Impervious steel sheet pile walls

Ensuring Water Tightness: Rational Analysis and Practical Solutions for Impervious Steel Sheet Pile Walls

Steel sheet piles are completely impervious.

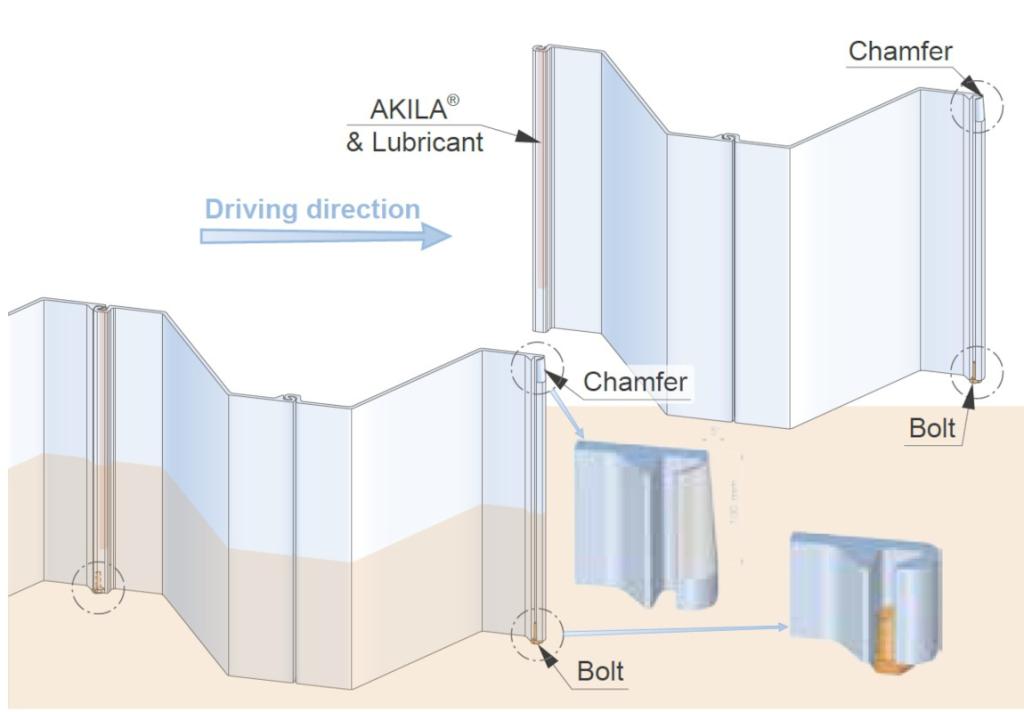

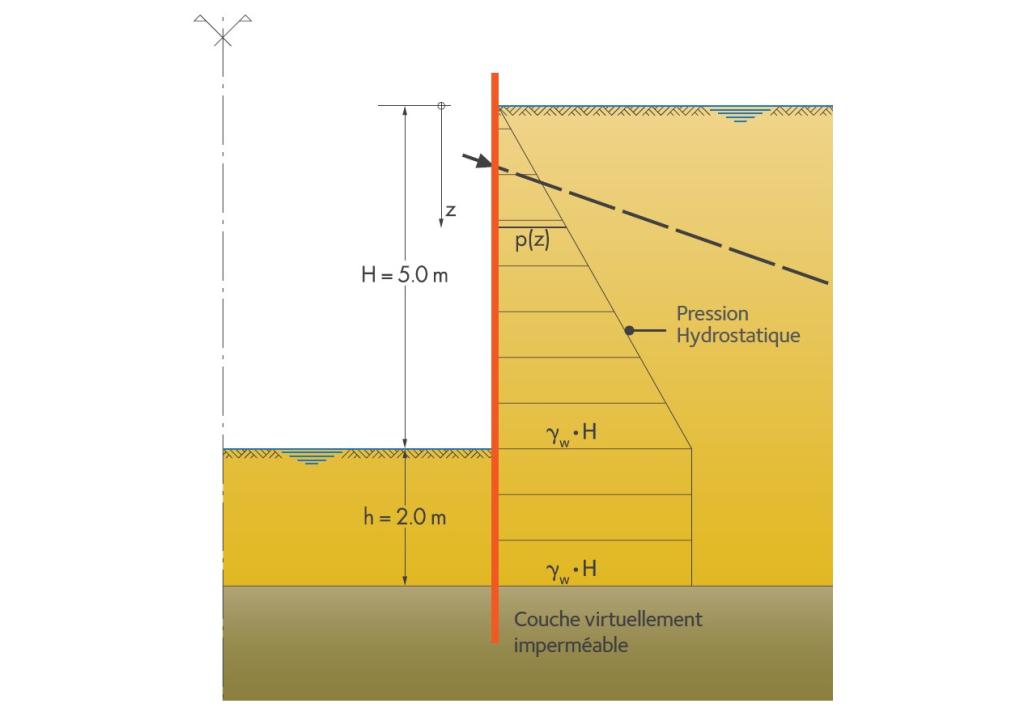

The only possibility of water infiltrating through a sheet pile wall is by penetration through the interlock. Due to its shape, the Larssen interlock naturally provides high seepage resistance.

Sealing systems are therefore not necessary for applications such as temporary retaining walls where moderate rates of seepage are acceptable. If medium to high seepage resistance is required, e.g. cut-off walls for contaminated sites, retaining structures for bridge abutments or tunnels, double sheet piles with sealed or welded joints are recommended.

English

English

German

German

French

French