HZ-M system

HZ®-M king piles, HZ®-M Solutions, HZ®-M Combinations, RZ/RH Connectors

The HZ®-M steel wall system

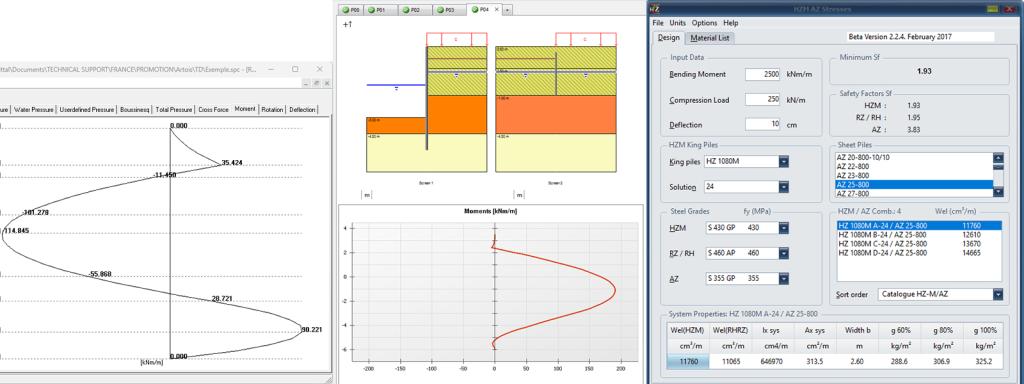

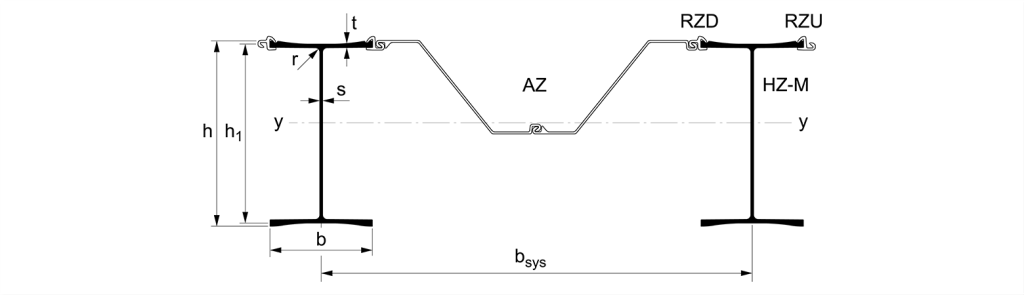

(HZ-M/AZ)

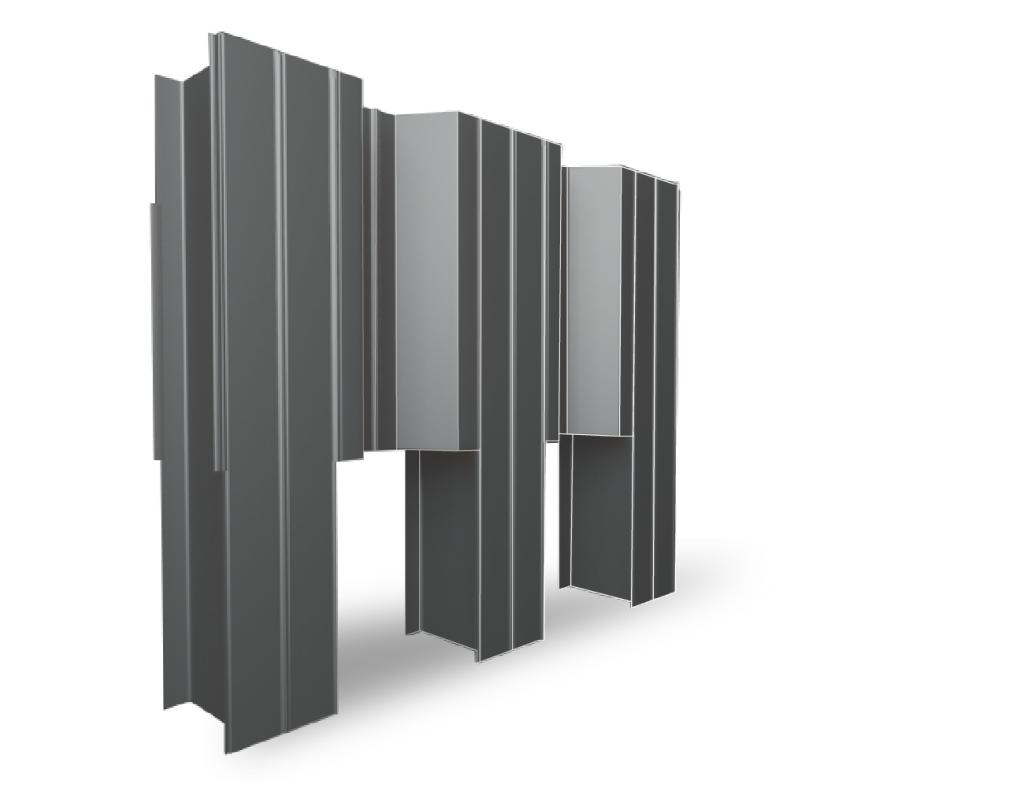

The HZ-M Steel Wall System is a combined wall created by the combination of several elements. It replaced the older HZ system in 2008, and comprises following elements:

- HZ-M king piles (primary elements), a special wide flange beam with a specific flange geometry, and a width of 420 mm or 460 mm;

- AZ infill sheets (secondary or intermediary elements), standard corrugated steel sheet piles;

- special hot rolled connectors (RH, RZD, RZU) connecting infill sheet piles and HZ-M king piles to guarantee a continuous wall.

This system has a high bending resistance and stiffness. The king piles can also be used as bearing piles submitted to high vertical loads, e.g. loads from cranes on quay walls. The intermediary sheet piles (or "infill sheets") act mainly as soil-retaining and load-transferring elements. Their main task is to transfer the horizontal loads (soil pressure, water pressure,...) to the king piles, and are usually between 60% and 80% of the length of the king piles.

Technical database

Consult our products characteristics

The HZ-M/AZ systems achieve very high stiffness and high bending moment capacity. Depending on the combinations and steel grades adopted, the bending moment capacity can reach more than 21 000 kNm/m (equivalent elastic section modulus Wel up to almost 46 500 cm3/m).

The numerous available combinations are based on the same principle: one structural support comprising 1 or 2 HZ-M king pile sections, alternating with a lighter intermediary double AZ sheet pile. There are also combinations without AZ infill sheets. Note that the infill sheet shall always be one AZ double pile.

Infill sheets are generally shorter than the HZ-M king piles. Depending on soil conditions and additional design criteria, such as durability, AZ infill sheets have usually a low section modulus (typically AZ sections with an elastic section modulus Wel up to 3 000 cm3/m).

Hot rolled RZD, RZU and RH connectors threaded and partially welded to the HZ-M king piles allow a mechanical connection with the AZ infill to form a continuous wall.

ArcelorMittal manufactures a series of four HZ-M profiles, and three of them can be rolled in three or four different thicknesses. Additionally, there are six different ‘solutions’ for each HZ-M section.

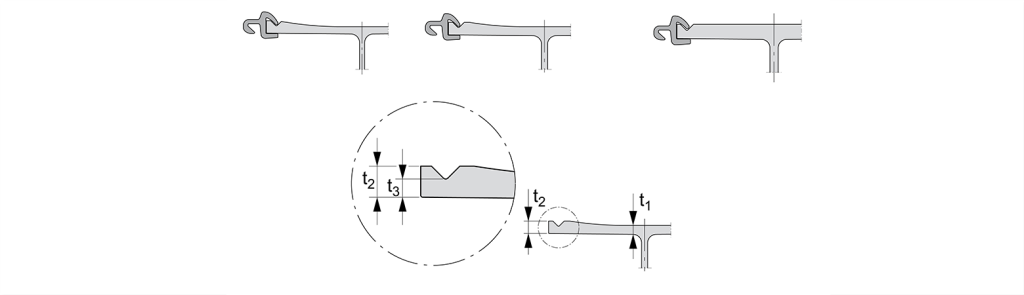

One of the key features of the HZ-M king pile is the concave geometry of the flanges of the lighter HZ-M sections, as well as the unmatched flange thickness of the heavier king piles. To thread the RH/RZ connectors, a groove is milled into the flange (patented process).

The milling equipment guarantees very tight tolerances of the shape of the groove, which improves the minimum interlock hook connection and ensures a sufficient residual steel thickness t3 on the flange (see picture). Note that the groove is milled only if required, i.e. sol. 12 and sol. C1 have only grooves on one flange.

HZ®-M king piles

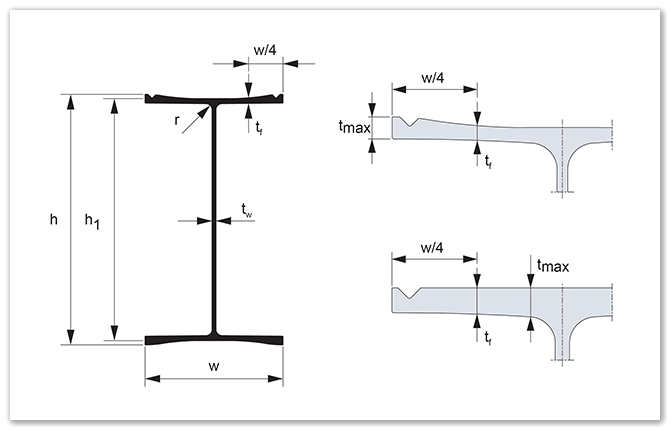

The HZ-M king piles are stiff wide flange beams, with a width of 420 mm or 460 mm, a height up to 1 100 mm, and flange thicknesses up to 40 mm, used in the HZ‑M/AZ combined wall system.

The key feature of this special sheet pile is the milled groove at the edge of the flanges that allows threading specific hot rolled connectors on it. The development of this range was made specifically to match the higer requirements of the deep sea quay wall for JadeWeserPort in Wilhelmshaven, Germany, back in 2008. The HZ‑M has been patented by ArcelorMittal.

Structurally, the HZ-M king piles fulfill 2 different functions

- as retaining members, the king piles resist horizontal loads resulting from earth and water pressures,

- as bearing piles, the king piles transfer high vertical loads from the superstructure, i.e. crane rails, building foundations, etc, to the ground.

The intermediate AZ sheet piles have a closing function, retaining earth and water, but they transfer most of the loads to the king piles. Infill sheet piles shall be exclusively a pair of light AZ sections because they have sufficient flexibility to adapt to the driving tolerances of a combined wall system.

The HZ‑M and their connectors are available in high strength steel grades according to EN 10248, ASTM A572 and ASTM A690.

Notes:

- HZ®, HZ-M® and HZ/AZ® are trademarks from ArcelorMittal

- the milling process of the HZ-M profile has been patented by ArcelorMittal

Update February 2019 and January 2020: we modified slightly the radius r between the flange and the web of the profiles HZ 1080MA and above. It is now 30 mm instead of 35 mm. We updated all the values on our website, in the latest version of the HZ‑M brochure (2020), as well as the AutoCad files. This change has no noticeable impact on the resistance of the profiles, but might have one on the shape of the special T-connectors for tie-rods.

Update October 2019: the new HZ 630M profile completes the existing range of the already large HZ-M series. It was developed mainly for very hard driving conditions (installation in compact soils) and for structures with restrictions on the height of the system. It replaces the HZ 680M LT.

Update November 2021: the radius r of the HZ 880M range changed to 30 mm, consequently the section properties slightly changed. Please check the latest version of the HZ-M brochure (version 2022).

HZ®-M Solutions

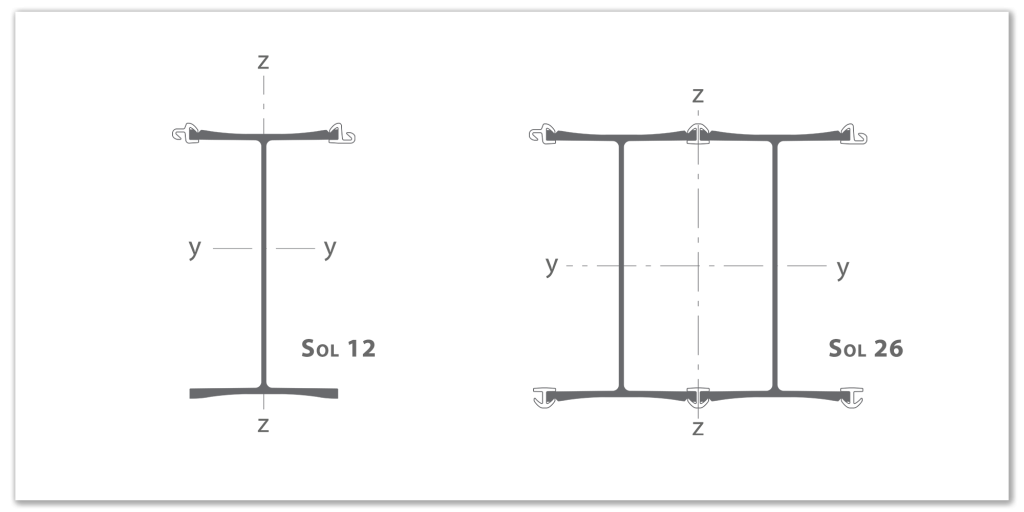

A solution consists of one king pile (HZ-M single or box-pile) and a few connectors. It is the key element (king pile) of a combined wall.

For instance

- solution 12: 1 HZ-M section and 2 connectors (1 RZD, 1 RZU),

- solution 26: 2 HZ-M sections and 6 connectors (1RZD, 1 RZU, 4 RH).

There are 4 different solutions to use with infill sheet piles AZ (Sol. 12, 14, 24 and 26).

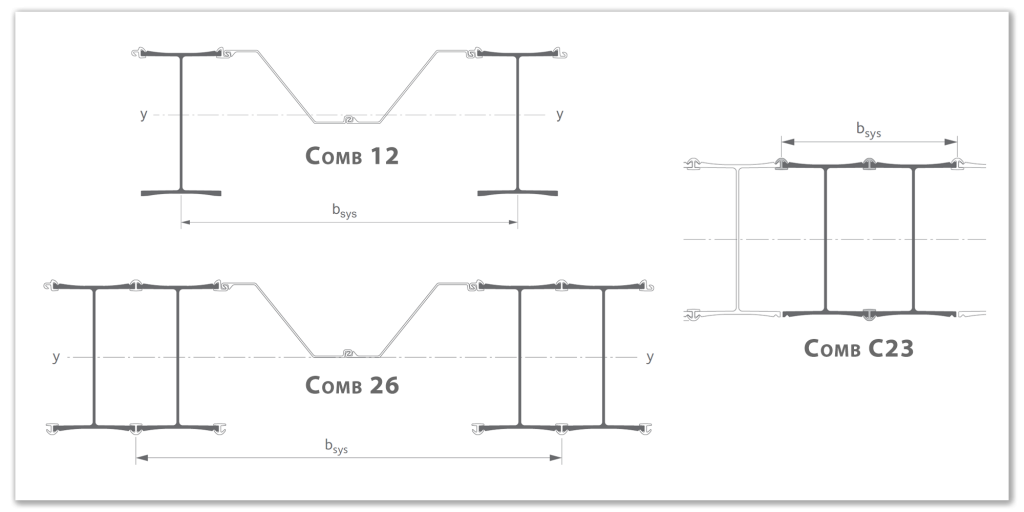

HZ®-M Combinations

A standard HZ-M/AZ combination consists of a king pile (single HZ-M or HZ-M box-pile) and one pair of AZ infill sheet piles.

Combinations C1 and C23 are exceptions: they do not use infill sheet piles.

For instance

- combination 12: combined wall made of 1 single HZ-M king pile and 2 connectors (Sol. 12) and a double AZ infill sheet per system;

- combination 26: combined wall made of a box-pile with 2 HZ-M king piles and 6 connectors (Sol. 26) and a double AZ infill sheet per system;

- combination C1: steel wall made solely of single HZ-M king piles driven side by side, and linked by 1 RH connector;

- combination C23: steel wall made solely of box-piles HZ-M (box-pile = 2 HZ with 3 RH connectors) driven side by side, and linked by 1 RH connector.

There are 6 different combinations, 4 with infill sheet piles AZ (Comb. 12, 14, 24 and 26) and 2 without infill sheets (Comb. C1 and C23).

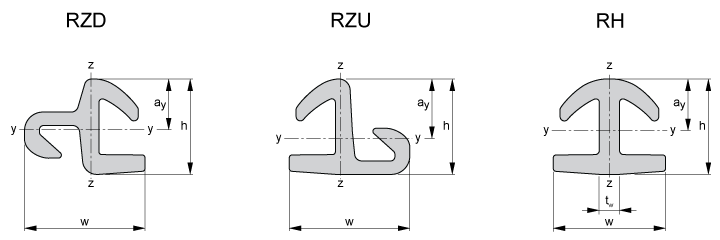

RZ/RH Connectors

The hot rolled connectors RZD and RZU connect the intermediary AZ sheet piles to the HZM king piles to form a continuous wall.

RZD and RZU connectors have on one side a cavity that wraps perfectly around the flange of the HZ-M section with its groove, and on the other side, they are rolled with the same shape as the Larssen interlock of the AZ sections (same rolling tolerances).

The hot rolled connector RH is symmetrical and connects two HZ-M profiles together, in order to fabricate an HZ-M box-pile (solution 24 and 26), or to install a continuous wall built-up with HZ-M profiles exclusively (combination C1 and C23, which yield extremely high section modulus walls).

There are two families of connectors due to the range of thickness of the flanges of the HZ-M series (set A et set B).

Connectors are partially welded to the HZ-M on the mill’s premises. The thickness and length of the welds depend on soil conditions and project specific factors. Typically, connectors are welded over a minimum of 10% of the length, with a reinforced weld of 500 mm (19.7") at the top and tip. Connectors are welded with a short recess from the theoretical top position of the AZ infill sheets to ease the threading of the AZ on the job-site.

In case of high watertightness requirements, a solution consists in seal-welding the connectors to the HZ-M in combination with a sealing system applied to the Larssen interlocks.

Connectors are usually as long as the AZ intermediary sheet piles, which are generally between 60% and 80% of the length of the HZ-M.

Discover our comparative case studies of HZ®-M system

Our projects