Sustainable ports & Life Cycle Assessment

Enhancing Sustainability in Port Operations: Evaluating the Life Cycle

Ports have been faced with quite many challenges in recent years. On the one hand, the sea traffic has steadily increased, modern vessels are getting bigger; on the other hand, our planet is struggling with the greenhouse gas emissions.

Before building a new structure, checking the possibility of extending the service life of existing structures makes sense. This is the best option from an environmental point of view, but most often, old structures need retrofitting. Hence, only an economic and environmental analysis can help the owner to make an informed decision.

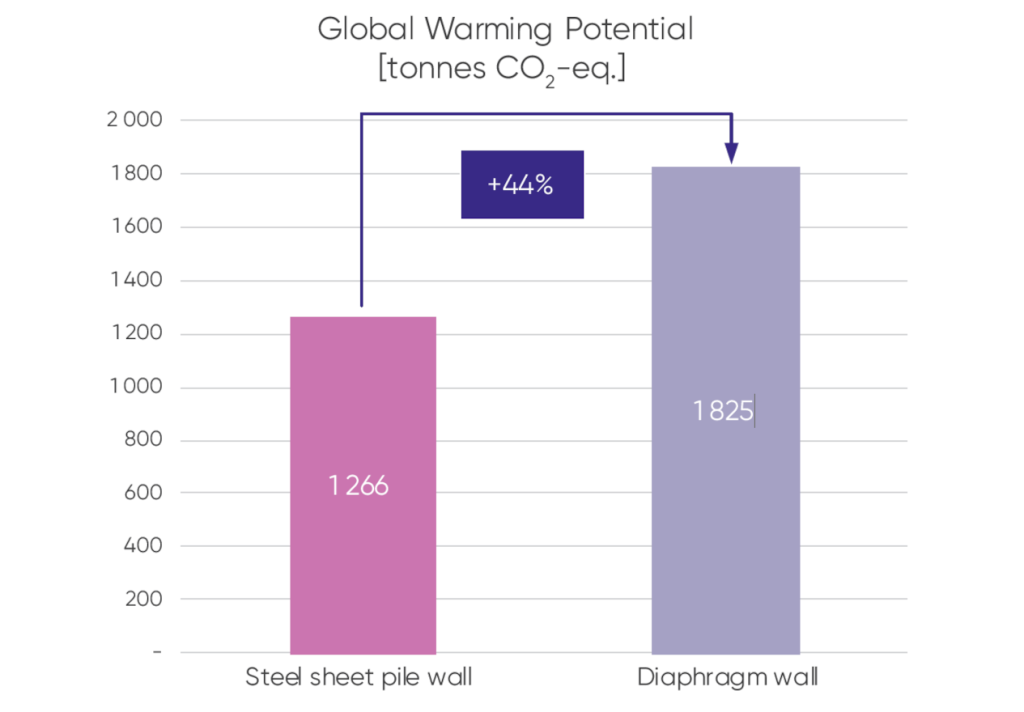

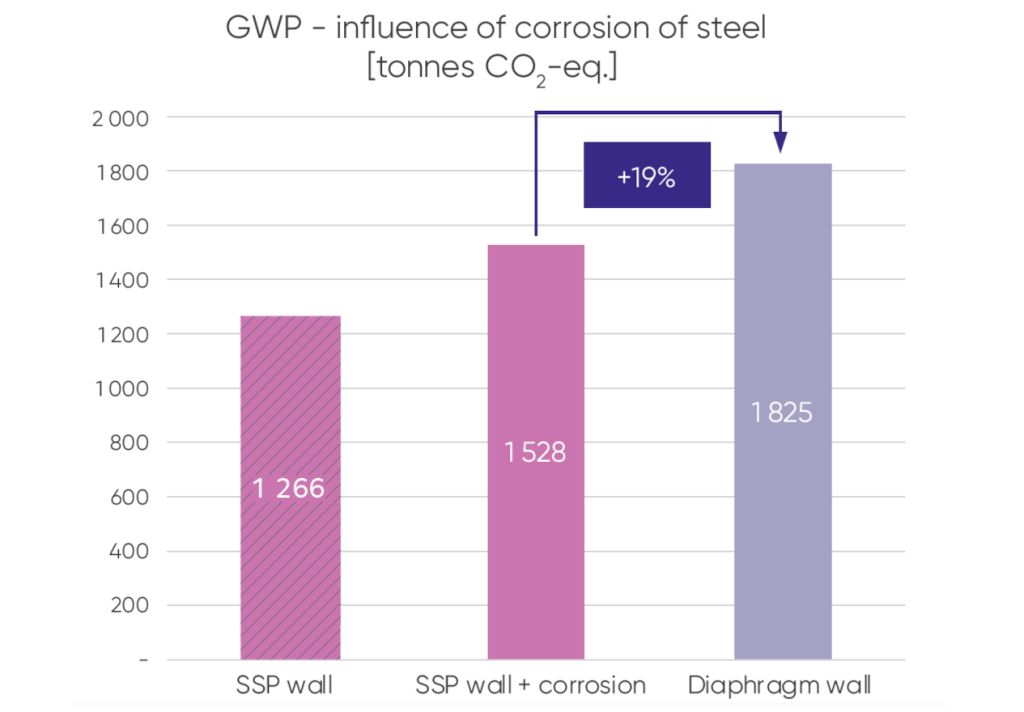

In this case study, the conclusion is that the EcoSheetPile™ steel sheet pile wall has the lowest carbon footprint, the difference being 44 % compared to the diaphragm wall.

Download

English

English

English (USA)

English (USA)

German

German

French

French

Spanish

Spanish