as load bearing elements during construction and the final stages. In addition, it is possible to install the prefabricated bridge girders during brief shut down periods of the crossed road, avoiding major disturbances to drivers and commuters, allowing traffic to circulate below the bridge while any subsequent work is safely carried out above the carriageway.

The hidden costs of traffic congestion

Not only the direct building costs must be considered, but also the economic costs generated by delays, increased fuel consumption and air pollution caused by traffic congestion during the bridges’ life cycles. Congestion has a massive economic impact.

According to data published in 2016, the average cost per hour that a European passenger spends stuck in traffic is estimated at 20€. The hidden costs of traffic congestion.

Choosing a design with a reduced construction time, and with low maintenance requirements, becomes a priority when a global analysis takes the cost of the external effects into account. Especially as one of the main reasons for slow moving traffic the construction sites are going to grow in number in the coming years, as the infrastructure investment in Europe is foreseen to increase.

The study

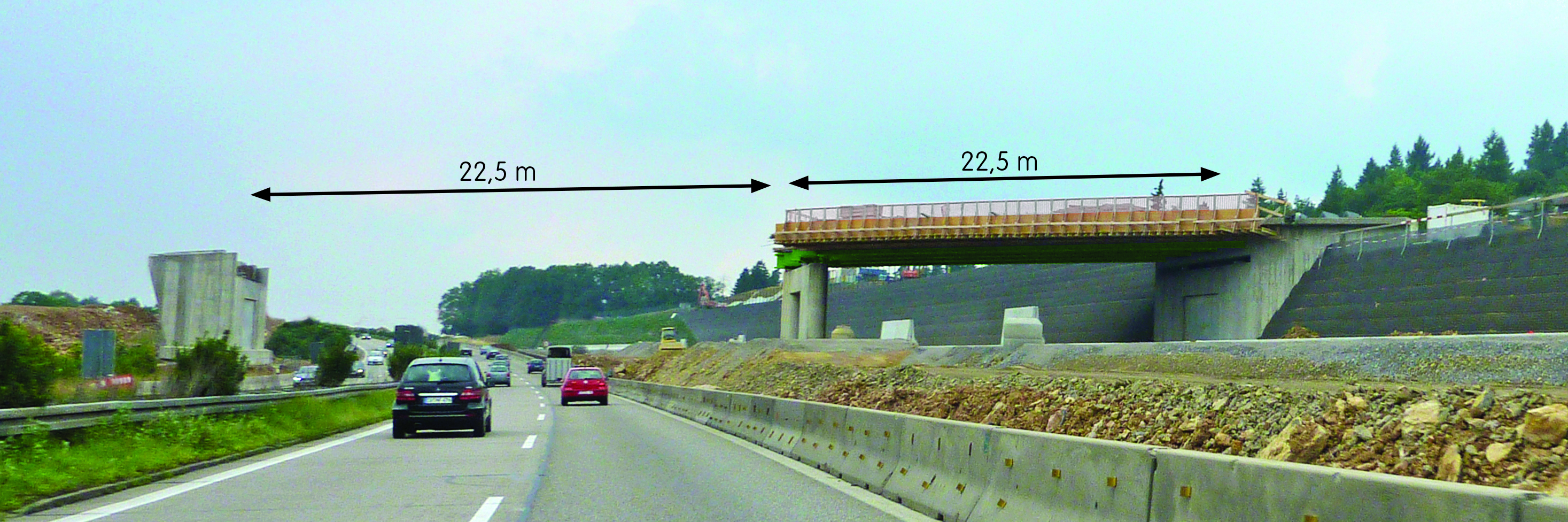

A case study, performed by the Karlsruhe Institute of Technology (KIT), assesses all associated costs and performance of a traditional concrete bridge versus a bridge whose abutments are constructed using steel sheet pile sections. This comparison is performed for a two-span superstructure with spans of 22,50 m and a superstructure width of 11,50 m accounting for a standard crossing of a national road over a 3-lane motorway with an average daily traffic (ADT) of 70 000 vehicles.

Option 1: Steel Sheet Pile abutment (SSP abutment)

• 16 m long piles on the front wall.

• 13 m long piles on the lateral wings.

Option 2: Reinforced concrete abutment (RC abutment)

• 4 piles per abutment plus 2 per wing wall.

• 10 m length concrete piles of 90 cm diameter.

Choosing a bridge designed with steel sheet pile abutments and a composite deck built with steel sections leads to global cost benefits such as:

- 8 % reduction on the construction costs;

- A residual 5 % advantage in life cycle costs over 100-year period (based on a real discount rate of 2 %);

- A potential reduction of up to 18.5% in the economic impact of external effects during the structure's service life

- A confirmed reduction of at least 10% in total construction time for bridges utilizing sheet pile abutments compared to those with temporary shoring.

- The environmental impact of the steel sheet pile abutment over the life cycle of the bridge is 36 % lower than for the RC abutment, leading to 12 % lower emissions for the overall bridge structure.

Bridge-building technologies of the future: fast, efficient and economical in the long term

Composite steel bridges with steel sheet pile abutments are robust structures that require limited maintenance and repairs. Due to the use of state of the art corrosion protection techniques 100-years design life without the need to replace any component are achieved.

Steel sections offer the advantage of an easy dismantling, recovery and recycling after the bridge service life, ensuring that no residues remain in the soil and adding a valuable contribution to the circular economy. This helps to prevent the abuse of natural resources.

References

- Friedrich H.: Aktuelle Herausforderungen und zukünftige Entwicklungen im Brückenbau im Bundesfernstraßennetz (Current challenges and future developments for bridge constructions in the federal highway network). Stahlbau 87 (2018), issue 6.

- Schmitt V., Seidl G., Vogel C.: Untersuchungen zum verstärkten Einsatz von Stahlverbundkonstruktionen bei Brücken kleiner und mittlerer Stützweiten (Investigations on the increased use of steel composite structures for bridges with small and medium spans). P629 Forschungsvereinigung Stahlanwendungen e.V., final report, 2006.

- Grundbau-Taschenbuch. 8th edition, Ernst & Sohn, 2018.

- RI-WI-BRÜ – Richtlinie zur Durchführung von Wirtschaftlichkeitsuntersuchungen im Rahmen von Instandsetzungs-/ Erneuerungsmaßnahmen bei Straßenbrücken, BMVBS, 2007.

- Zinke T.: Neue Brücken braucht das Land. Frankfurter Allgemeine Zeitung Verlagsspezial / Zukunft Stahl / 30 November 2017.

- Zinke T.: Nachhaltigkeit von Infrastrukturbauwerken – Ganzheitliche Bewertung von Autobahnbrücken unter besonderer Berücksichtigung externer Effekte (Sustainability of infrastructure structures – Holistic assessment of motorway bridges with special consideration of external effects). Karlsruhe: KIT Scientific Publishing, Dissertation 2016.