Engineering

Unleashing the Power of Engineering: Technical Aspects, Design Software, SmartSheetPiles, and Steel Sheet Pile Design

ArcelorMittal Sheet Piles provides an overview of steel sheet pile design, emphasizing various design methodologies such as the Allowable Stress Design (ASD) and the Soil Structure Interaction Method (SSIM). It also highlights the importance of detailed geotechnical investigations in optimizing design and reducing risks. The group at ArcelorMittal Sheet Piles introduces advanced software tools like AMRetain™ and Prosheet, designed for both preliminary and final design phases of steel sheet pile structures. Additionally, the development of ArcelorMittal's SmartSheetPile technology is detailed, showcasing its capabilities in real-time monitoring and predictive maintenance to enhance the safety and longevity of infrastructure projects.

Benefits of Steel Sheet Piles

Think Steel First!

Steel is at the core of sustainable, modern construction. Flexible, strong, and entirely recyclable, steel sheet piles offer versatile solutions for infrastructure projects worldwide. ArcelorMittal combines innovative designs with technical expertise to provide efficient, durable, and environmentally conscious solutions tailored to meet your project's needs.

Key Benefits Across Applications

- Sustainable Ports: ArcelorMittal’s steel sheet piles significantly lower the carbon footprint of port structures, as demonstrated through Life Cycle Assessments (LCA). For quay walls, our solutions are up to 44% more environmentally friendly compared to traditional concrete alternatives, enabling greener and more efficient port operations.

- Underground Car Parks: Steel sheet piles excel in soft soils and areas with high groundwater levels, offering a cost-effective and time-efficient solution for retaining walls. They require minimal space for installation, reducing traffic disruptions and environmental impact. Comparative studies reveal up to an 88% reduction in greenhouse gas emissions compared to other retaining wall methods.

- Bridge Design: Steel sheet pile abutments simplify bridge construction by reducing costs by 8% and construction time by at least 10%. Over a bridge's 100-year lifespan, they lower environmental impact by 36% and emissions by 12%, all while supporting the circular economy with their ease of recovery and recyclability.

- Flood Defense & Bank Protection: For flood defenses and embankments, steel sheet piles provide watertight, stable, and aesthetically adaptable solutions. Whether used in urban or rural settings, they integrate seamlessly into the environment while offering essential protection. Their adaptability supports ecosystem restoration, meeting both ecological and design needs.

Building a Better Future

By choosing ArcelorMittal steel sheet piling solutions, you invest in a sustainable, efficient, and reliable foundation for your projects. Our professional team is dedicated to delivering high-quality support, innovative solutions, and certified sustainability at every stage, ensuring the success of your projects.

Benefits of Steel Sheet Piles

Building infrastructure projects with our innovative solutions and unmatched services facilitates the delivery of global goods right to your doorstep.

Technical Aspects

We address specific technical aspects such as durability, imperviousness of steel sheet pile walls, seismic design, and more. Here are the common issues and solution

Durability | Steel sheet piles, commonly used in permanent earth retaining and foundation works, are durable even in unprotected conditions, although corrosion levels can vary by environment. Typical environments include soil, atmospheric, fresh water, and marine settings, with marine being the most corrosive. Regular monitoring and, if needed, additional protection measures like cathodic protection are recommended for harsh marine conditions. |

Watertightness of Sheet Piles | Steel sheet piles are generally impervious, making them ideal for applications needing water flow restriction, such as underground structures. Sealing systems at interlocks enhance water control, reducing risks like settlement and keeping areas dry. Each sealing choice should consider specific site conditions and requirements. |

AMLoCor® - Steel Grade for Maritime Structures | AMLoCor® steel by ArcelorMittal offers reduced corrosion rates in maritime structures, significantly enhancing durability in critical zones. This "low corrosion" steel is especially beneficial in the Low Water Zone and Permanent Immersion Zone, important for high-stress areas in ports and breakwaters. |

Fire Protection | Fire safety is crucial for steel sheet piles used in underground constructions. ArcelorMittal provides extensive research and tools for fire design verifications to ensure safety in fire-prone environments. |

Seismic Design | Despite historical reluctance, sheet piles are effective in seismic areas. Advanced design methods like Finite Element Modeling (FEM) provide accurate predictions of seismic behavior, offering substantial optimization in seismic design. ArcelorMittal encourages contact for further information on dynamic design assistance. |

Technical Aspects

Enhancing Infrastructure: Key Aspects of Steel Sheet Pile Performance

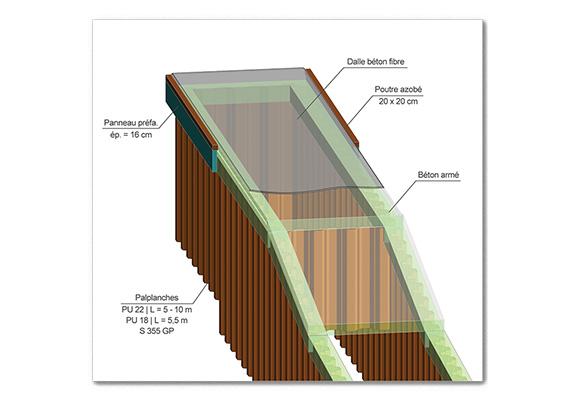

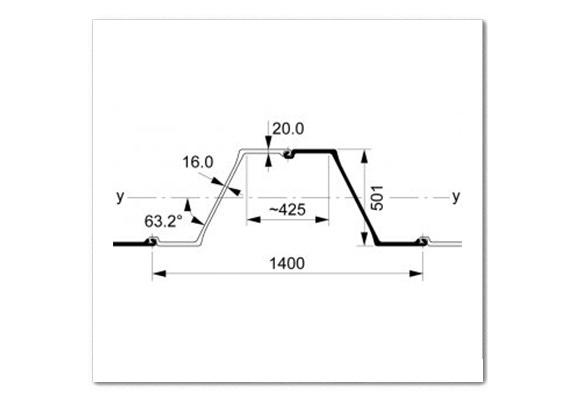

Design of steel sheet piles

Design Methods for Steel Sheet Piles

Steel sheet pile design encompasses traditional and modern methods tailored to specific project conditions. Historically, designs used the Allowable Stress Design (ASD) method with global safety factors. Today, the Eurocodes, specifically EN 1997 - Part 1 for geotechnical design and EN 1993 - Part 5 for steel structures, recommend a semi-probabilistic approach.

Recommended Practices

The Soil Structure Interaction Method (SSIM) is advised for contemporary designs, although the Limit Equilibrium Method (LEM) remains in use, particularly in Europe. For more intricate or sensitive environments, the Finite Element Method (FEM) offers a detailed approach. Effective design heavily relies on comprehensive soil investigations to enhance accuracy and reduce costs.

Key Design Considerations

Design considerations focus on bending moments, steel grade, and specific reduction factors that affect the structural integrity and cost-effectiveness of the project. Engineers also consider pile drivability based on soil conditions, pile length, and installation equipment.

Design of steel sheet piles

Methods and Considerations for Designing Steel Sheet Piles

Installation of Steel Sheet Piles

Steel sheet pile installation is a complex process that requires professional expertise and careful consideration of multiple factors. At its core, successful installation depends on a detailed soil investigation, proper equipment selection, and the integration of all system components, including the sheet pile, soil, pile driving equipment, and driving template.

1. Soil Investigation

A thorough investigation of soil conditions is the foundation of any piling job. This step ensures the selection of the appropriate sheet pile size, installation method, and driving equipment. Installation Techniques

2. Standard installation methods include:

- Vibratory hammers

- Impact hammers

- Presses

Driving assistance methods, such as water-jetting, pre-drilling, pre-augering, or blasting (used rarely), may be required depending on the site conditions.

3. Special Applications

Specific installation techniques are necessary for challenging conditions or specialized projects. For example:

- Circular cells or diaphragm cells require precise execution and a tailored procedure.

- HZ-M combined wall systems demand the use of rigid templates or driving equipment with a guiding frame.

4. Execution Speed

The speed of installation varies significantly, depending on soil conditions, sheet pile length, and equipment. Standard sheet pile installations typically achieve 6 to 30 pairs per day.

5. Equipment Selection

Choosing the right pile driving equipment is essential for minimizing nuisances such as noise and vibrations, while ensuring alignment with soil conditions, driving templates, and any necessary assistance methods.

Comprehensive Guidance Available

For more information on installation methods and guidelines, consult our

These resources provide detailed instructions for standard and specialized techniques, ensuring optimal results for your project.

Installation of Steel Sheet Piles

Installation Equipment and Methods

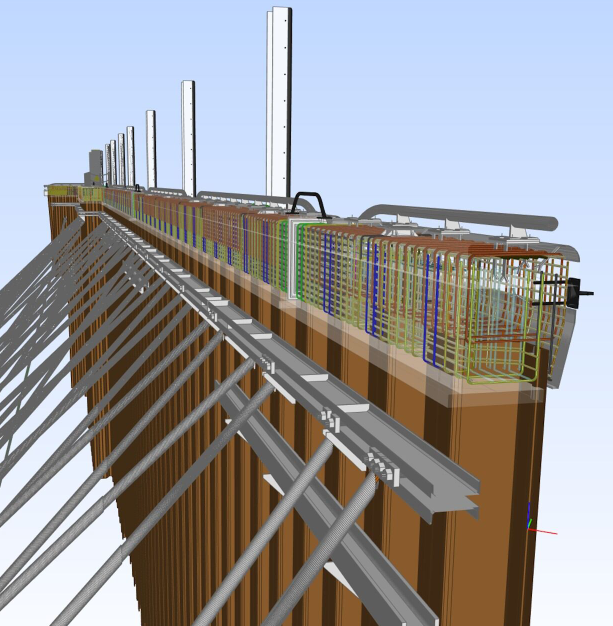

BIM and AutoCAD® for Steel Sheet Piles

Building Information Modelling (BIM) is transforming the construction industry by enhancing collaboration, reliability, and efficiency throughout the design and execution phases. At ArcelorMittal Sheet Piling, we provide BIM and AutoCAD® resources to streamline the design process and support the successful integration of steel sheet piles into infrastructure projects.

BIM

Our technical department has developed BIM objects for Autodesk® Revit® software, including Revit families for standard steel sheet piles (AZ, AU, PU, GU) and the AS 500 series. These objects are available for free download and are designed to improve the productivity of BIM modelers using Revit. BIM enhances collaboration and interoperability across design and management software, and we believe all major steel sheet pile projects will soon be managed through BIM technology.

AutoCAD®

We also offer AutoCAD® files in .dwg and .dxf formats for ArcelorMittal’s full range of steel sheet piles. These files include single and double pile options, which can be easily imported into AutoCAD. Our technical department can assist in optimizing the layout of your sheet pile wall free of charge. Contact us for any support with the files.

BIM objects & AutoCad® files

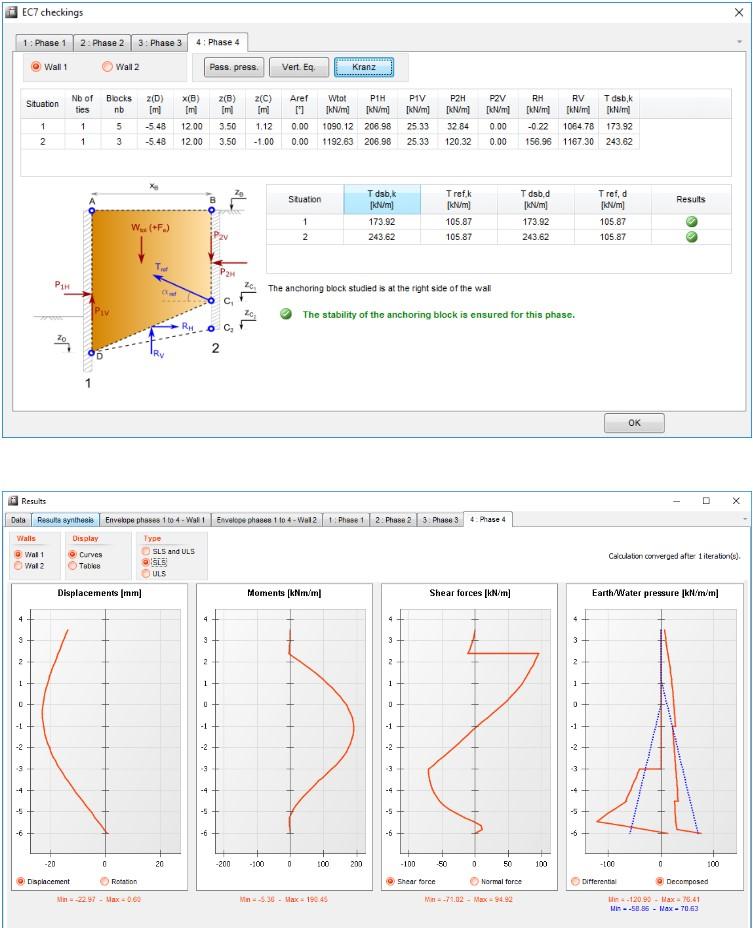

Design Software

Design Software for Retaining Walls

ArcelorMittal offers advanced software solutions like AMRetain™ and Prosheet for designing steel sheet pile structures. Prosheet is ideal for simpler, smaller projects, while AMRetain™ accommodates more complex designs using European standards and the Subgrade Reaction Model (SSIM). These tools cater to both preliminary and final design needs, bridging simple methods like the Limit Equilibrium Method (LEM) with more sophisticated approaches like Finite Elements Method (FEM).

Comprehensive Assistance and Tools

Our technical team, equipped with diverse technical and cultural expertise, provides comprehensive support throughout all design phases at no extra cost. We aim to ensure the sustainability and success of your projects.

Software Availability

- AMRetain™: Versatile and user-friendly, this software supports a variety of wall types and includes simulation capabilities for different construction phases. It is competitively priced, covering distribution and support costs.

- Prosheet: Based on the LEM and ideal for preliminary designs, especially for cantilever and single supported walls.

- Durability Software: A free tool that helps select the optimal steel sheet pile section, incorporating environmental considerations and the latest design methodologies.

- VLoad®: Specializes in designing concrete capping beams, compliant with European standards.

- HZM AZ Stresses: Analyzes stress for combined wall systems, offering easy solution selection and basic material listing.

All software, including Durability, HZM AZ Stresses, Prosheet, and VLoad, are available for free download and suitable for personal, commercial, and enterprise use.

Design Software

AMRetain™, ProSheet, Durability, VLoad®, HZM AZ Stresses

SmartSheetPile

ArcelorMittal is at the forefront of digital transformation in the steel industry, creating more efficient, safe, and sustainable solutions with SmartSheetPile, a cutting-edge health monitoring system. This innovative technology integrates real-time sensor data with digital tools to create digital twins of infrastructure, enhancing safety and operational awareness.

SmartSheetPile equips infrastructure with sensors that monitor conditions like shocks, corrosion, wall integrity, deformation, and strain.

These capabilities allow for:

- Shocks: Real-time tracking of impacts to identify damages and responsible parties, facilitating claims for compensation.

- Corrosion: Continuous monitoring using various sensor types such as ER probes, ultrasonic sensors, and corrosion coupons to measure thickness loss and predict service life.

- Wall Integrity: Ensuring correct interlock during installation to maintain wall robustness.

- Deformation: Alerting to significant shifts indicating potential failures or damage.

- Strain: Monitoring ongoing strain to assess forces impacting the structure and adjust maintenance plans accordingly.

Data is continuously transmitted to the cloud, allowing for immediate alerts in case of critical events like anchor failures or earthquakes. SmartSheetPile's integration with Artificial Intelligence enhances asset management through predictive maintenance, utilizing advanced algorithms to forecast issues and optimize maintenance schedules. This proactive approach reduces costs, extends infrastructure lifespan, and improves efficiency.

An online monitoring dashboard provides access to a comprehensive digital twin model, displaying detailed sensor data and historical records, enhancing decision-making and operational efficiency.

SmartSheetPile

Smart steel solutions for innovative infrastructures