Installation

Installation of Steel Sheet Piles

It is possible to drive sheet piles into any type of soil except rock, but steel sheet pile installation is a quite complex topic that should be handled by experienced professionals. Installation shall consider the whole system: sheet pile, soil, pile driving equipment, driving template and if required, driving assistance. Additionally, a piling job can only be successful if it is based on an extensive soil investigation. This is the basis! If you are new in the business, seek help from experienced professionals before you start, especially for the installation of king pile systems and circular cells.

The selection of the sheet pile size must be based on the static design and on driveability in the given geological conditions. Installation speed and the allowable environmental impact on the surrounding area will depend also on the type of piling equipment.

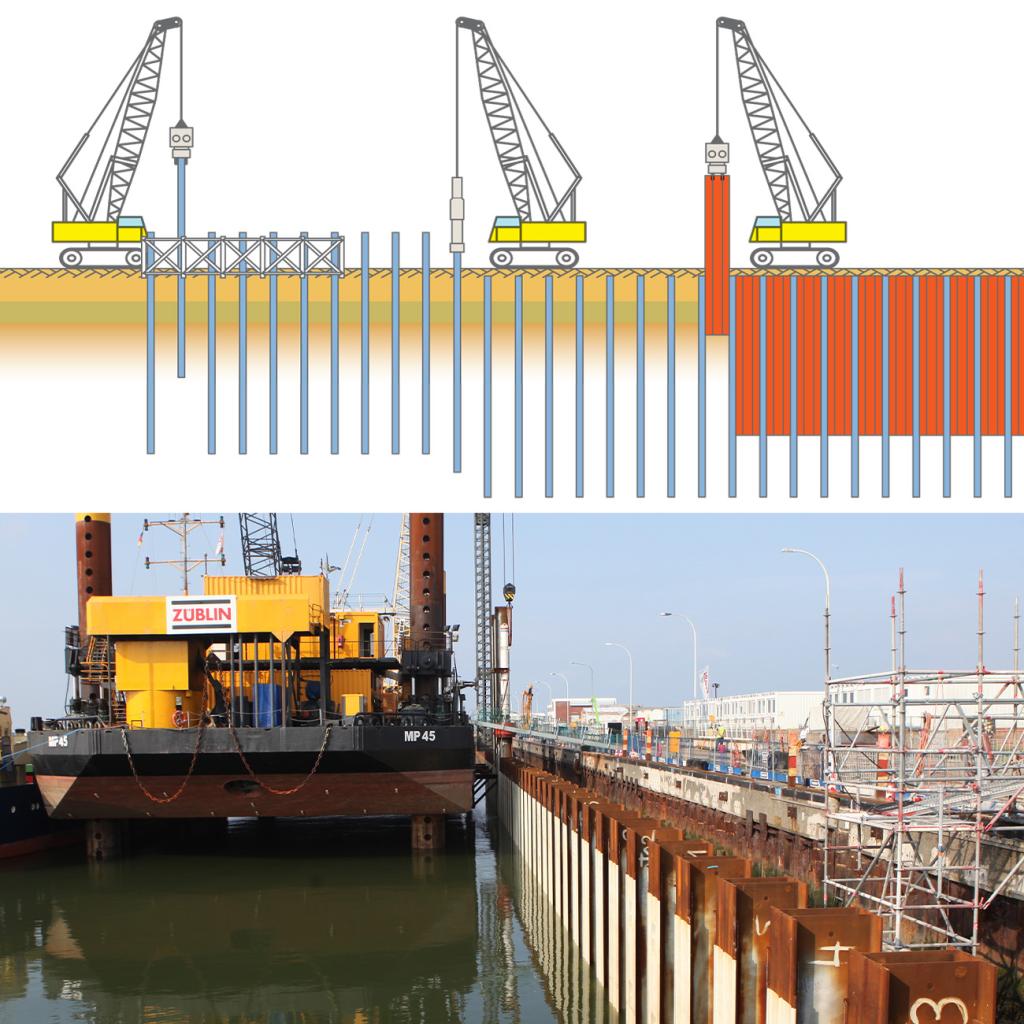

Today the standard installation techniques use:

- vibratory hammers;

- impact hammers;

- presses.

Driving assistance is either water-jetting, pre-drilling or pre-augering, blasting (quite rare).

Special installation techniques in different ground conditions

Other special installation techniques exist and can be beneficial if certain site conditions prevail.

Execution speed varies significantly with ground conditions, sheet pile length and driving equipment. Generally speaking, the execution speed of standard sheet piles lies anywhere between 6 pairs and 30 pairs a day.

Execution of circular cells or diaphragm cells using AS 500 sheet piles is more complex (see link to our webpage below).

The installation of an HZ-M combined wall system must follow a specifc procedure. It requires a rigid two-level template, or a driving equipment fixed to a leader and a guiding frame.

For details on these more specific installation methods, see our Piling Handbook, our AS 500 brochure, and our Installation Guideline.

Installation guide

Here you can find all necessary information about installation of sheet piles

Installation equipment

The choice of the pile driving equipment shall consider the whole system: sheet pile, soil, driving template and if required, driving assistance, nuisances (noise & vibrations). Additionally, a piling job can only be successful if it is based on an extensive soil investigation. It is possible to drive sheet piles into any type of soil (except rock), but steel sheet pile installation is a quite complex topic that should be handled by experienced companies.

The selection of the sheet pile size must be based on the static design and on driveability in the given geological conditions. Installation speed and the impact on the surrounding area will depend predominantly on the type of piling equipment.

Installation method

There are several ways to install steel sheet piles into the ground. The main parameters to consider are: soil conditions, sheet pile section and length, driving equipment, permanent vs. temporary wall, visible wall (coatings for aesthetics), installation tolerances (vertical, position,...), interlock sealing systems used, ...

Sheet piles can be driven into any soil except rock. The installation method and equipment must consider the system, and a thorough soil investigation is necessary for a successful piling job. In Nordic countries, rock-bolting is commonly used when the sheet pile depth is inadequate to activate the required passive resistance of the soil.

Downloads

Installation of steel sheet piles

This manual is a comprehensive guide to the installation of steel sheet piles