Circular Economy

Reduce Reuse Recycle

Steel is a permanent material: never consumed, but continuously transformed; the use of natural resources for producing steel the first time is therefore a transformative process, making iron available in a more “practical form” for subsequent uses (life cycles), and thereby reducing the medium/long term pressure on natural resources.

Circular economy has the objective to reduce the creation of waste systematically throughout the different life cycles of a product. This is in contrast to linear take-make-dispose economy, which wastes large amounts of embedded materials, energy and labour.

ArcelorMittal's Sheet Piling is a major actor in the circular economy, aiming for better productivity and reduction of waste. Steel sheet piles can be reused several times in temporary applications, thus reducing the environmental impact each time the sheets are re-used. At the end of life, when they cannot be reused, 100% of the steel can be recycled.

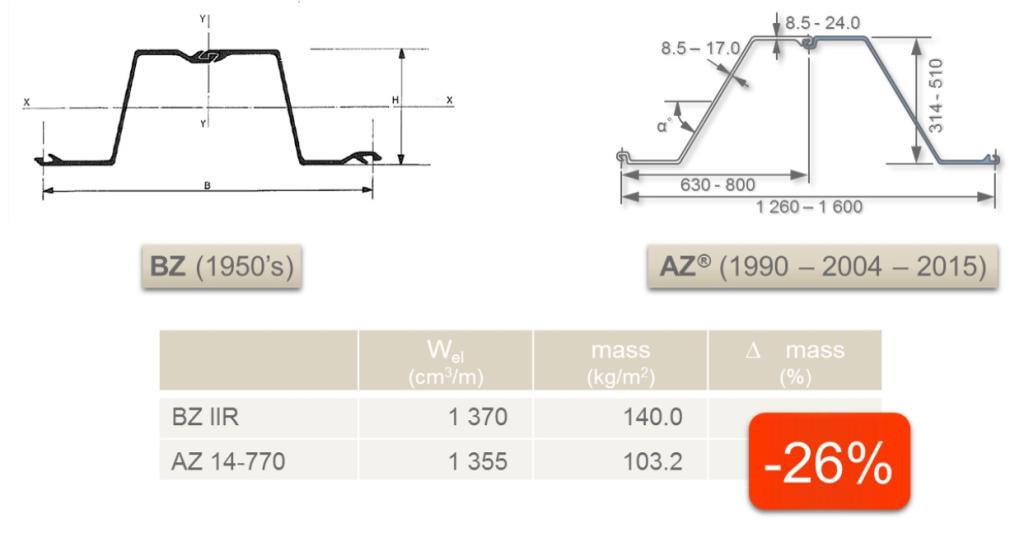

Reduce

Reducing the consumption of raw materials is one way to protect the environment. This precept is fundamental to the steel industry which strives for lighter, but stronger sections. As an example, consider a sheet pile section from the 1950's and compare it to a brand new one from 2015. For the same section properties (elastic section modulus), the new AZ 14‑770 is 26% lighter than the equivalent BZ IIR! These are significant savings.

Now, let's dive a little bit deeper into the design of steel sheet piles. The key parameters for the choice of a section are the section modulus W (elastic or plastic) and the yield strength fy. In the allowable stress design method, the formula is quite simple:

M = Wel * fy

with :

M = bending moment,

Wel = elastic section modulus

fy = yield strength

Hence, if you increase the yield strength, you can reduce the required elastic section modulus proportionally.

In the 1950's, a steel grade S 355, with a yield strength of 355 MPa, was much more expensive than the standard S 235, with fy = 235 MPa. Today, steel sheet piles can be delivered with a yield strength up to 500 MPa. Higher steel grades are slightly more expensive than a standard S 355 GP, but the cost difference is by far offset by the savings that can be made on the weight of the sheet pile section.

Rule: higher steel grades usually allow the selection of a lighter pile, thus reducing the environmental impact of a steel solution.

Additionally, the European design code EN 1993-5 allows even to consider the plastic section modulus Wpl for class 2 sections, which means an additional increase of the resistance of a section between 10% and 25%!

Conclusion: innovation in steel and rolling technology, as well as installation equipment, made it possible to reduce the quantity of steel required to execute exactly the same retaining wall by more than 50% in a few decades. Besides, the solutions are cheaper than ever. And this trend will continue at the same pace.

Reuse

Steel sheet piles can be used and reused several times for temporary applications, thus reducing the environmental impact each time the sheets are re-used. At the end of life, when they cannot be reused anymore, 100% of the steel can be recycled.

Additionally to the traditional sales, two business models catalyze the contribution of sheet piles to circular economy:

- short / medium term rental (by manufacturer or trader): contractors can rent the sections they need for each specific project, thus optimizing the use of the steel as well as their required investment,

- sales and buy-back: after the end of the execution of a project (temporary application of sheet piles), the contractor can either choose to keep the sheet piles, for instance if he has another project where he can use the same sections (or if he found a buyer for the second-hand sheet piles), or to return them back to the manufacturer at a price negotiated before the sales (provided the piles are in a good shape).

Recycle

Steel is a permanent material: never consumed, but continuously transformed. The use of natural resources for producing steel the first time is therefore a transformative process, making iron available in a more “practical form” for subsequent uses (life cycles). Steel is actually a resource that can be re-used several times and recycled indefinitely.

Unlike other materials used in retaining walls and deep foundations, steel sheet piles can be extracted from the ground at the end of the service life of the structure, and recycled at 100%. Even after its service life steel has an inherent value because it can be recycled in an electric arc furnace (for instance) to produce again and again steel products with the same or even better quality.