Port of Piombino, Livorno, IT | 2014

Building the east quay to enhance Industrial and logistic development

The port of Piombino is situated in Livorno, Tuscany, part of central Italy. Since 2012, this port is moving ahead with the realisation of the improvements foreseen in the Port Master Plan, a largescale project for industrial, logistic and port development. Foreseen to be completed in 2020, the sizable infrastructural development of the port area will include new quay walls and the necessary rail and road connections. Thereafter, up to three and a half kilometres of quaysides and around 800 000 square metres of port space will be available, in addition to those currently existing.

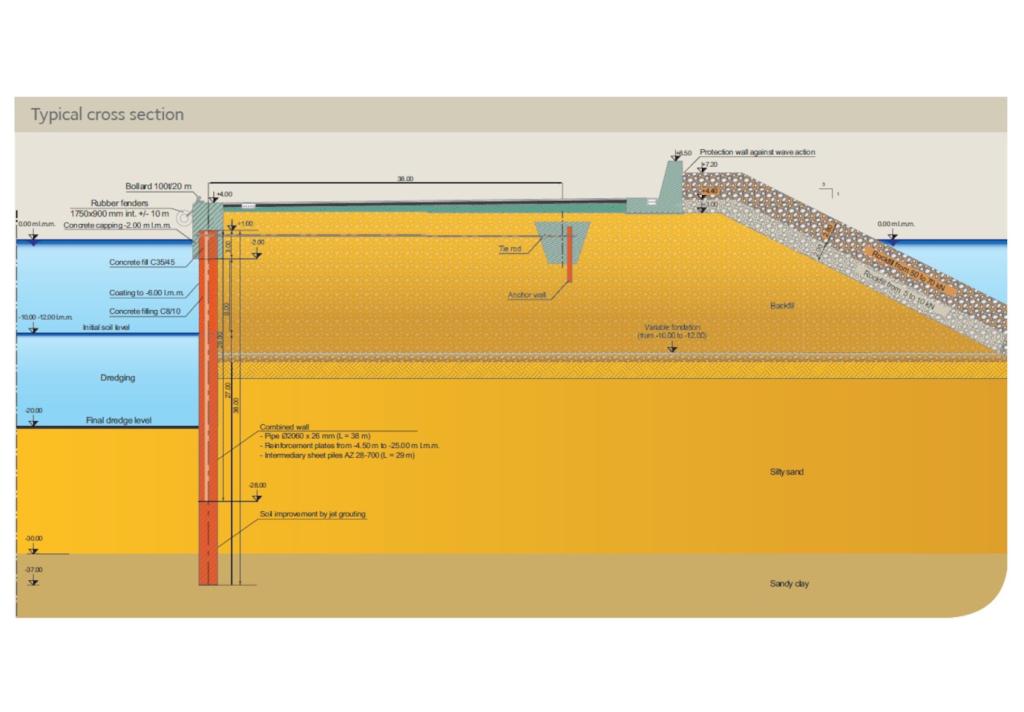

The Port Master Plan includes the construction of a new dock with a 350 m long and 50 m wide East Quay. The dock will be dredged to 20 m below average sea level (l.m.m.).

Download

English

English