Flood defence and bank protection

Sheet pile walls - effective solutions for building and enhancing flood defences and canal banks

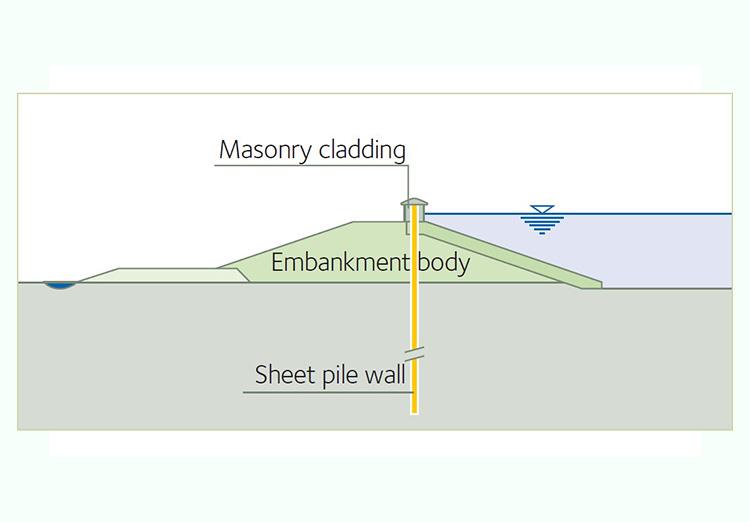

Sheet pile walls can be used in a variety of ways for flood defence systems or for bank protection. For new embankments they can ensure watertightness, support, and stabilization. They are also used to strengthen existing embankments. When space is an issue, e.g. in ports or urban areas, sheet pile walls can form freestanding floodwalls.

The following examples constitute the seeds from which clients, designers, and engineers can grow creative solutions, and are by no means an exhaustive list of the possibilities for using sheet piles in embankments.

Download the document

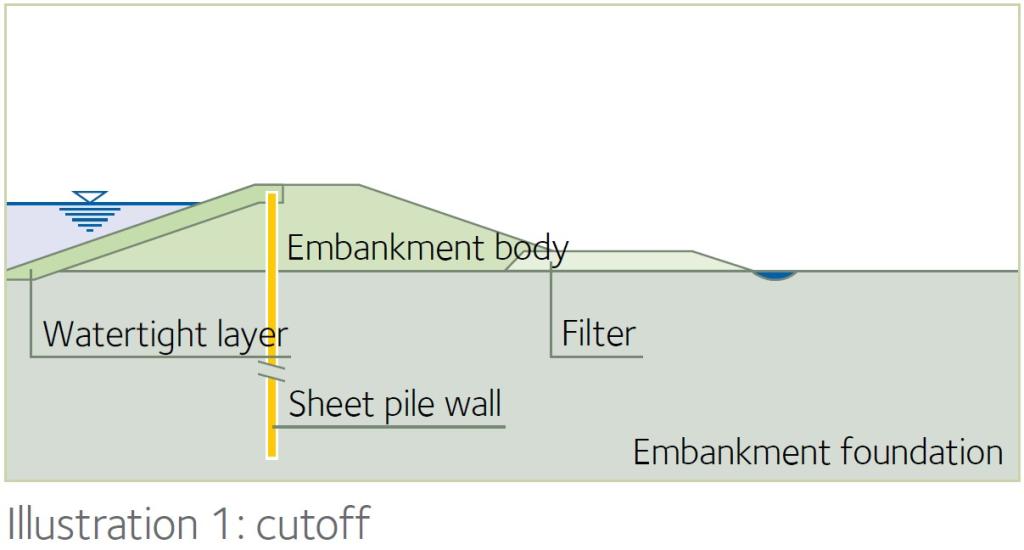

Sheet pile walls in flood embankments can serve as a cutoff to reduce leakage and improve stability. They can be made watertight through natural deposition of soil or by introducing sealing systems. Sheet piles also stabilise the inner shoulder and crest by intersecting slip circles, while the outer shoulder is stabilised by lowering the seepage line. Weep holes can be added to recreate natural flow and prevent drying out. Sheet pile walls also eliminate the risk of erosion by animals or tree roots.

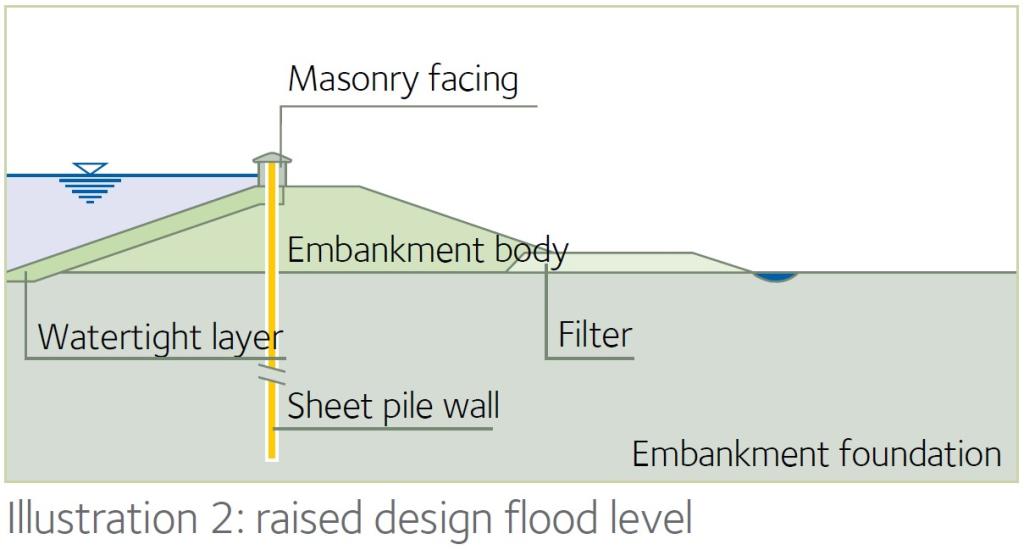

A sheet pile wall can hold back a larger design flood without requiring more landtake by projecting the required height above the crest. This saves on the embankment footprint. Cantilevered sheet pile walls are strong enough to transfer high water pressures into the embankment below. They also stabilise the inner shoulder and lower the seepage line in the outer shoulder.

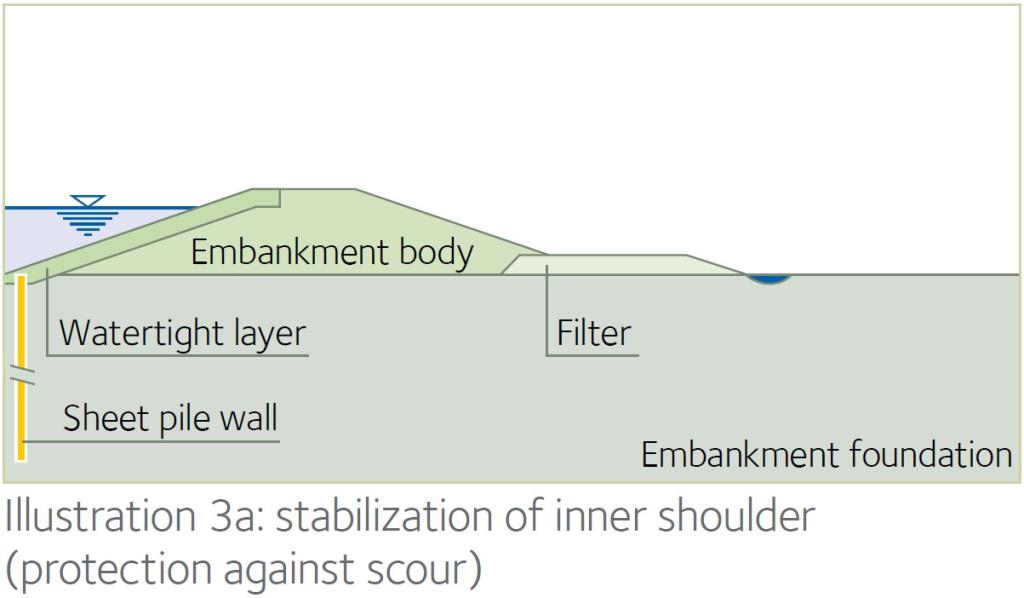

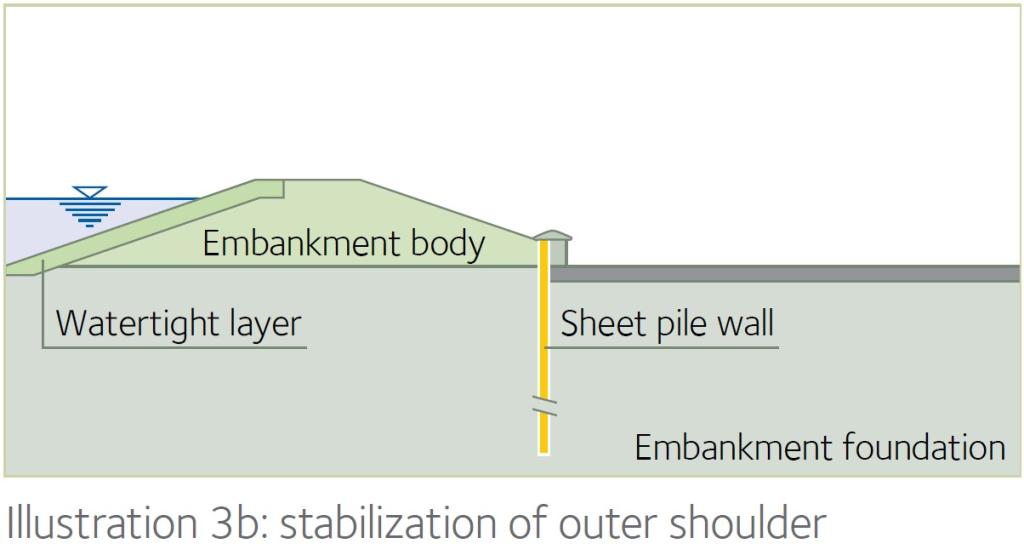

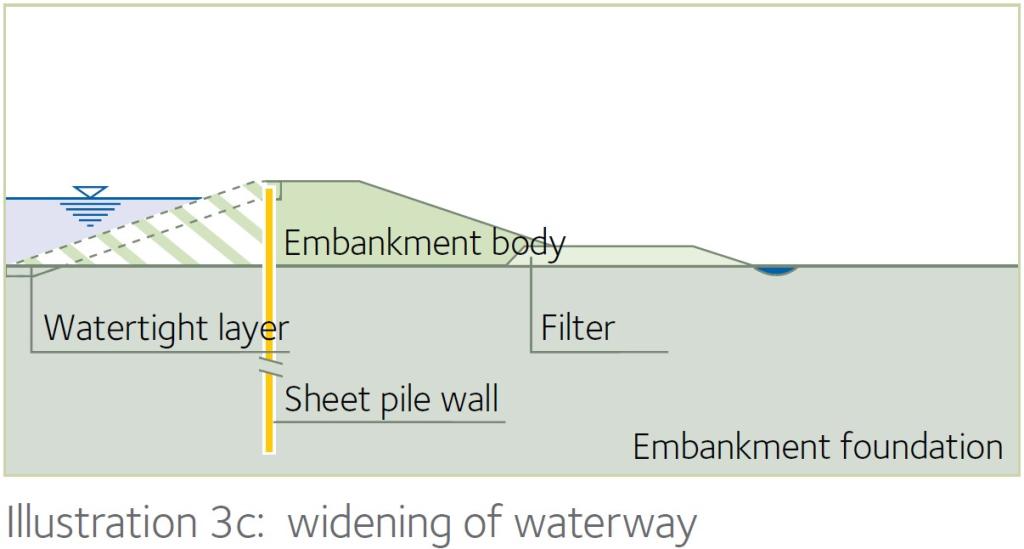

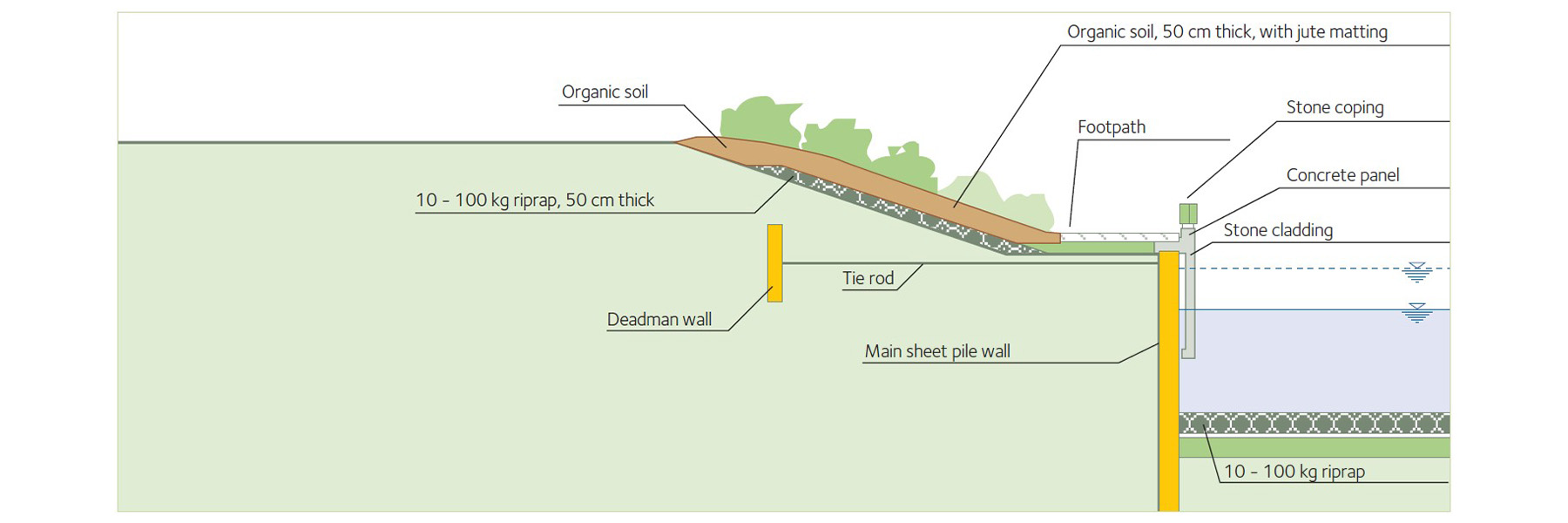

Sheet pile walls at the embankment toe play an important role in slope stabilization by directing the earth pressure of the shoulder into the foundation. This can be achieved by simply driving the sheet piles to a sufficient depth. If the soil height retained by the sheet pile wall is greater than three or four metres, it might be required to anchor the wall. Depending on the space available and the characteristics of the subsoil, the anchor force can be met by a deadman wall, prestressed ground anchors, or batter tension piles. The embankment shoulder stabilised in this manner can therefore be steeper than would be possible without a sheet pile wall. This solution makes for substantial space savings. And if the waterway is to be widened, sheet pile walls mean the bank profile can be vertical, not sloping.

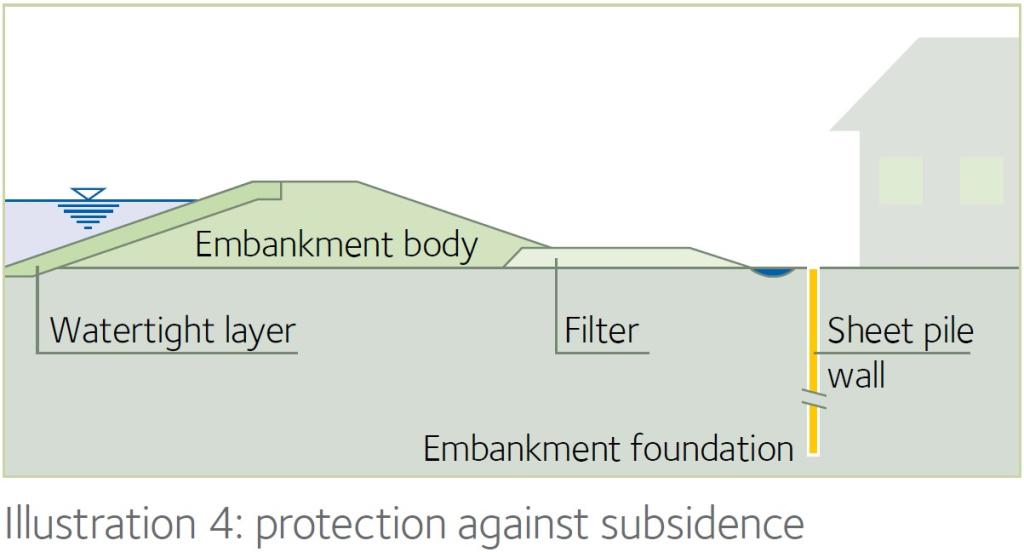

Sheet pile walls can also protect buildings from subsidence. In this case the sheet pile wall is driven outside the embankment. Nearby buildings are thus isolated from the embankment, thereby eliminating the most unfavourable interactions between it and them.

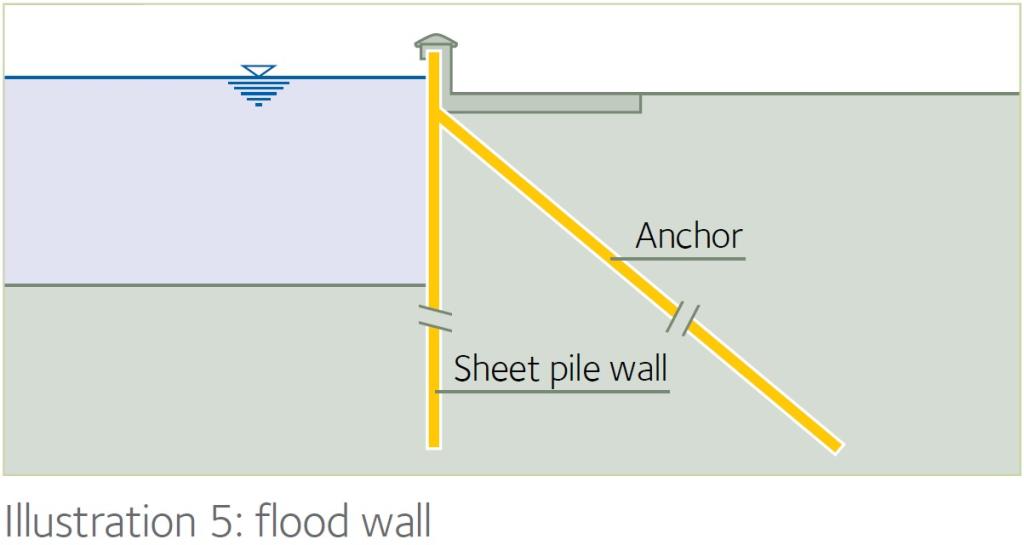

As a flood wall, a sheet pile wall can simply replace a flood embankment, without any reduction in performance. This option is of particular interest in ports or other locations where space is limited. It can also be used to protect isolated buildings, etc. In addition, a flood wall made of steel sheet piles can be connected to an earth embankment without the slightest problem.

Sheet pile walls – a highly advantageous constructive solution

For flood defence and canal-bank protection, sheet pile walls have a number of advantages.

The sheet pile wall technique - the ideal choice

When choosing sheet pile sections, account must be taken of criteria with respect to both strength and the installation procedure. If the sheet piles are intended to form simply a watertight barrier, i.e. without any earth-retaining function, the choice of profiles will be based exclusively on installation and watertightness criteria. If, on the other hand, the sheet pile wall fulfils an earth-retaining function, the choice of profile will be based primarily on its geometrical characteristics. Obviously the designer will take account of other criteria (type of soil, installation procedure, etc.) which will determine the maximum sheet pile lengths that will not give rise to driving problems.

Structural behaviour

Together, the cross-section of an embankment and the profile chosen for a sheet pile wall will elicit a number of possible solutions. These will depend on whether the project is for flood defence or bank protection, and on the characteristics of the site. It is therefore impossible to list design methods with universal values here. This chapter serves chiefly to present a series of fundamental principles which design engineers can bring to bear on their project.

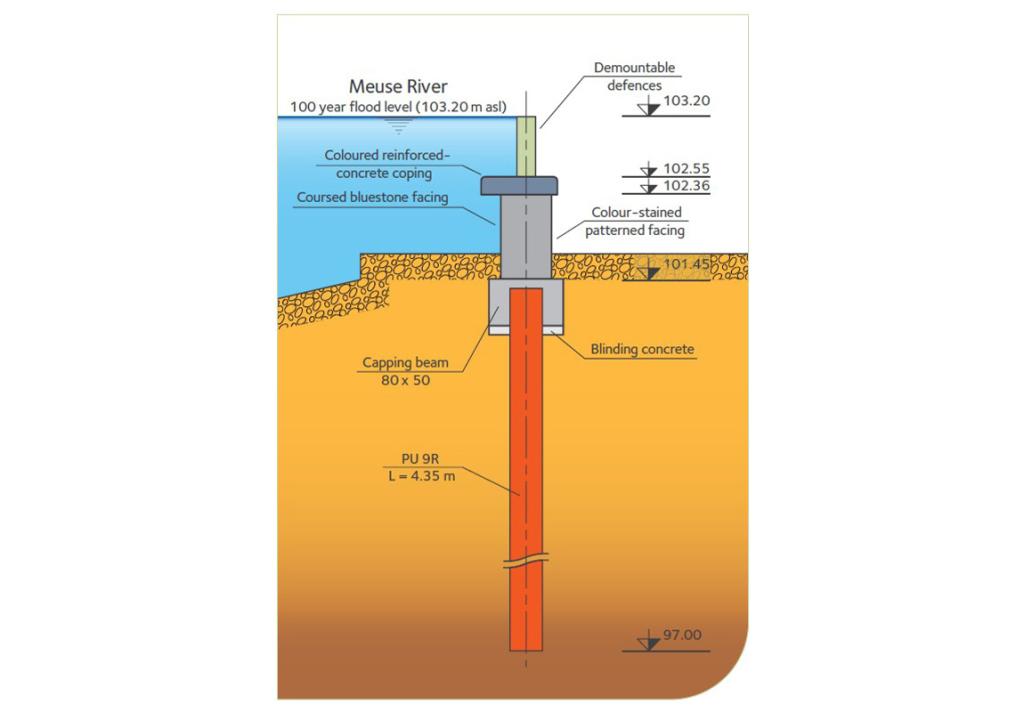

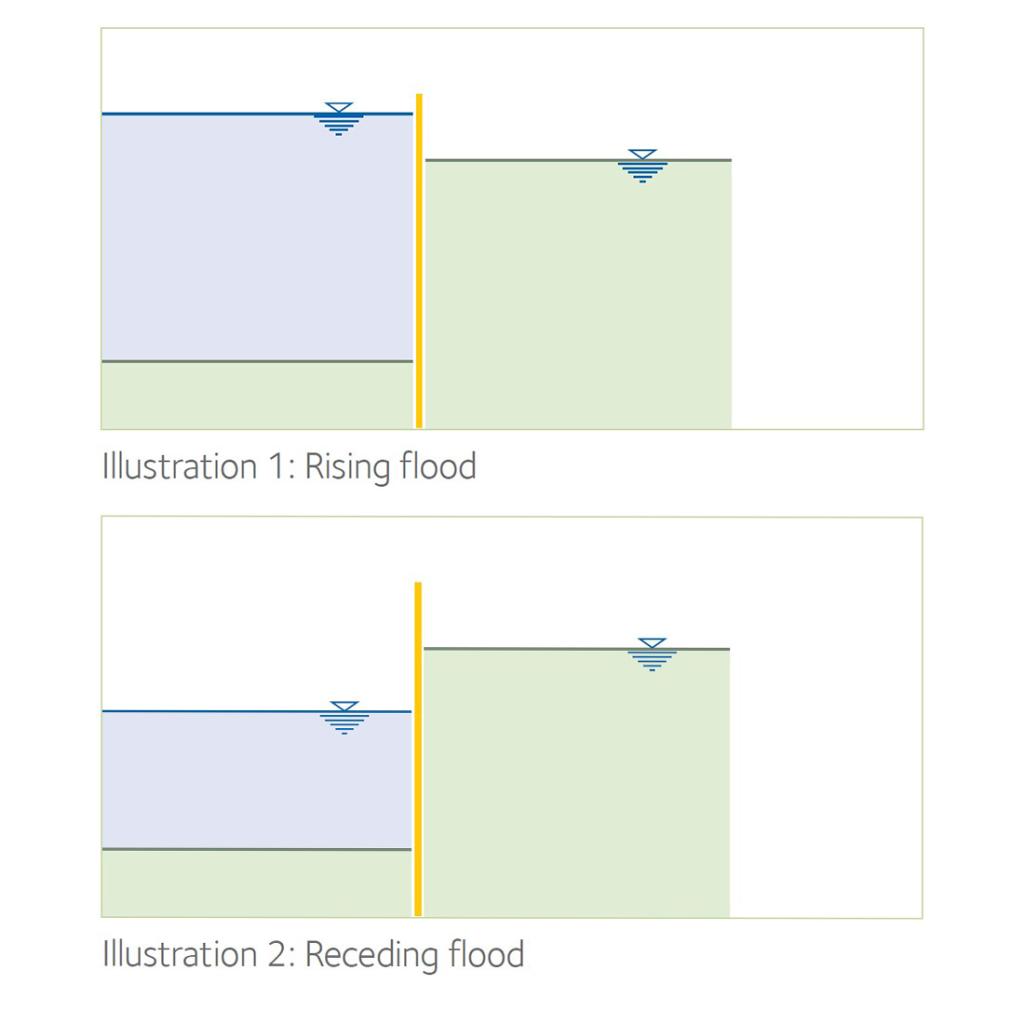

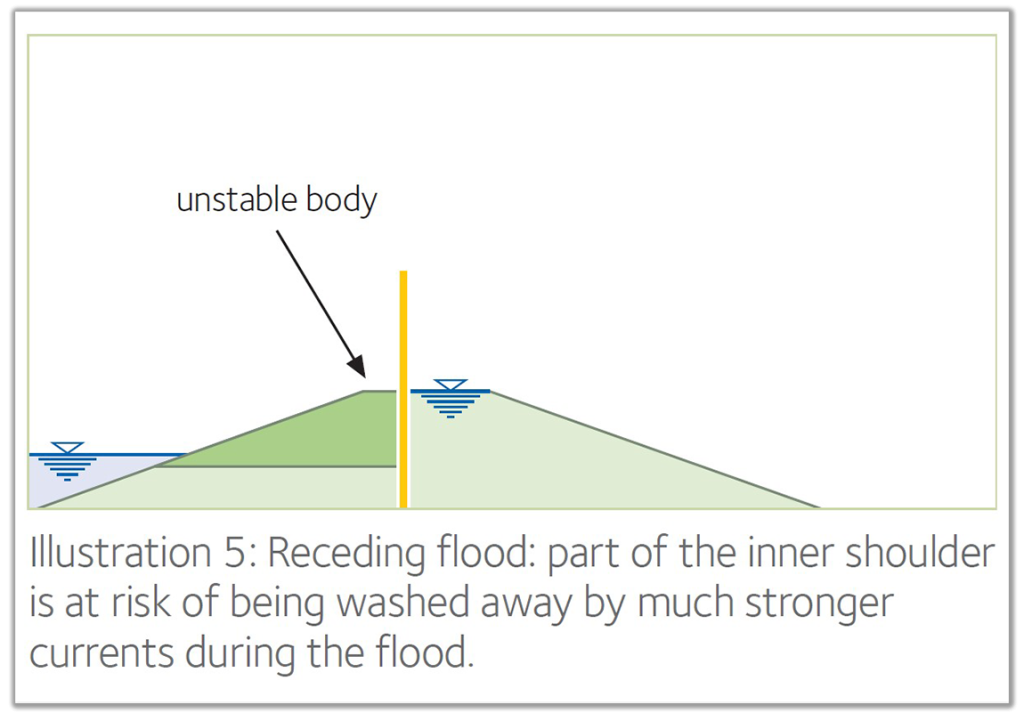

The loads to which a sheet pile wall is exposed generally consist of pressures exerted jointly by earth and water. As far as hydraulic pressure is concerned, an analysis restricted to the design flood (ill. 1) is generally insufficient. Strength and stability are often governed by rapid drawdown of water after a relatively long period of flooding.

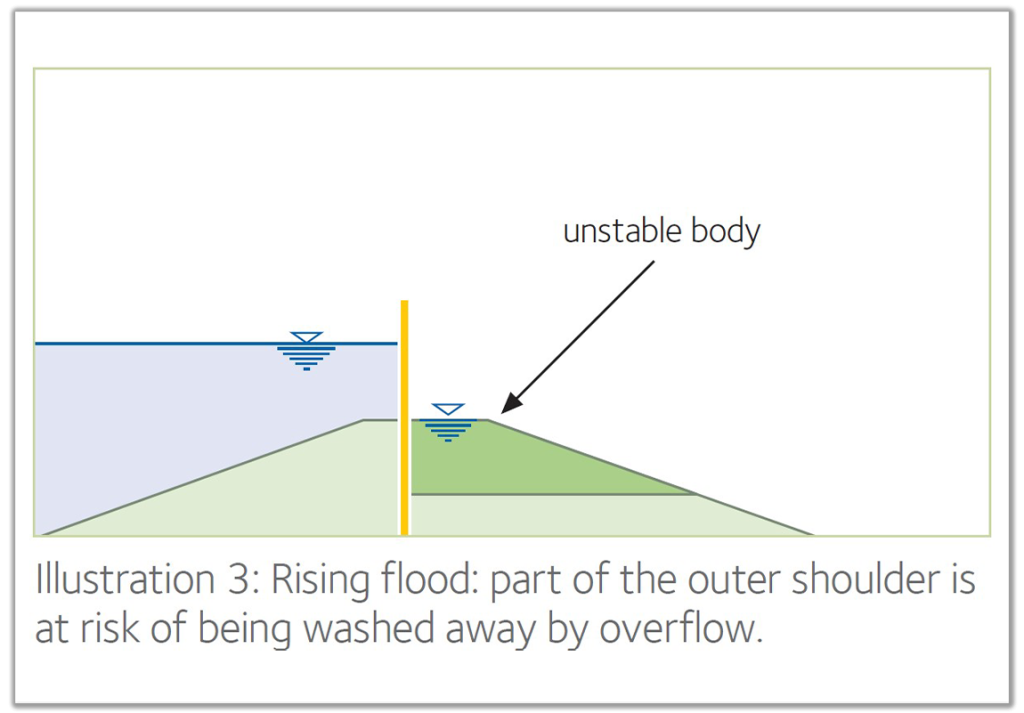

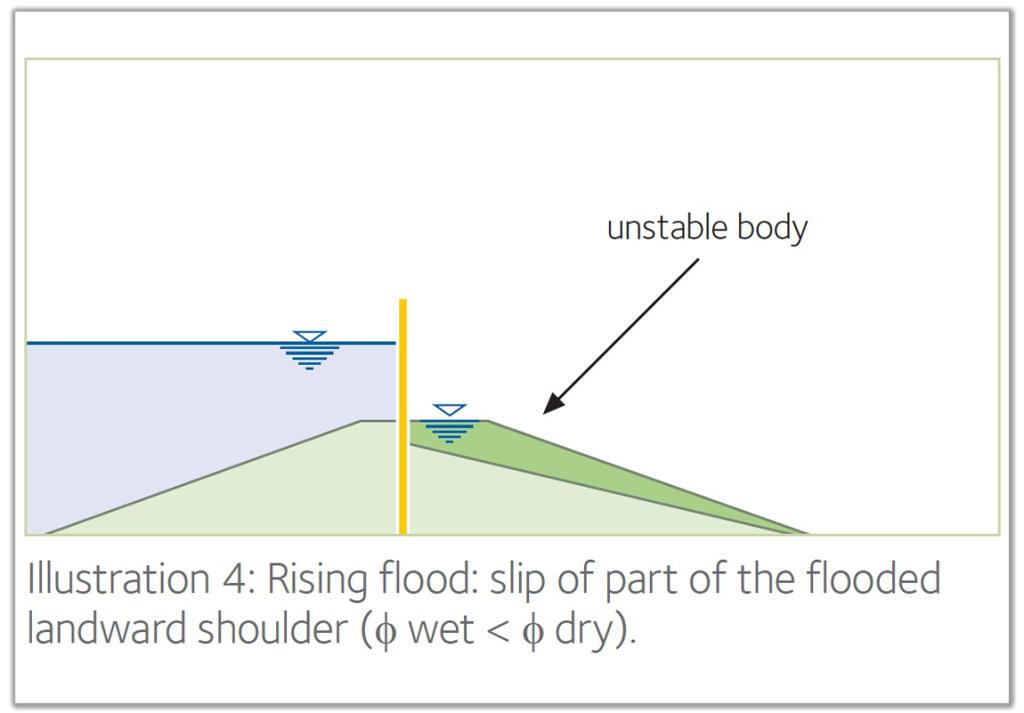

This is illustrated in the second load case (receding flood, ill. 2) where the danger of hydraulic failure of the foundation could prove to be determining for the design of the sheet pile wall. It is prohibited to consider for the design any material on the passive resistance side that could be carried away in extreme cases (ill. 3 - 5).

In addition to purely static stabilization, a sheet pile wall can also – indirectly - produce beneficial effects on the overall stability of an embankment:

- Lowering the seepage line enhances the stability of the outer shoulder which can consequently be steeper or optimised in other ways,

- Lengthening the seepage line enhances safety with respect to the risk of hydraulic failure,

- In the event of a leak through the impervious layer, a central sheet pile wall prevents the migration of fines, thereby preventing backward erosion in the landward shoulder. In addition, the wall significantly reduces the risk of piping caused by burrowing animals.

These additional positive effects are achieved above all when the sheet pile walls are socketed into an impermeable soil layer.

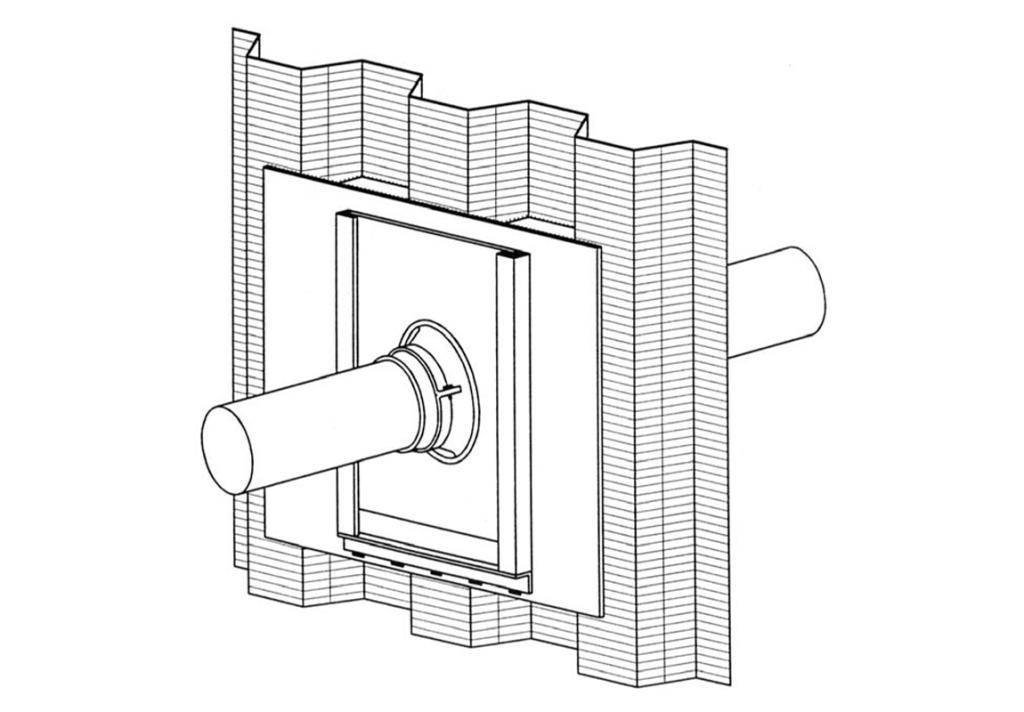

Impermeability

The degree of impermeability of sheet pile walls can vary widely, depending on whether or not interlock sealing systems are used and on the types of sealants. More information regarding this aspect can be found in the brochure “The impervious steel sheet pile wall”. If a sheet pile wall is to have an earth-retaining function yet the outer shoulder is to be prevented from drying out, weep holes can be arranged to allow water through (see EAU 2012, R51). Information on calculating flow rates across sheet pile walls can be found in European standard EN 12063, Annex E. It should be remembered, however, that if the sheet pile wall is not socketed into an impermeable soil layer, only numerical calculations can determine precisely the flow rate and seepage line (i.e. finite elements).

Durability

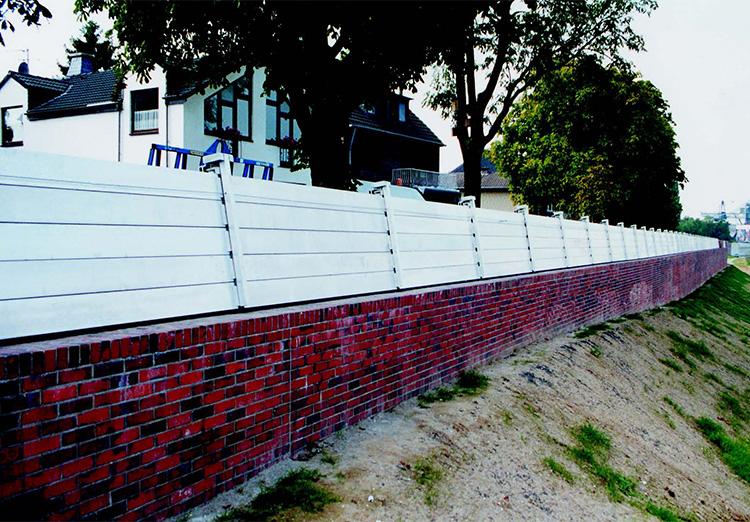

The loss of thickness of a steel sheet pile in the ground is practically zero. Corrosion rates in fresh water are also low. For reasons of aesthetics, though, visible sheet pile walls often receive some form of coating or cladding. Dark colours are recommended, for they soil less quickly. More advice on coating systems can be found in the general catalogue “Steel sheet piles”, in the chapter “Durability”.

Installation

Embankments are vulnerable to settlement and can therefore be affected by vibrations. Disturbance to the embankment can be greatly relieved through the use of state-of-the-art vibratory rigs allowing variable eccentric moment. If there is any doubt, a vibrationlogging system can be used; it emits a warning signal when a given vibration threshold is exceeded. If this occurs, pre-drilling, hydraulic pressing, or impact driving should be used. With impact driving, higher vibration velocities are acceptable in most cases. Hydraulic pressing, on the other hand, does not generate any vibration at all. In all events, if the sheet pile wall is to serve as a cutoff, it is recommended that the greatest care be taken to ensure the integrity of the wall.

Sheet pile walls and landscaping – for creative natural settings

With steel sheet pile walls, the appearance of canal banks can be very natural, meeting not only aesthetic criteria but also economic and ecological requirements. Whether sheet pile walls serve as flood defences or as bank support, they have to fit as seamlessly as possible into the urban or rural landscape. They can be painted, clad with timber, brick, or stone, or masked by plants; suitable planting encourages the reestablishment of ecosystems which can be prejudiced by human intervention in the workings of nature.

Greened banks improve lifestyle quality

Adorned with plants, a sheet pile wall along the banks of a canal will take on attractive and natural attributes. Greening has a positive effect on landscape and the quality of life, especially since the banks of waterways are generally much appreciated as recreational areas. Since greening must take account of the local landscape and ecological requirements, its success will depend in large part on the plants selected.

Ideally, the natural ecosystem should be preserved by modifying it as little as possible and by complementing it in a properly targeted manner. Using sheet pile walls means embankment shoulders can be greened, since there is no risk of the watertight barrier being damaged by roots, etc. In the case of canal embankments, trees mean traffic benefits from a degree of protection from wind. It should be remembered, however, that plants should never be an obstacle to inspection of the embankment.

Just as the balconies or walls of a house can be decorated with flowers in hanging baskets, so can a sheet pile wall be embellished with ‘biotope boxes’. These come in a variety of materials, shapes, colours, and placement possibilities, and can be used in combination.

Biotope boxes can be placed above or below the water line, depending on their purpose, i.e. whether intended for marshland plants, or more strictly aquatic or totally immersed plants. Two kinds are available: one rests against the outermost face of the sheet pile, the other nestles in the sheet pile trough.

Considerations regarding sheet pile integration

The following aspects should be taken into account when cladding and/or greening sheet pile walls:

- A welded steel section or concrete foundation can serve as a support for masonry works.

- When choosing cladding, account should be taken of impact loading on both the water and the landward sides.

- Any cavities caused by water running down sheet pile walls should be filled so that loads are transferred directly to the steel barrier. It is important to prevent accumulation of large volumes of water in runoff cavities; large volumes of water could cause frost damage, efflorescence, and corrosion.

- If ancillary steel components are not attached in accordance with the best professional practice, there will be a risk of alteration of the metals in contact.

- For coated and greened sheet pile walls, it must be ensured that the part covered remains accessible. Otherwise maintenance would be more complicated.

- Wood can be used as a cladding material on condition that it is sufficiently durable.

More information on the subject can be found in the brochure “Palplanches métalliques - Aménagements écologiques et paysagers des berges”.

Our other solutions

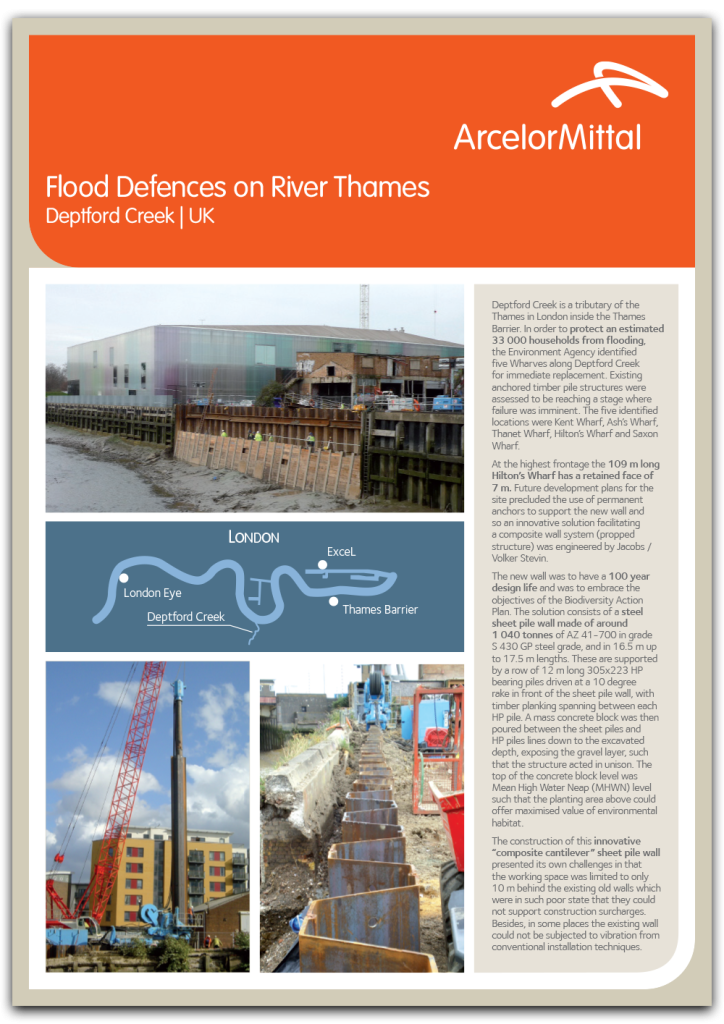

Flood Defences on River Thames

Deptford Creek | UK

In order to protect an estimated 33 000 households from flooding...