Design of steel sheet piles

Methods and Considerations for Designing Steel Sheet Piles

There are several methods to design a sheet pile wall. Below is short description of the most common methods.

In the past, the global safety factor was the rule: one factor applied to the steel sheet piles, and one applied to the geotechnical design (usually applied to the passive resistance of the soil,...). It is known in some countries as the Allowable Stress Design (ASD) for the sheet piles.

The latest Eurocodes are based on a semi-probabilistic approach: EN 1997 - Part 1 (EC 7-1) for the geotechnical design, and EN 1993 - Part 5 (EC 3-5) for the steel sheet piles and bearing piles.

Nowadays, a Soil Structure Interaction Method (SSIM) should be the standard method used to design retaining walls, even though in some European countries the Limit Equilibrium Method (LEM) is still widely used, even for final design of large structures.

Furthermore, for complex structures or in sensitive soils, the Finite Element Method (FEM) is more adequate. In any case, it is of utmost importance to base any design on extensive soil investigation: the more data you have on the soil conditions (soil borings, laboratory tests,...), the better you can optimize the geotechnical design, and the choice of a sheet pile section. Spending a little bit more time and resources on the geotechnical investigation can reduce siginificantly the cost of the structure, but most importantly, reduces the risk of failure.

EC 7-1 is a quite complex standard. There are many new notions, and curiously, there are 3 different approaches for the same design. Each European country can determine which approach is applicable in their country. Besides, some countries, such as France and The Netherlands, have even developed a national standard to complement EC 7-1.

The drawback of a national standard is that design engineers active in other countries may have to cope with different design approaches, which is exactly the problem that should have been solved with the common Eurocodes! Besides, it is more complex for software developers to propose a user-friendly software that can be used in different European countries. There are several issues in this standard, such as the way to deal with water pressure (which partial safety factors should be applied,...). Nevertheless, it is a first step into a unified design method: the basic concept is the same, but it is clear that the final result will depend on the design approach chosen. Which one is more realistic? Nobody knows...

Piling Handbook

Consult our reference book for design engineers

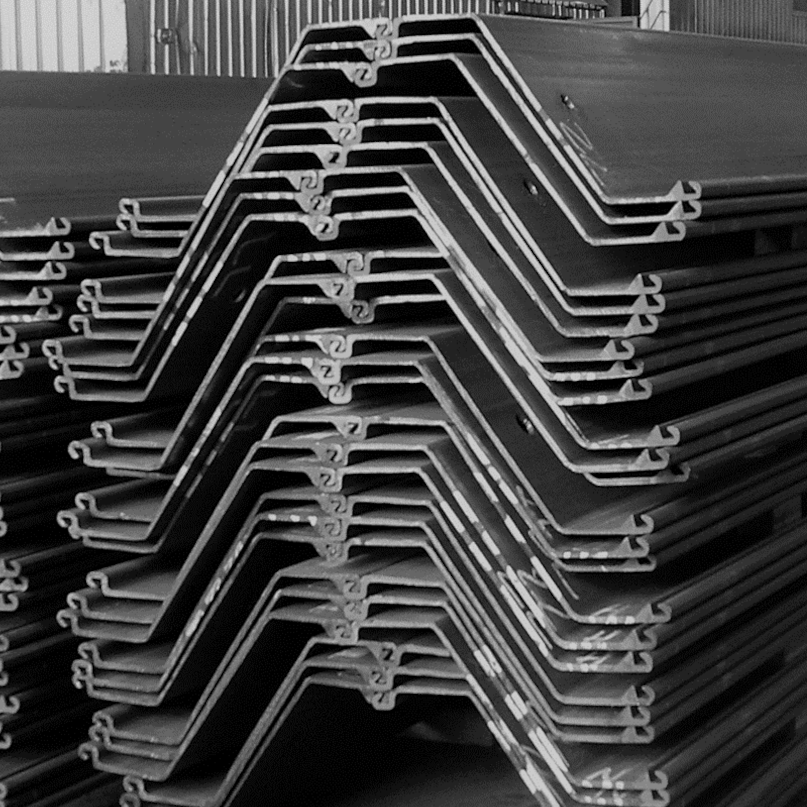

The selection of a sheet pile shall take into account the choice of the steel grade. It has an influence on the classification of the sections, so that it is not possible to give a simple rule covering all the cases, but generally speaking, using a higher steel grade (higher yield strength) leads to a lighter sheet pile, hence to a more cost-effective solution. Note that the additional premium for a higher steel grade is by far offset by the weight reduction of the sheet pile.

Finally, the engineer should take into account the driveability of steel sheet piles, which depends on the soil conditions, length of the pile, driving equipment, permissible deflection / deformation,...

Do not hesitate to contact our engineering department for more detailed information, and check our Piling Handbook, as well as the user manuals of our software AMRetain and Durability.