Technical aspects

Enhancing infrastructure: key aspects of steel sheet pile performance

Specific technical aspects such as durability, imperviousness of steel sheet pile walls, seismic design, etc. may need to be dealt with. Below are the most common issues and their solutions.

Sustainability is handled more in depth in dedicated section of the website.

Durability

Steel sheet piles are widely used in permanent earth retaining and structural foundation works. In the majority of circumstances, they can be used in an unprotected condition. The degree of corrosion and whether protection is required depends upon the working environment - which can vary even within the same installation.

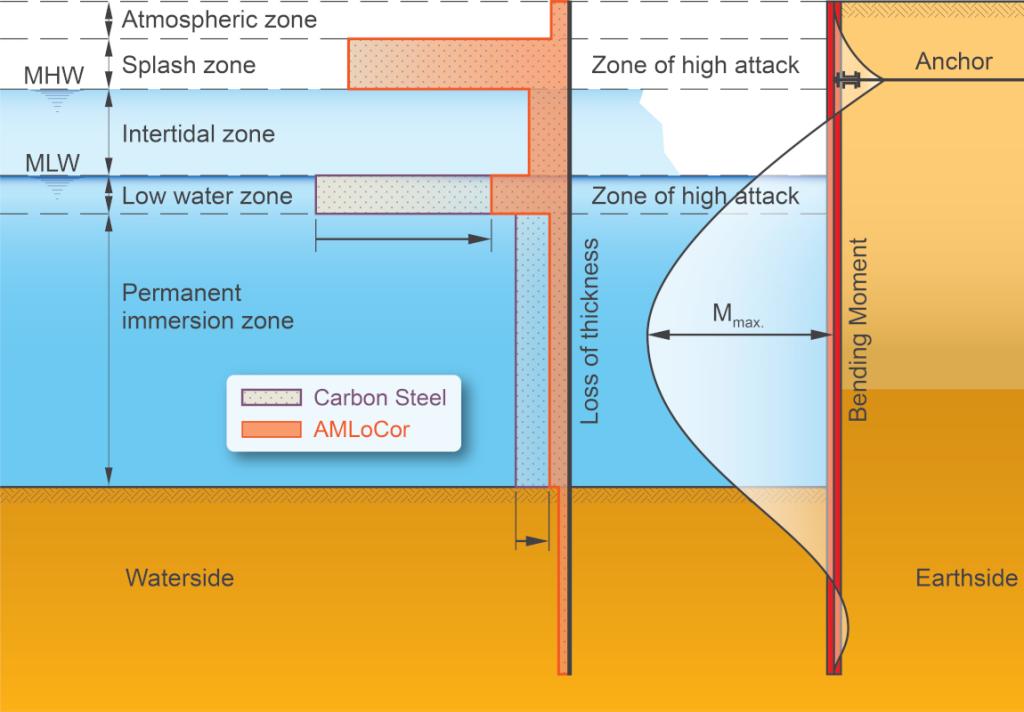

In general, marine environments are the most corrosive and unpredictable. In the few metres of vertical zoning which most structures encompass, parts of the sheet piles are in contact with soil, and exposed to seawater immersion, inter-tidal, splash and marine atmospheric environments.

For most environments, characteristic corrosion rates have been measured (soil, atmospheric, fresh water, marine environment…). The ideal case is to consider corrosion rates measured in adjacent structures, but most often, these data are either not available or not reliable. Typical corrosion rates can be taken from the European standard EN 1993 – Part 5. Note that in specific situations, corrosion due to local conditions may lead to higher corrosion rates, requiring detailed site examinations and data analysis.

In many circumstances steel corrosion rates are low and the use of protective methods is not necessary. However, there are circumstances where corrosion can be more significant, so that measures capable of increasing the service life of a structure should be considered.

Protection measures and design considerations include one or a combination of following methods:

- coatings (typically only in zones with high corrosion probability);

- use of a stronger / thicker section, or a higher steel grade, to create a "statical reserve";

- design to avoid the maximum bending moments in zones with high corrosion rates;

- extension of the concrete capping beam below the low-water level;

- use of AMLoCor® steel grade (most efficient in the permanent immersion zone and low water zone);

- use of Mariner steel grade ASTM A690 (splash zone);

- cathodic protection by impressed current or by sacrificial anodes (protects the surface constantly in contact with water).

The adverse effects of abrasion and erosion should be taken into account in the design or in the selection of protective methods, e.g. the use of a special coating.

Finally, pitting corrosion, a local phenomenon usually limited to a small portion of the surface of the structure, should be monitored. Measures to prevent retained soil form being washed out through the small holes are easy to implement. Note that generally speaking, pitting corrosion does not affect the overall stability of the retaining wall.

In most cases, the design with a sacrificial thickness of steel is the most cost-effective.

In harsh maritime environments, for the portion below water, cathodic protection can be designed right from the beginning and installed later if monitoring of the structure shows that the corrosion rates after several years are higher than foreseen in the design assumptions.

AMLoCor® - steel grade for maritime structures

AMLoCor leads to considerable savings in steel weight compared to the unprotected carbon steel piling solution, as soon as the predicted loss of steel thickness in the immersion zone is significant (higher than in EC 3‑5). Cathodic protection or coatings can be used to increase the service life of the sheet pile structure, but AMLoCor will in many cases yield the most cost-effective solution in the long-term when including maintenance and repair costs.

Note that it is compatible with cathodic protection and coatings.

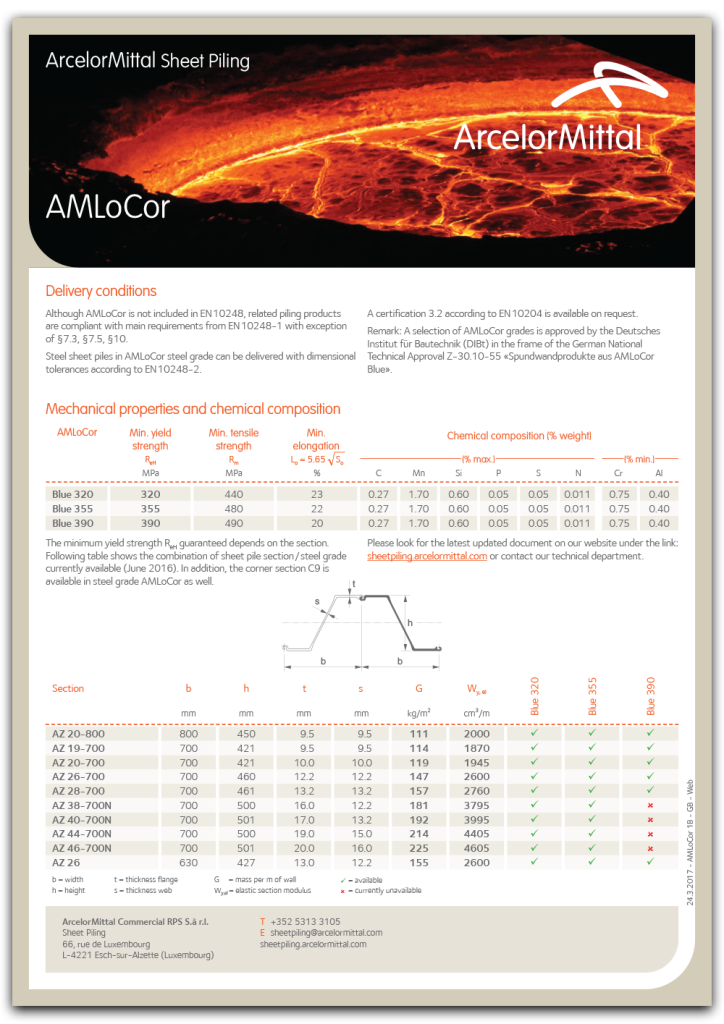

AMLoCor steel grades are covered by the German National Technical Approval Z‑30.10‑55 of the DIBt (Deutsches Institut für Bautechnik) issued in 2017, and a patent is pending.

Their mechanical properties are fully equivalent to standard piling grades, so that structural resistance can be determined according to all relevant design codes used for steel sheet piling structures, for instance EC 3‑5 in European countries.

Some AZ sections are available in AMLoCor, ranging from AMLoCor Blue 320 to Blue 390 (yield strength of 320 MPa up to 390 MPa).

An extensive driving test was performed in 2010 in Denmark. The same sheet pile profiles in S 355 GP and AMLoCor Blue 355 were driven into very hard soils containing some boulders. The piles were monitored during driving, then pulled out and inspected. The test proved that the behaviour of AMLoCor sheet piles is equivalent to regular carbon steel sheet piles.

Watertightness of sheet piles

Steel sheet piles are completely impervious. The only possibility of water infiltrating through a sheet pile wall is by penetration through the interlock. Due to its shape, the Larssen interlock naturally provides high seepage resistance. Sealing systems are therefore not necessary for applications such as temporary retaining walls where moderate rates of seepage are acceptable. If medium to high seepage resistance is required, e.g. cut-off walls for contaminated sites, retaining structures for bridge abutments or tunnels, double sheet piles with sealed or welded joints are recommended.

Sealing systems for watertight sheet pile walls

The following sealing systems are used to increase the watertightness of sheet pile walls:

- bituminous filler: Beltan® Plus, maximal water pressure: 100 kPa;

- wax & mineral-oil-based filler: Arcoseal™, maximal water pressure: 100 kPa;

- water-swelling product: ROXAN® Plus system, maximal water pressure: 200 kPa;

- AKILA® system, maximal water pressure: 300 kPa;

- welding: 100% watertight.

As Darcy’s law for discharge through homogenous structures is not applicable to leakage phenomenon through sheet pile interlocks, a new concept of “joint resistance” has been developed by GeoDelft (Deltares).

Learn more about impervious sheet pile walls

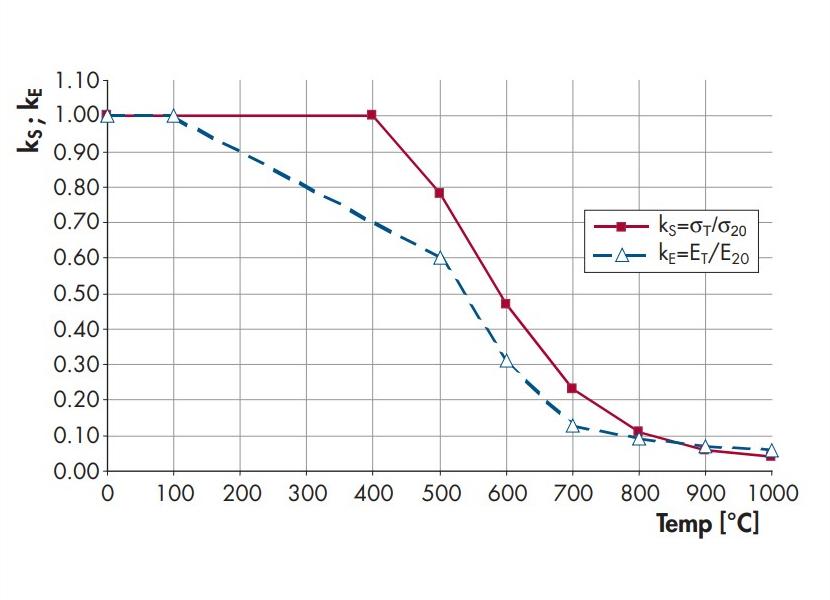

Fire Protection

Fire safety is an important design criteria for steel sheet piles that will be used as permanent structural elements in underground car parks, basements and infrastructure (tunnels, underpasses...). ArcelorMittal carried out extensive research on this subject and can assist with the required fire design verifications.

A comprehensive description of the design is available in the brochure “Underground car parks. Fire resistance” (see below). Furthermore, it includes an easy-to-use verification procedure allowing a simplified assessment of the fire safety of the steel sheet pile structure at the pre-design stage.

ArcelorMittal's R&D department developed years ago a software for internal use that can account for the influence of the (saturated) soil behind the sheet pile wall in case of fire.

Feel free to contact us for more detailed information or for a complimentary preliminary design with our exclusive software.

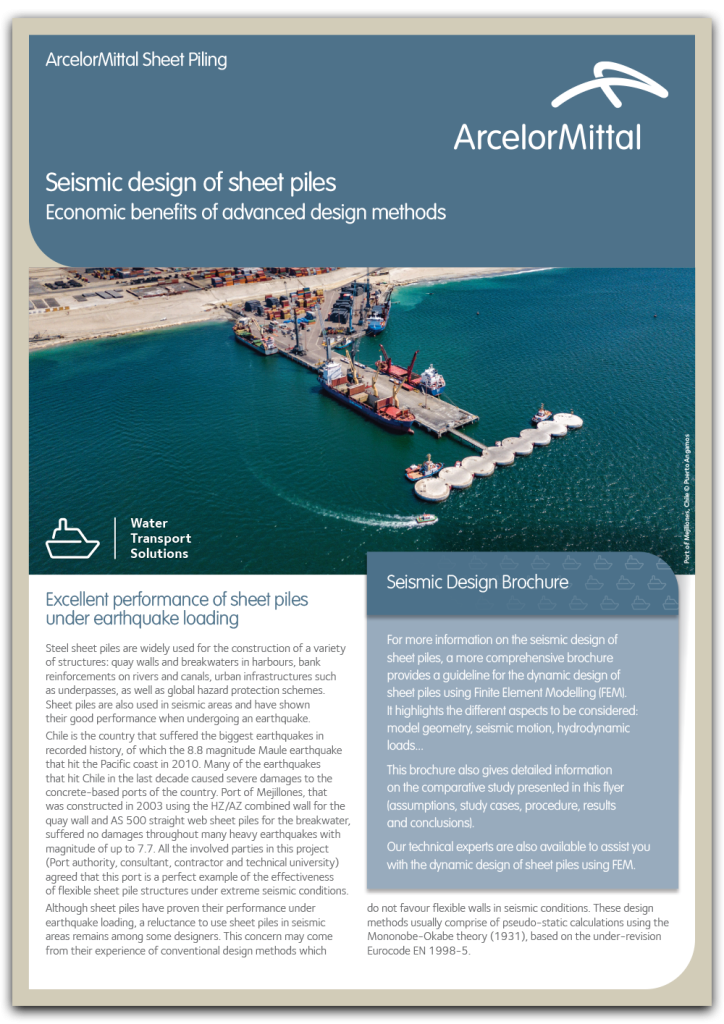

Seismic design

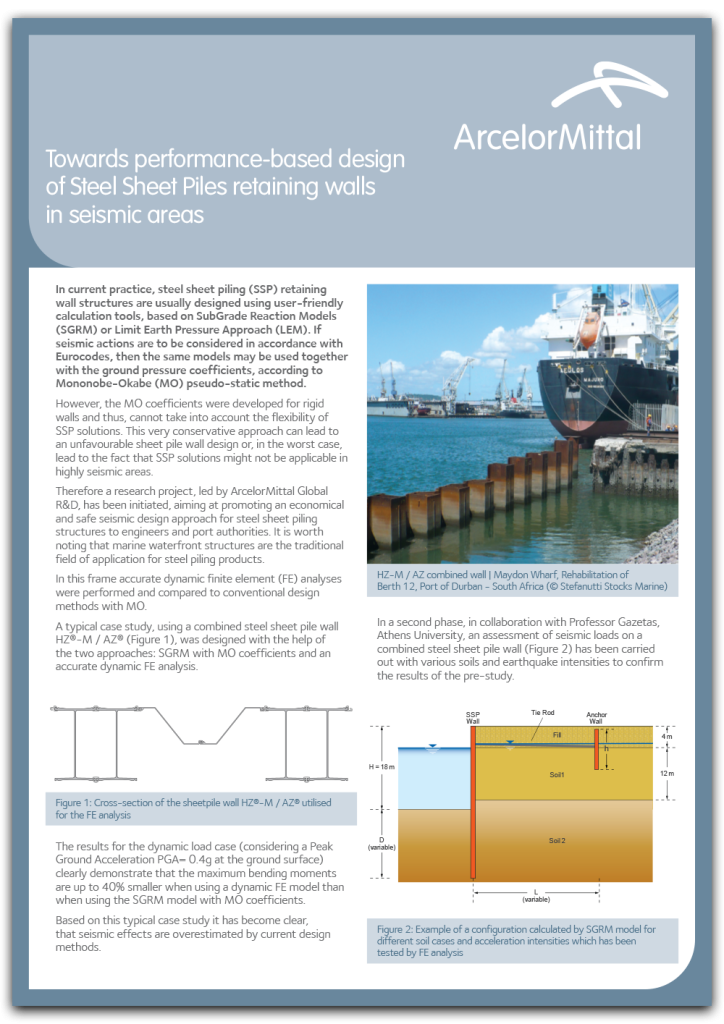

Although sheet piles have proven their performance under earthquake loading in many countries around the globe, a reluctance to use sheet piles in seismic areas remains among some designers. This concern may come from their experience of conventional design methods which do not favour flexible walls in seismic conditions. These design methods usually comprise of pseudo-static calculations using the Mononobe-Okabe theory (1931).

Numerical studies and physical experiments (centrifuge testing) have shown that these conventional methods of design are overestimating the loads on retaining walls, and especially in the case of flexible walls.

Today, powerful design tools using Finite Element Modeling (FEM) allow dynamic calculations that can accurately predict the behaviour of the retaining walls undergoing different seismic loadings. A research project led by ArcelorMittal R&D and a study carried out by world-leading maritime consultant engineering company SENER have shown substantial optimization potential when using these advanced design methods.

Feel free to contact us for more detailed information or for assistance with dynamic design of sheet piles using FEM.

Piling Handbook

9th edition | 2016 - 2022

Downloads

Seismic. Towards performance-design | Flyer | 2017

Performance based design of steel sheet piles in [...]

Seismic design of steel piles | Flyer | 2021

Economical and safe design approaches for steel sheet [...]