Knife Edge Support

Design of the transfer of vertical loads into a steel sheet pile according to the German National Technical Approval Z-15.6-235 (2021)

Steel sheet piles are commonly used for permanent and temporary structures, such as quay walls and retaining walls on road and rail infrastructures. They are typically subjected to horizontal loads caused by earth and water pressure, with minor vertical loads transferred to the walls. However, in some cases, sheet piles must resist significant vertical loads, such as those caused by cranes on quay walls or traffic on bridge abutments.

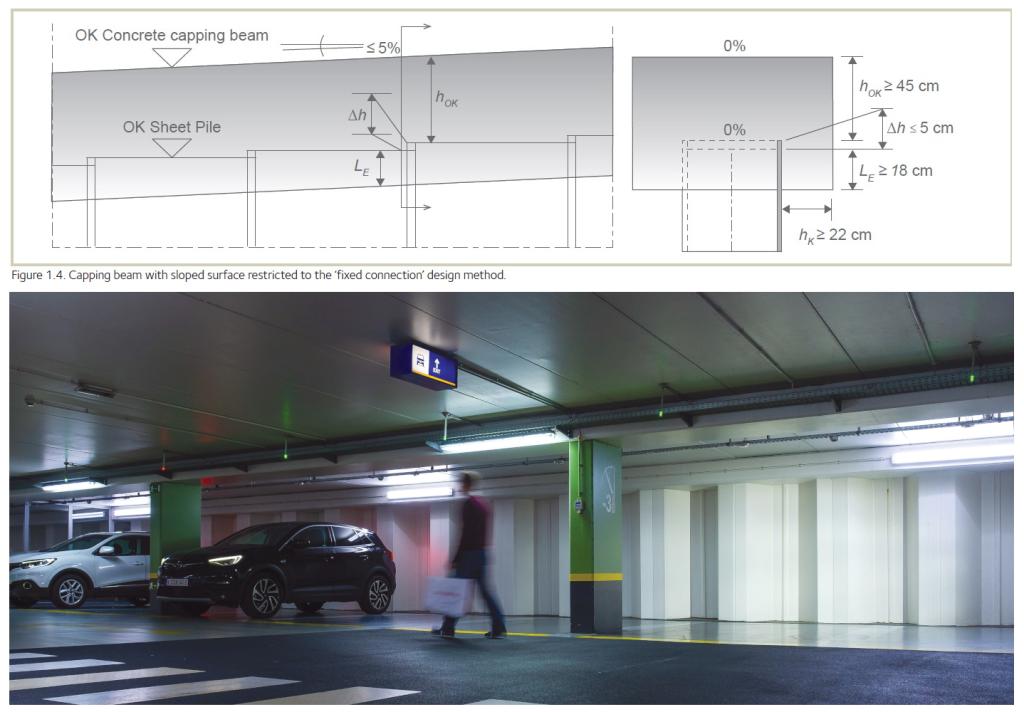

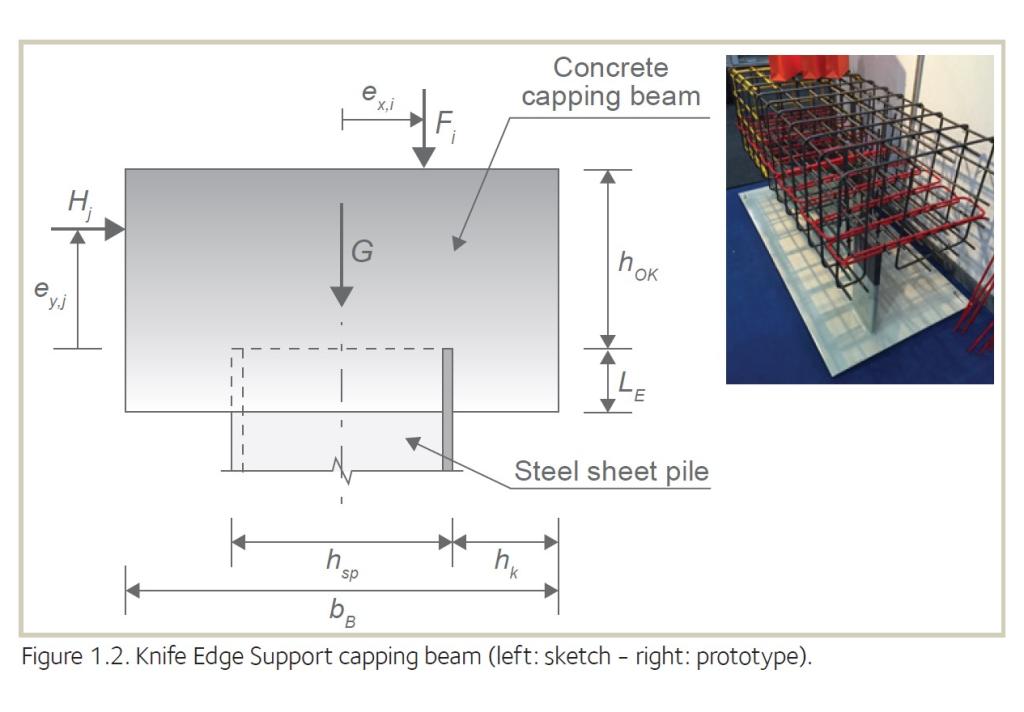

The Knife Edge Support (KES) method offers a cost-effective solution for transmitting horizontal and vertical loads to the ground through a steel sheet pile, without requiring additional welding on-site. This design concept is particularly useful for quay walls, underground car parks, bridge abutments, and locks.

The German authorities have granted National Technical Approval (NTA) to this design, which is based on extensive research and full-scale testing by ArcelorMittal's R&D department and the University of Darmstadt. The tests analyzed load transmission and compared behavior to a standard reinforced capping beam.

English

English

German

German