AZ sections

AZ®, AZ®-700, AZ®-770, AZ®-750, AZ®-800

AZ® sections

Z-type sheet piles are the preferred choice for permanent applications. Among the essential characteristics of Z-shaped sheet piles are the continuous form of the web and the specific location of the interlock symmetrically on both sides of the neutral axis. These two attributes have a positive influence on the section modulus. The AZ® series combine a section with extraordinary characteristics with the quality-proven Larssen interlock. Z-shaped sheet piles present the following advantages:

- extremely competitive section modulus/mass relation;

- lighter than U-piles when comparing sections with equivalent properties;

- increased inertia and thus reduced deflection allowing the choice of high yield strength steels for the most economical solution;

- large width resulting in high installation performance and enhanced watertightness.

ArcelorMittal rolled the first AZ sheet piles beginning of the 1990's. It was at that time an awesome achievement to roll 600 mm wide Z-type sheet piles with a Larssen type interlock. The AZ range was completed with the manufacturing in 1998 of the AZ 48, the heaviest Z-section in the world (outperformed only in 2016 by a new AZ section).

A few years later, in 2004, we launched the AZ-700 wider and lighter sheet piles. Note that these piles are 700 mm wide. The first section was the AZ 38-700, a monumental success. We were indeed the first manufacturer in the world able to roll such wide sections on a regular basis.

Since then, we observed a steady increase in demand for wider and lighter sheet piles. After extensive finite element simulations, optimisations and driving tests under real conditions, we were proud to introduce in 2015 the latest AZ new generation of even more cost-efficient, up to 800 mm extra-wide sheet piles!

All our AZ steel sheet piles have the proven Larssen interlock.

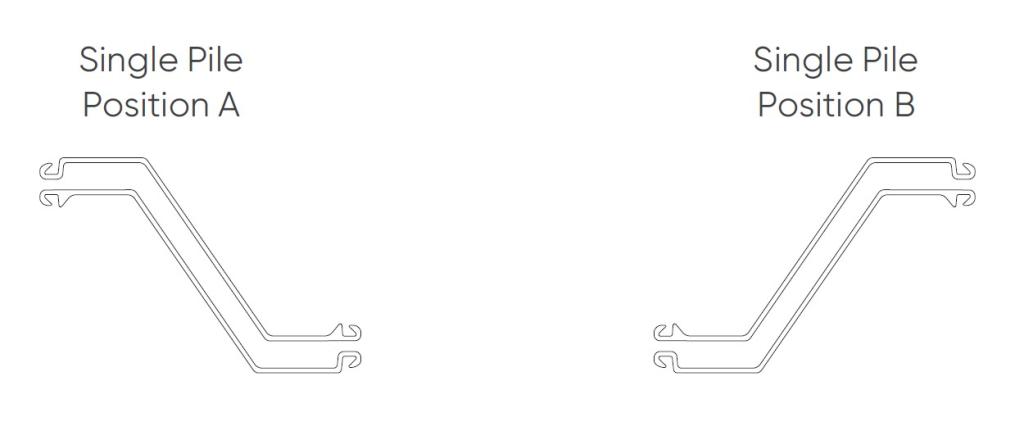

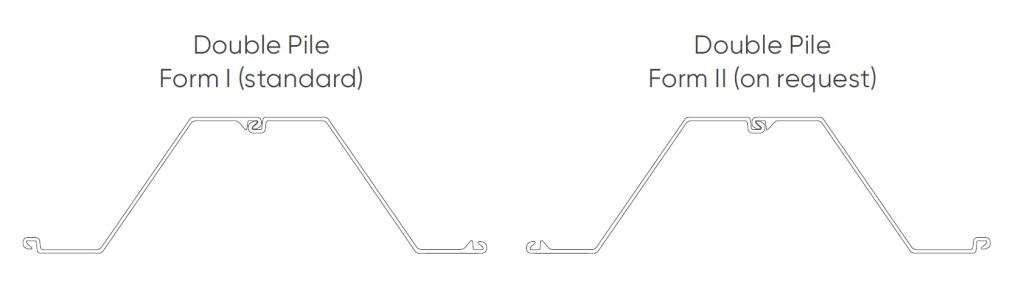

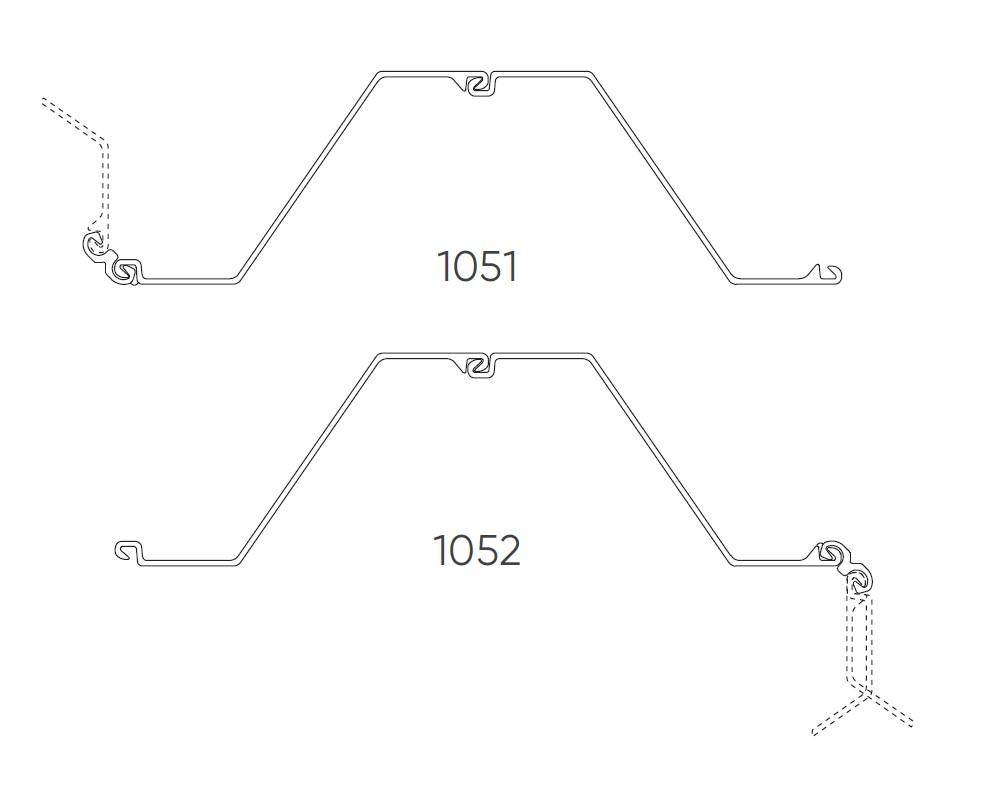

AZ sheet piles are usually supplied and driven as double piles (some exceptions apply). Although statically not required, the common interlock can be crimped (standard pattern), thus improving the straightness of the wall and reducing noise when driving with a vibratory hammer.

Available profiles:

Not yet convinced about the advantages of the new AZ generation: check the brochures below.

Note:

- AZ® is a registered trademark of ArcelorMittal

Technical database

Consult our products characteristics

Interlock

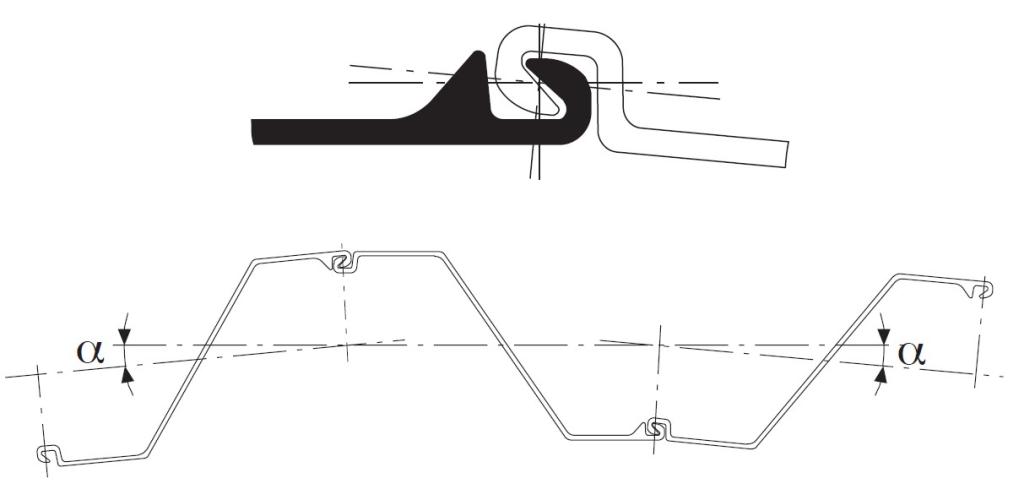

AZ Larssen interlock in accordance with EN 10248. All available AZ sheet piles can be interlocked, as well as the AU, PU and GU (except GU-400). Theoretical interlock swing: αmax = 5°

Delivery form

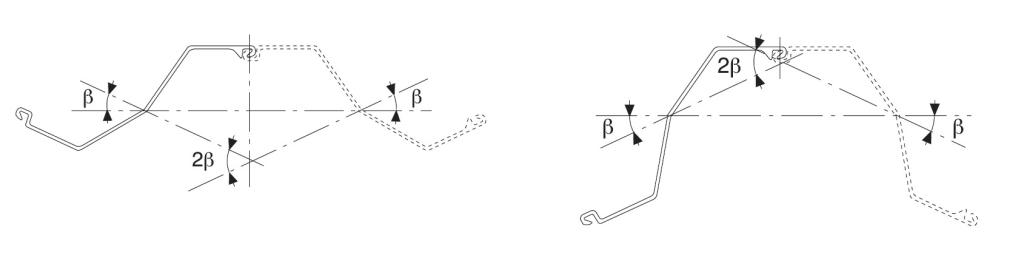

Bent piles

Maximum bending angle: β = 25°. Z-piles are usually bent in the middle of the web. They are generally delivered as single piles. Double piles are available upon request.

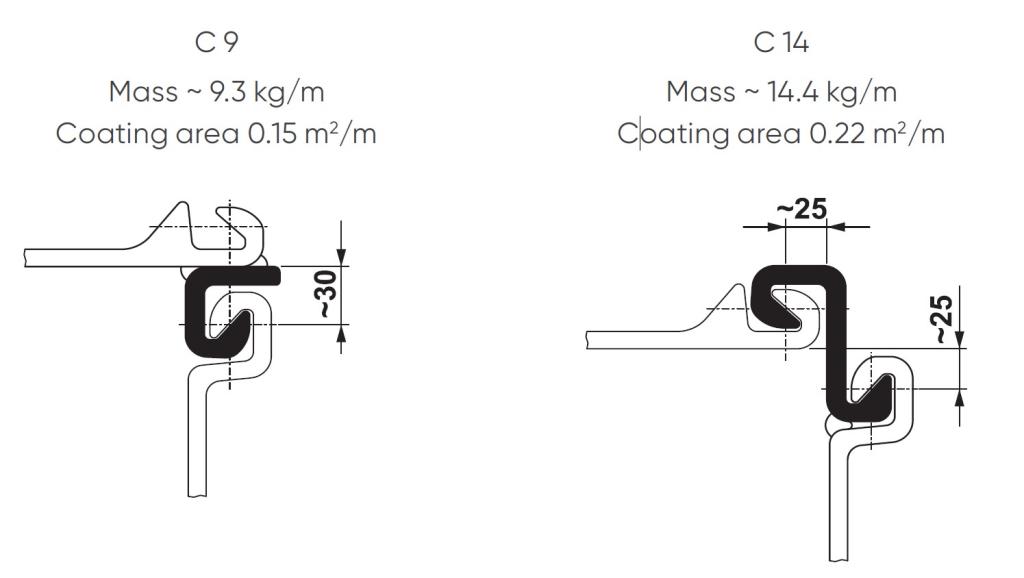

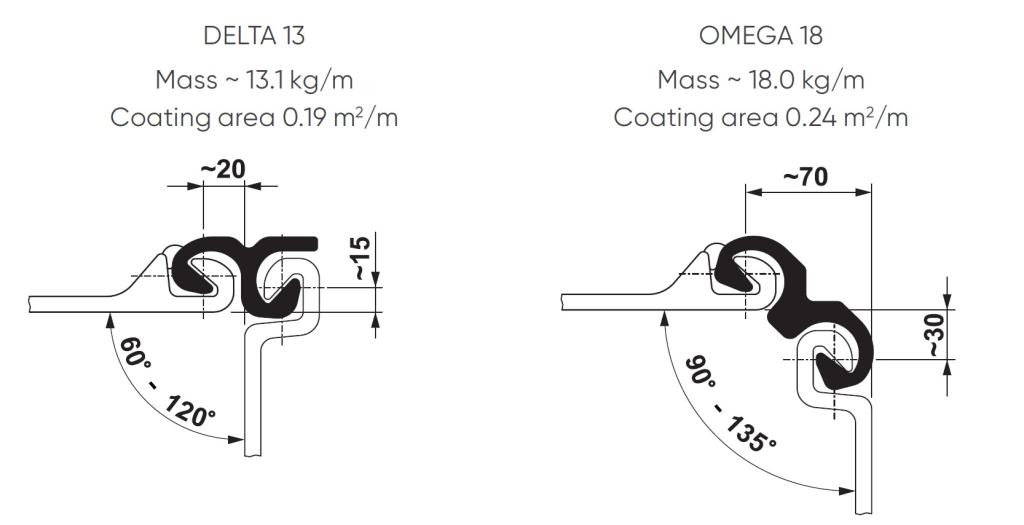

Corner sections

Special corner sections interlocking with U and Z-sections make it possible to form corner or junction piles without using fabricated special piles. Corner sections are fixed to the sheet pile in accordance with EN 12063.

Different welding specifications are available on request. The corner sections are threaded and welded with usually a 200 mm setback from the top of the piles.

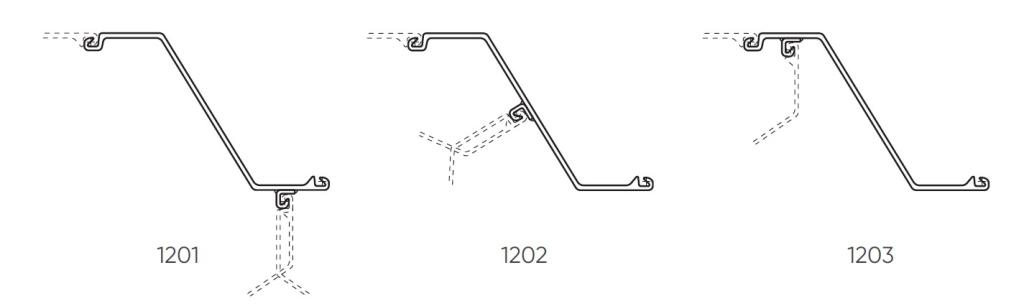

Corner and junction piles

The following special piles, among others, are available as single and double piles on request.

Our projects

Learn more from real practical cases

AZ-800

After the successful market introduction of the AZ-700 sheet pile range and 10 years of proven track record, ArcelorMittal has taken a further step in the development of wider Z-piles.

As a result, the AZ-800 range has been presented to the market in 2015. Intensive testing before market introduction showed that installation can be performed with standard pile driving equipment. However, the optimum choice of a sheet pile section requires a more rigorous analysis of the soil conditions.

Nowadays, the existing ArcelorMittal sheet pile range allows designers and contractors to choose amongst a variety of profiles to best cater for the particular site conditions. Soil characteristics and driving methods are closely linked and have to be considered carefully.

Going wider! The new AZ® sheet piling series by ArcelorMittal As the world leader in the production of hot-rolled sheet piles, ArcelorMittal makes it a priority to pass on the benefits of its research to its customers. Innovation is key to maintaining ArcelorMittal’s position as the partner of choice for products that continuously raise the standard of performance and response to real market needs.

Since 2004, ArcelorMittal has observed a steady increase in demand for sheet piles with a width of 700 mm. This is why, after extensive finite element simulations, optimisations and driving tests under real conditions, we are proud to introduce a new generation of even more cost-efficient, extra-wide sheet piles up to 800 mm wide!

1. Research & Development

The new AZ® series is the result of ArcelorMittal’s extensive experience and ongoing commitment to developing new products. Building on the Group’s steelmaking know-how, research was carried out into optimising to a maximum the weight, dimensions and general properties of the sheet piles. This was only possible through a great effort in stretching the technical limits of the mill’s equipment. The complex theoretical design aspects were handled by the R&D department in collaboration with the University of Stuttgart.

2. Investments

State-of-the-art sheet piles require state-of-the-art production facilities. In order to further improve its product range, ArcelorMittal has invested substantially in the highly specialized rolling mill in Belval, Luxembourg. Thus maintaining it as the world’s leading production site for hot-rolled sheet piles. New straightening equipment is the key element of this investment.

3. Production

Roll pass design activities are concentrated at the R&D Center in Esch-sur-Alzette. Their main mission is to determine the geometry of the rolls in order to be able to produce a correct shape within the allowed tolerances. During the development phase R&D used finite element software to perform numerical simulations of the rolling process, showing the step by step deformation from the semi-product into the finished product. Reduced-scale tests in a laboratory were then carried out to confirm the numerical results. Finally, prior to the industrial production phase, rolling trials have been carried out in order to set up a stable manufacturing process.

4. Sales Feedback

"My overall experience with the new AZ-800 generation is very positive. Our first driving test with these wider sheet piles showed that we can achieve a smoother and quicker installation with our existing equipment. I see a bright future for the AZ-800 range as it can be used in a more time and cost-efficient manner with no additional investments needed."

Eric Leemans Technical Director Soetaert n.v.

In light of the continuous improvement of our products, ArcelorMittal relies on the detailed information provided by our customers based on their experience in the field. The launch of the lighter, wider and more cost-efficient AZ® series was decided due to encouraging feedback from customers that will join us in this new adventure.

Are you interested in installing AZ®-800 & AZ®-750 profiles?

Download our installation guideline AZ®-800 & AZ®-750