Durability

Steel sheet piles are widely used in permanent earth retaining and structural foundation works. In the majority of circumstances, they can be used in an unprotected condition. The degree of corrosion and whether protection is required depends upon the working environment - which can vary even within the same installation.

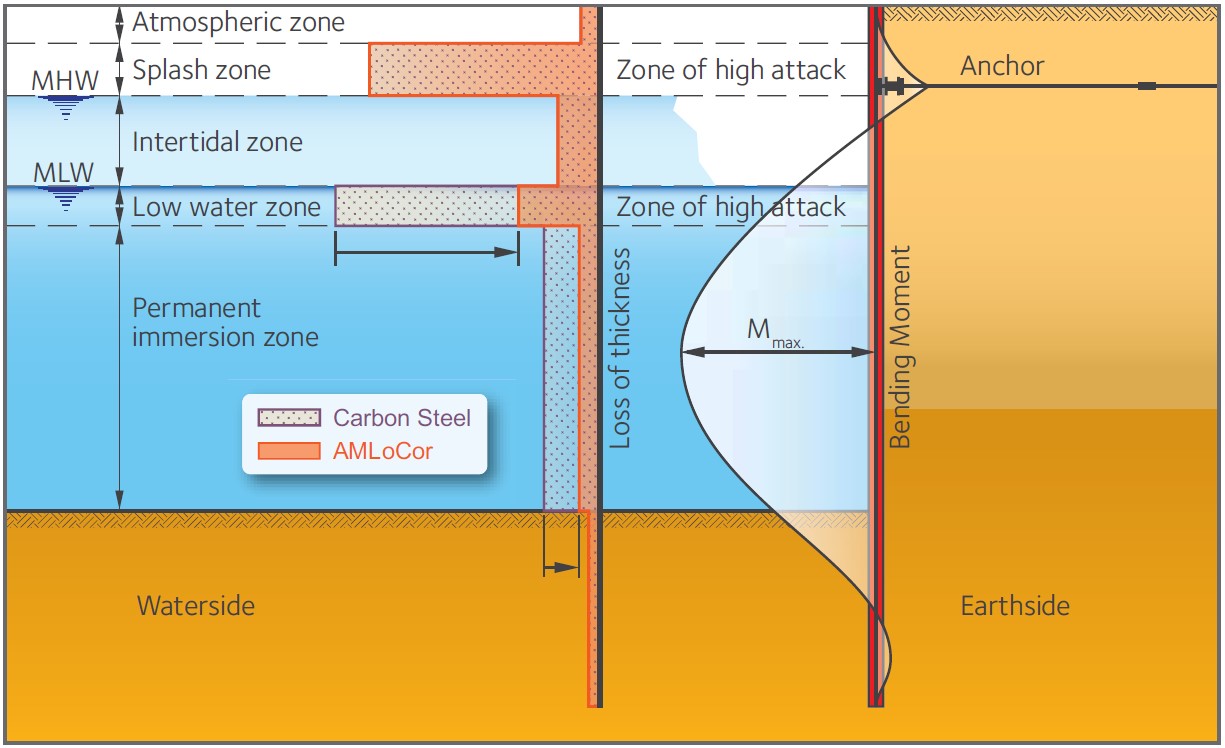

In general, marine environments are the most corrosive. In the few metres of vertical zoning which most structures encompass, parts of the sheet piles are in contact with soil, and exposed to seawater immersion, inter-tidal, splash and marine atmospheric environments.

For most environments, characteristic corrosion rates have been measured (soil, atmospheric, fresh water, marine environment…). The ideal case is to consider corrosion rates measured in adjacent structures, but most often, these data are either not available or not reliable. Typical corrosion rates can be taken from the European standard EN 1993 – Part 5. Note that in specific situations, corrosion due to local conditions may lead to higher corrosion rates, requiring detailed site examinations and data analysis.

In many circumstances steel corrosion rates are low and the use of protective methods is not necessary. However, there are circumstances where corrosion can be more significant, so that measures capable of increasing the service life of a structure should be considered. Protection measures and design considerations include one or a combination of following methods:

- coatings (typically only in zones with high corrosion probability);

- use of a stronger / thicker section, or a higher steel grade, to create a "statical reserve";

- design to avoid the maximum bending moments in zones with high corrosion rates;

- extension of the concrete capping beam below the low-water level;

- use of AMLoCor® steel grade (most efficient in the permanent immersion zone and low water zone);

- use of Mariner steel grade ASTM A690 (splash zone);

- cathodic protection by impressed current or by sacrificial anodes (protects the surface constantly in contact with water).

The adverse effects of abrasion and erosion should be taken into account in the design or in the selection of protective methods, e.g. the use of a special coating.

AMLoCor®

Significantly increases the design life of marine structures

Finally, pitting corrosion, a local phenomenon usually limited to a small portion of the surface of the structure, should be monitored. Measures to prevent retained soil form being washed out through the small holes are easy to implement. Note that generally speaking, pitting corrosion does not affect the overall stability of the retaining wall.

In most cases, the design with a sacrificial thickness of steel is the most cost-effective.

In harsh maritime environments, for the portion below water, cathodic protection can be designed right from the beginning and installed later if monitoring of the structure shows that the corrosion rates after several years are higher than foreseen in the design assumptions.

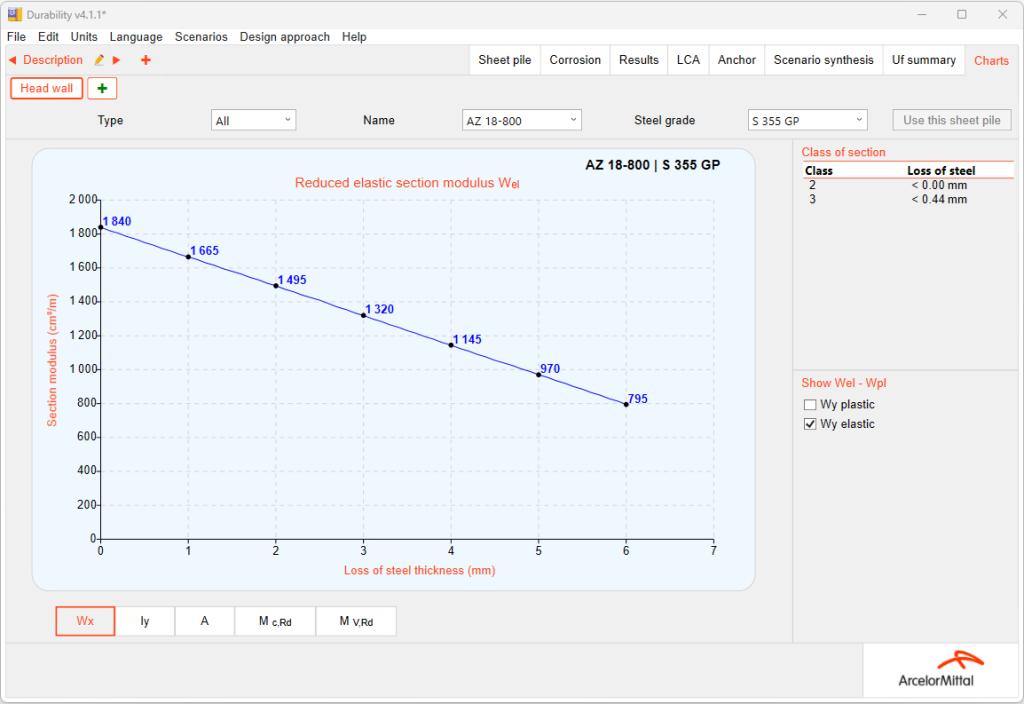

| Excerpt from EN 1993-5: Table 4.1. & 4.2. Loss of steel thickness in (mm) | |||||

| design life (years) | 5 | 25 | 50 | 75 | 100 |

| undisturbed natural soils (sand, clay, …) | 0.00 | 0.30 | 0.60 | 0.90 | 1.20 |

| common fresh water: waterline | 0.15 | 0.55 | 0.90 | 1.15 | 1.40 |

| sea water: permanent immersion & intertidal | 0.25 | 0.90 | 1.75 | 2.60 | 3.50 |

| sea water: splash & low water zone | 0.55 | 1.90 | 3.75 | 5.60 | 7.50 |

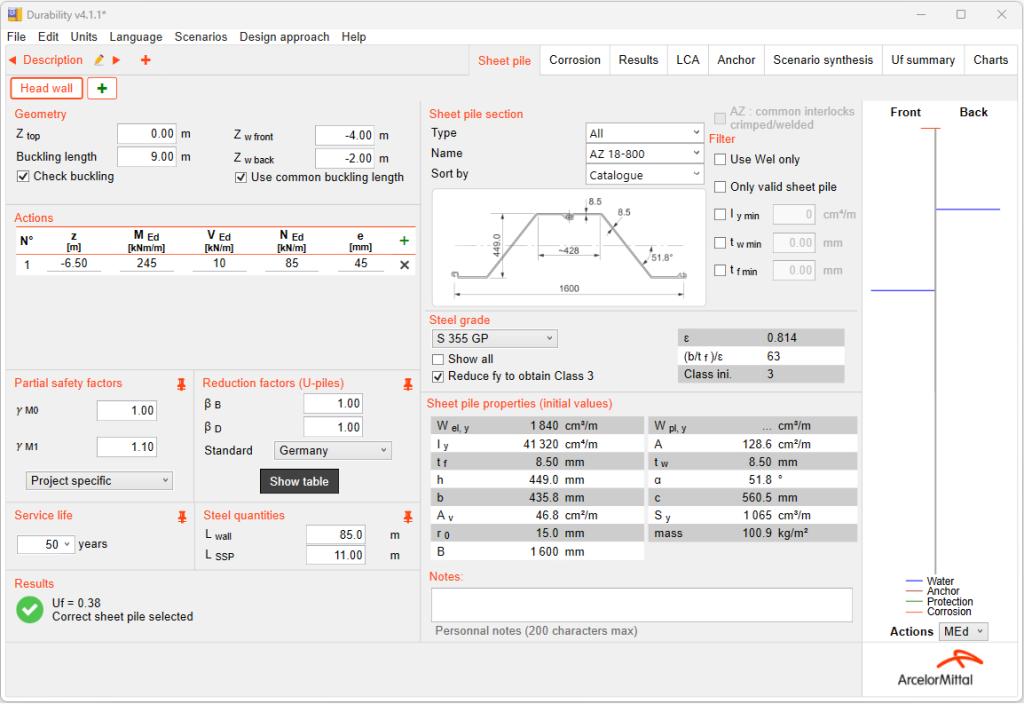

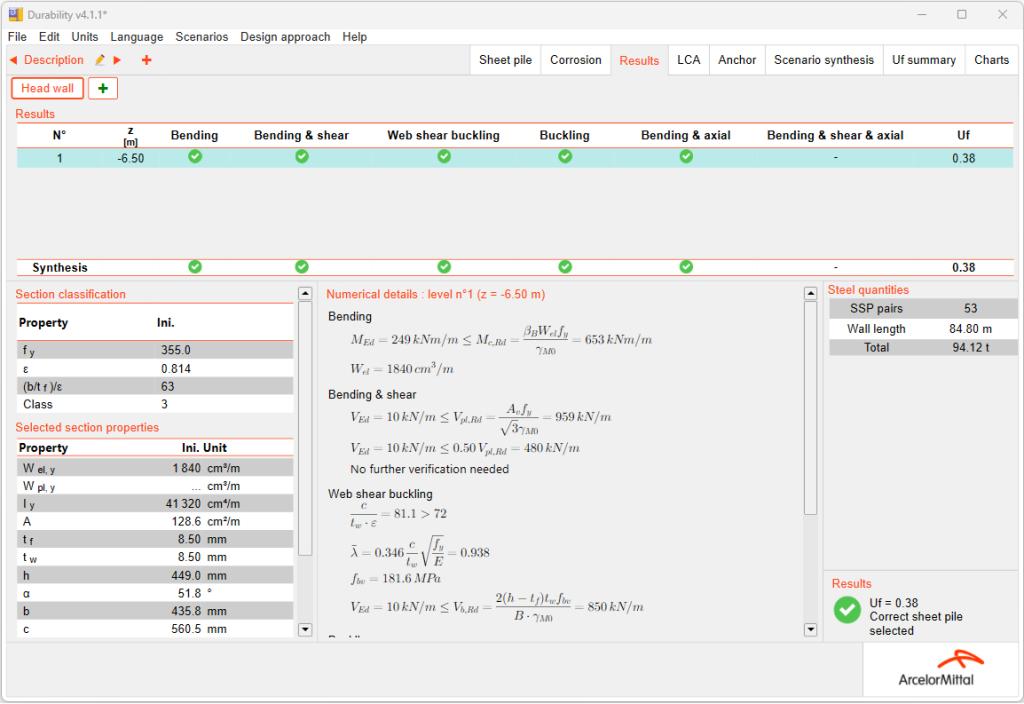

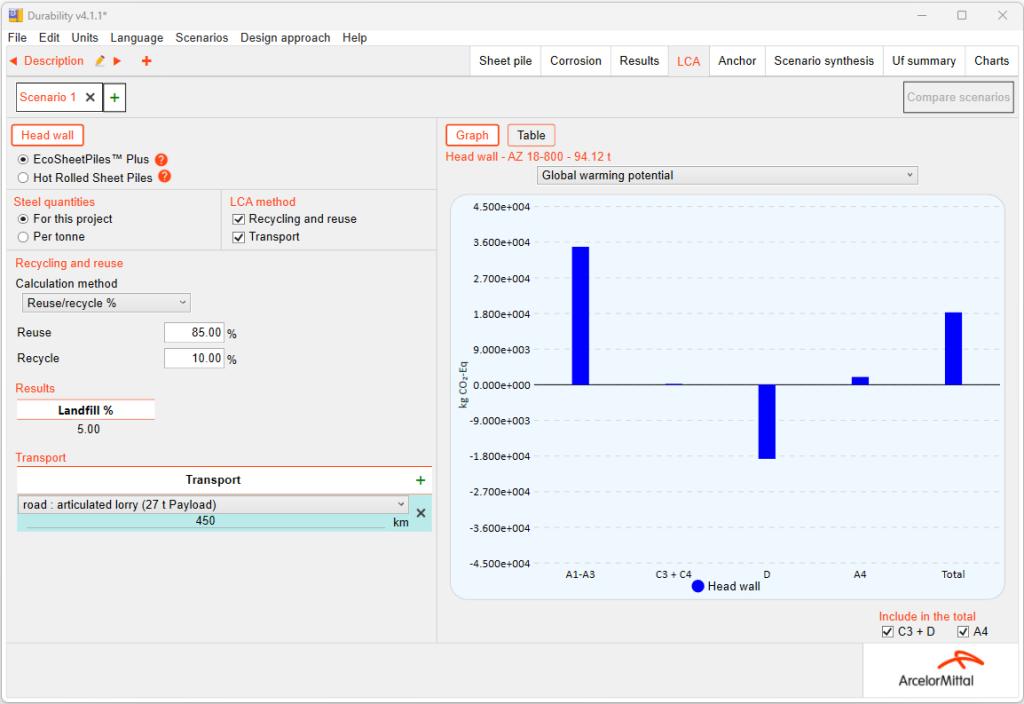

Durability software

Durability is a free, intuitive software that optimizes steel sheet pile designs by assessing durability and service life.

Notes

- Measuring the loss of steel thickness on existing structures

The measuring method as well as the precision of the measuring devices can have a significant influence on the results and their conclusions. ArcelorMittal worked out a quite simple measuring procedure that should allow an adequate analysis of the results of the measurements performed after a few years on the structure. Due to the fact that during the first years the loss of thickness is relatively high, an extrapolation after only a few years of service life could lead to an excessive over-estimation of the corrosion rates if the initial thickness is not known. Therefore, we strongly recommend to perform the first measuring campaign right after the installation of the sheet pile wall (or a couple of months later), and all the successive measures shall be made at different locations. Additionally, the thin layer of corroded steel protects the steel from the corrosion process, so that removing this layer for measuring may have a significant influence on the future corrosion rates. - Corrosion inside the interlocks can be neglected

This statement is based on several structures where the sheet piles were pulled out after the service life and the thickness of the flanges and webs were measured. Very little corrosion was reported inside the interlocks.