Pollution remediation project in Annecy | France

Soil pollution remediation

Context

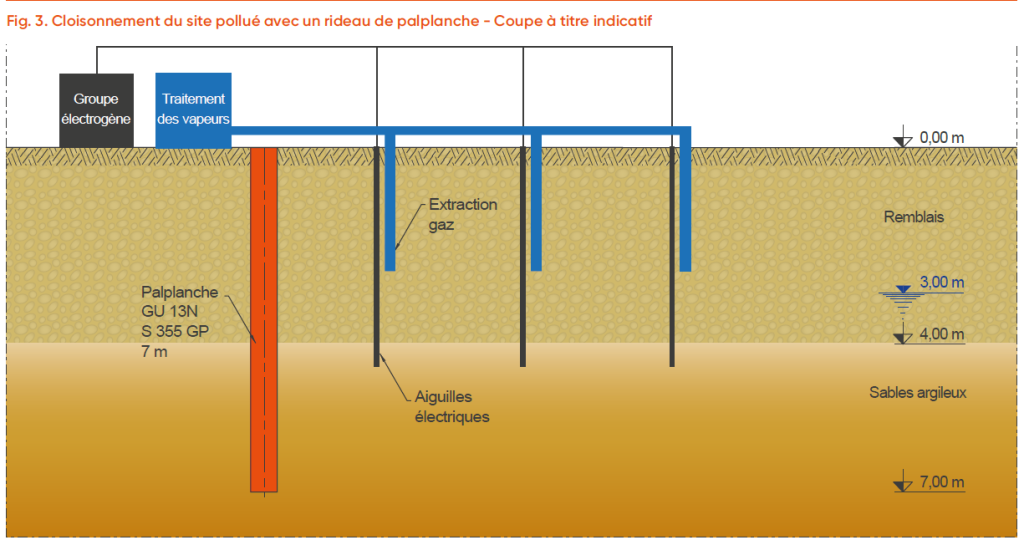

An international producer of metal packaging for the cosmetics industry has cleaned up its former industrial site and subsequently sold it. In Annecy (French Alps) a decontamination project was carried out using a low-carbon approach, made possible by the temporary use of steel sheet piling. In many decontamination projects, soil is excavated and transported to an off-site treatment facility. In this case, however, the project owner opted for an alternative method that avoids moving the soil. As a result, all soil transport—approximately 18,000 m³—which would have impacted traffic in Annecy and generated associated emissions, was avoided. The remediation method chosen for the Annecy project was in-situ thermal desorption (see Figure 3).

During this process, thermal wells were inserted into the contaminated soil, which was then heated to temperatures between 90°C and 550°C, allowing pollutants to be removed through evaporation.

Stale air was collected and treated. This method mainly targets volatile organic compounds (VOCs) but can be extended to other compounds.

Execution

To ensure effective operation and to prevent any impact of the heat treatment (caused by circulation) on the ground water, the treatment area was enclosed by a curtain of watertight sheet piling. DFC Battage installed 183 pairs of uncrimped GU 13N sheet piles, each 7 metres long. A total of 220 metres in plan was installed using a 55-tonne crawler crane with a lattice boom. To avoid vibrations that could damage neighbouring buildings, a variable high-frequency vibrodriver was used—specifically a PTC 23HFV. The top layer of soil generally consisted of brown/grey clayey fill, followed by a layer of grey clayey sand. For this particular project, the in-situ thermal desorption method was used to remove a chemical solvent (Trichloroethylene) from the soil. The entire process (including the installation of sheet piles and other equipment, the soil remediation phase, and the extraction of the sheet piles) took approximately 14 months in total. The same equipment was used for both installation and removal of the sheet piles.

Reuse of sheet piles

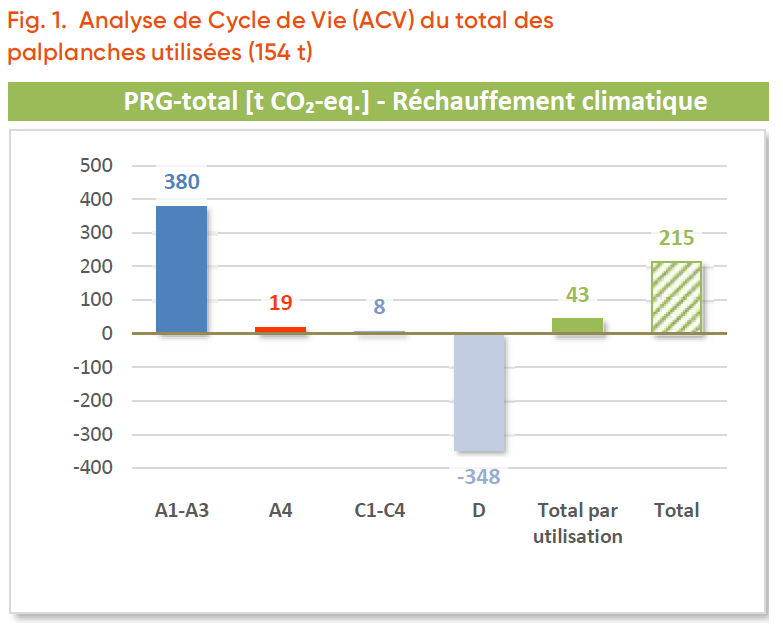

The choice of a sheet-pile solution ensured that the site would remain unsealed after remediation, which is of great importance for future development opportunities. ArcelorMittal rented the GU 13N sheet piles to DFC Battage. After use, the sheet piles were returned to the stock in Messempré (Ardennes, department of Grand Est, France), where they were prepared for reuse on another project. Preparation included cleaning, cutting 20–30 cm from the head, and addressing any other wear and tear that may have hindered reuse. Reusing the sheet piles reduces the overall carbon footprint of the solution.

Download

French

French