AKILA® Sealing System

An environmentally-friendly high performance sealing system developed by ArcelorMittal’s R&D department in Esch-sur-Alzette

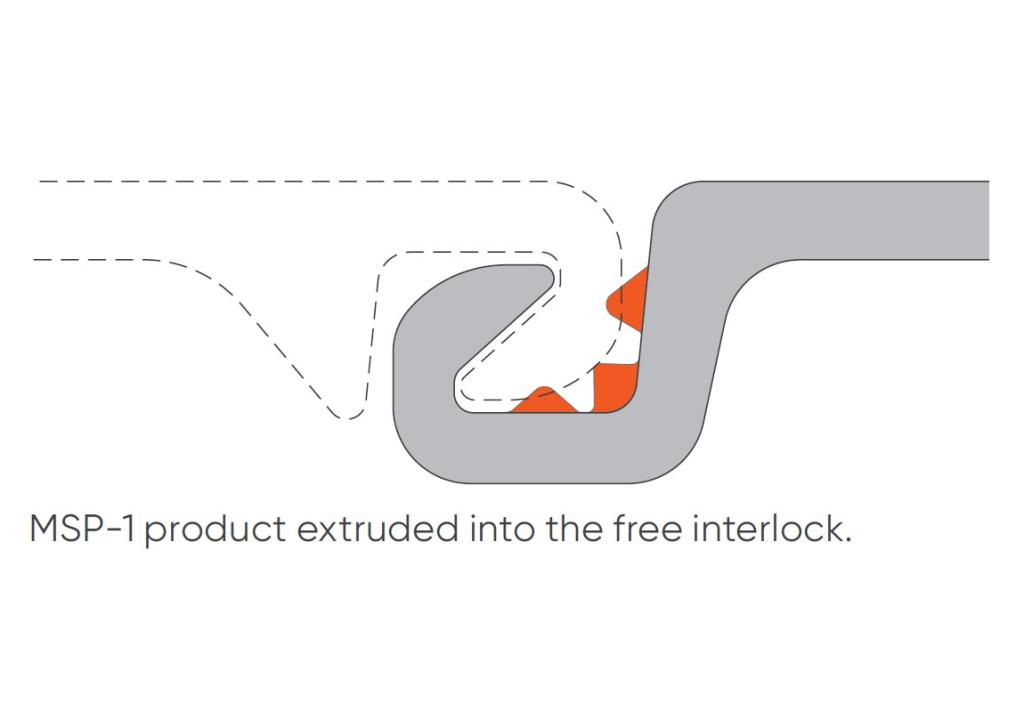

AKILA® is a new environmentally friendly high performance sealing system for ArcelorMittal sheet piles. The system is based on three sealing ‘lips’ – consisting of a product called MSP-1 – mechanically extruded into the interlocks of single sheet piles, or the free interlocks of double sheet piles. In the case of double piles, the intermediary (paired) interlock is sealed with a second product MSP-2.

MSP-1 and MSP-2 both belong to the family of silane modified polymers (also called MS-Polymers), and are single component elastic sealants with a density of 1.41 g/cm3 and 1.48 g/cm3, respectively. They are UV-stable and have an excellent adhesion to primerless steel.

English

English

German

German

French

French

Italian

Italian