Hazard Protection Solutions

Coastal groynes, Cayeux-sur-Mer, FR | 2015

The project consisted of installing 24 new coastal groins as a continuation of the 80 existing groins, as well as recharging the pebble barrier over a length of around 2.2 km between the South Bitter and the north of the town of Cayeux. The construction of these new groynes on the Cayeux seafront will effectively combat beach erosion, and therefore potential flooding of the town, by stabilising the existing pebble beach.

Download the full case study

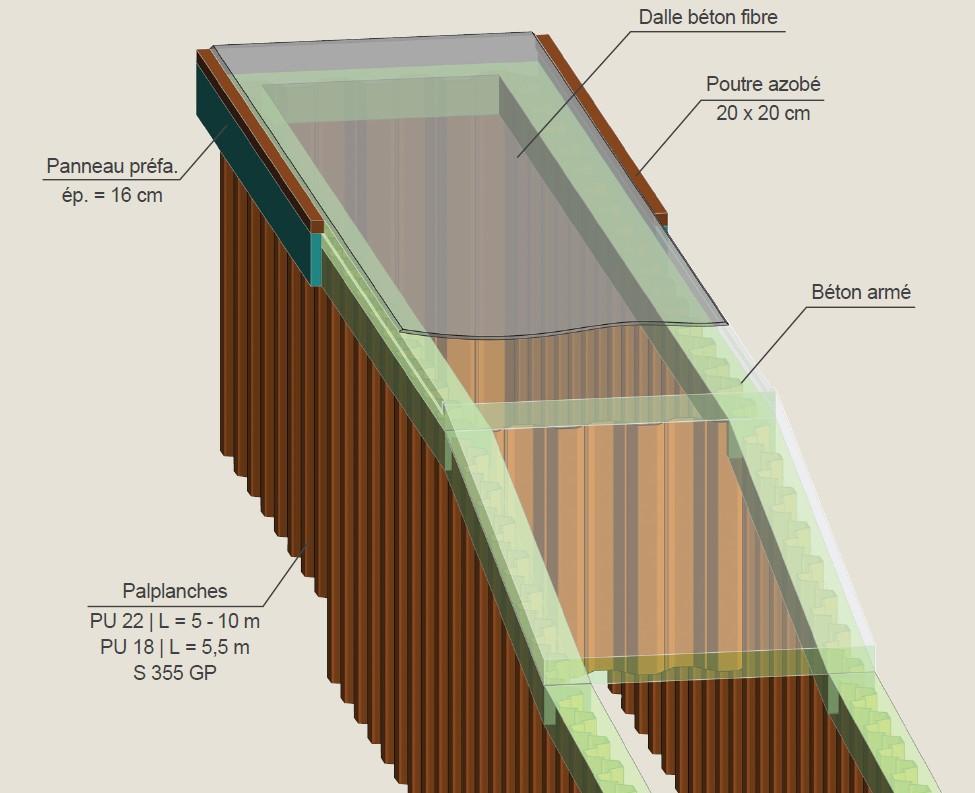

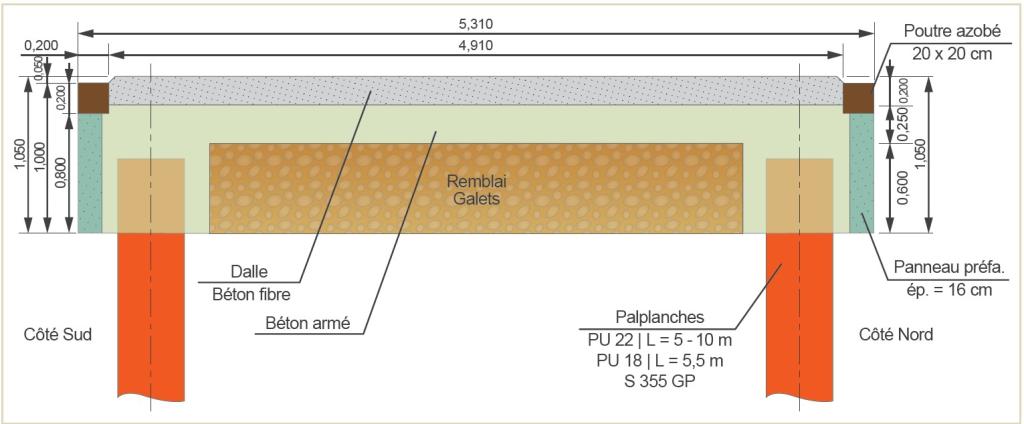

The long-term success of this project will depend on regular maintenance of the site, which includes recharging the beach with pebbles. The groynes were constructed using PU 12, PU 18 and PU 22 steel sheet piles in lengths of 3.8 to 10.0 m, in steel grade S 355 GP. The steel sheet piles are covered with a reinforced concrete beam and exotic wood (Azobé) edge beams.

The construction work on the new groynes also involved recharging with pebbles before and throughout the works. Nearly 250,000 m3 of pebbles were backfilled. Once each groin had been built, the project owner proceeded to install the pebble backfill required to ensure that the structures held firm. This specific contract was awarded to a local company.

The 24 new groynes are spaced 90 m apart along the entire length of the Cayeux beach, with the last 6 progressively set back towards the back shore. The groynes are 85 to 90 m long and 90 cm wide, with the exception of 3 double groynes, which are 5.16 m wide. One of these double groynes is used as a launching ramp, another provides access for emergency services and pedestrians, and the last one must be more resistant to erosion on its north face.

The single groynes consist of a single sheet pile wall with a crown, while the double groynes consist of two sheet pile walls with a crown.

The sheet piles were driven using an ICE 28RF (Resonance Free) vibro-driver, with an eccentric moment of 0 to 28 kgm and a centrifugal force of 0 to 160 kN. Acoustic monitoring on land and in the water was carried out as soon as the first spur was installed to ensure compliance with the noise limits imposed in the concession contract. This limited the noise level to 85 dB(A) at a distance of 40 m from the vibrating source. If this was not the case, noise reduction measures had to be put in place. As for the driving guide, the elements in contact with the Sheet pile had to be non-metallic.

During their service life, the Sheet piles will be subjected to heavy swells and abrasion by the pebbles. The pre-dimensioning of the steel sheet piles was carried out by the design office SOGREAH (Artelia), and the final dimensioning by the driving company in accordance with current European and French Standards (Eurocode 7, NF P 94-282, etc.), taking into account a reduction in steel thickness of 3.5 mm per face, i.e. 7.0 mm in total, for a service life of 30 years, without any additional surface protection coating system.

The steel sheet piles were delivered in several batches between January and October 2014. It should be noted that the specifications severely restricted work during the 2014 summer season.

The groynes were inaugurated in June 2015, while the entire project was completed and inaugurated as planned in December 2015.

The total cost of the works was €18 million. The project was partly financed by the European ERDF fund.

Note

A groin is a rigid hydraulic structure built on the shore of a sea or river, perpendicular to the coast or to the banks, which serves to slow down the flow of water, and therefore to limit the movement of sediment, which can lead to severe erosion of the coastline and river banks, among other things.