Jagged walls

AZ & U jagged walls

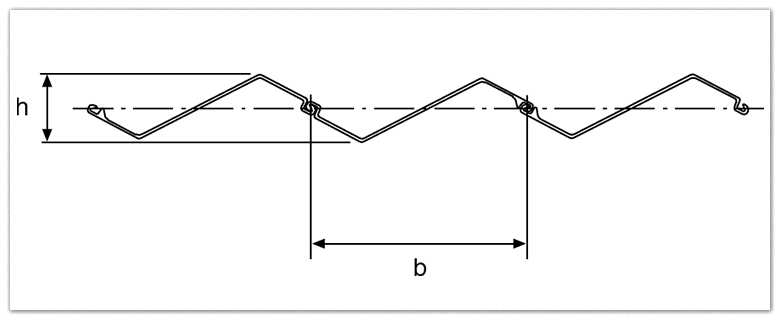

Jagged walls are special arrangement of Z-type or U-type sheet piles for specific applications: sealing screens (AZ) or high inertia and high modulus walls (U).

Installation of Z-type jagged walls in compact soils needs special care.

AZ jagged walls

AZ® sections threaded in reverse form special arrangements that can be used in applications that require only small section modulus and moment of inertia, but which for instance need a minimum thickness or a higher watertightness.

- Jagged walls - AZ

- Jagged walls - AZ-800

- Jagged walls - AZ-770

- Jagged walls - AZ-750

- Jagged walls - AZ-700

The AZ jagged wall represents a very economical solution for sealing screens: reduced height of the wall, constant thickness (for the lighter AZ sections), low driving resistance (no plugging at the toe), better watertightness due to less interlocks per running meter of wall (the imperviousness of the wall can be improved with sealing systems),….

Note that due to the low stiffness of the elements, the length of the sheet piles used in such an arrangement is in most soil conditions rather limited.

Typical applications are river and bank reinforcement, shallow trenches, containment barriers,….

Technical database

Consult our products characteristics

U jagged walls

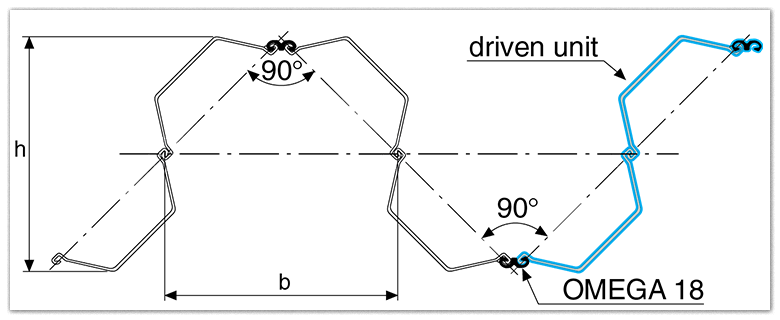

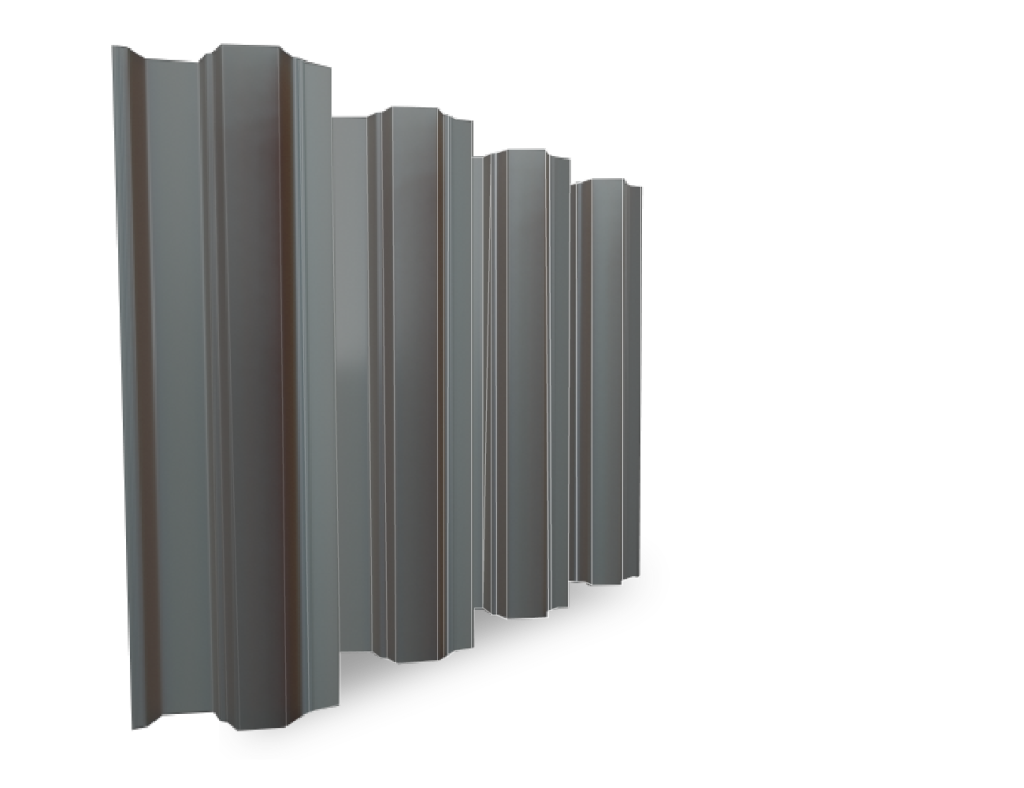

A specific arrangement of U-type steel sheet piles forms a jagged wall. It offers an alternative to a combined wall system where high moment of inertia and section modulus are required.

The geometrical values shown in the table assume an efficient solidarisation of each driving element, i.e. crimping or (partial) welding of the common interlock of a double pile. The OMEGA 18 corner section is threaded and welded at the mill, either by tack welding, in which case it does not contribute to the section properties of the jagged wall, or by an appropriately designed weld, so that it fully contributes to the section properties.

Note that for supported walls, either with an anchorage or with a strut system, an adequately designed stiffening system (plates, concrete capping beam,...) must be provided at the support levels.

Due to the geometry of the wall, a special guiding frame, which shall be stiff enough, is required for the installation.

Our projects

Learn more from real practical cases