Seismic design

Economic benefits of advanced design methods

Advanced design methods yield economical sheet pile solutions in high seismic areas

Commonly used seismic design methods are still considered unsatisfactory in many cases, especially for the steel-based quay wall structures where the application of these design approaches hampers a substantial potential for cost optimisation.

SENER, an international maritime engineering group based in Spain, carried out a study to highlight the main features of advanced design of sheet pile walls in high seismic areas.

This study uses the dynamic design method based on Finite Element Modelling (FEM) and considering real acceleration-time history as seismic input.

Seismic Design Brochure

For detailed guidelines on the seismic design of sheet piles using Finite Element Modelling (FEM), including model geometry and hydrodynamic loads, refer to our comprehensive brochure, and feel free to contact our technical experts for assistance.

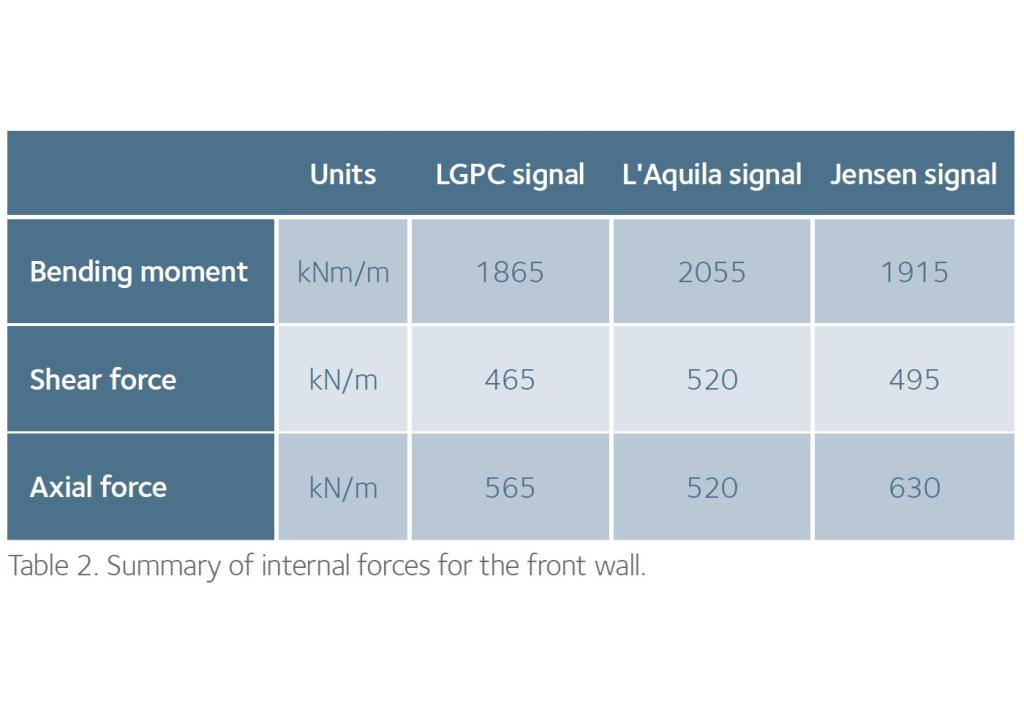

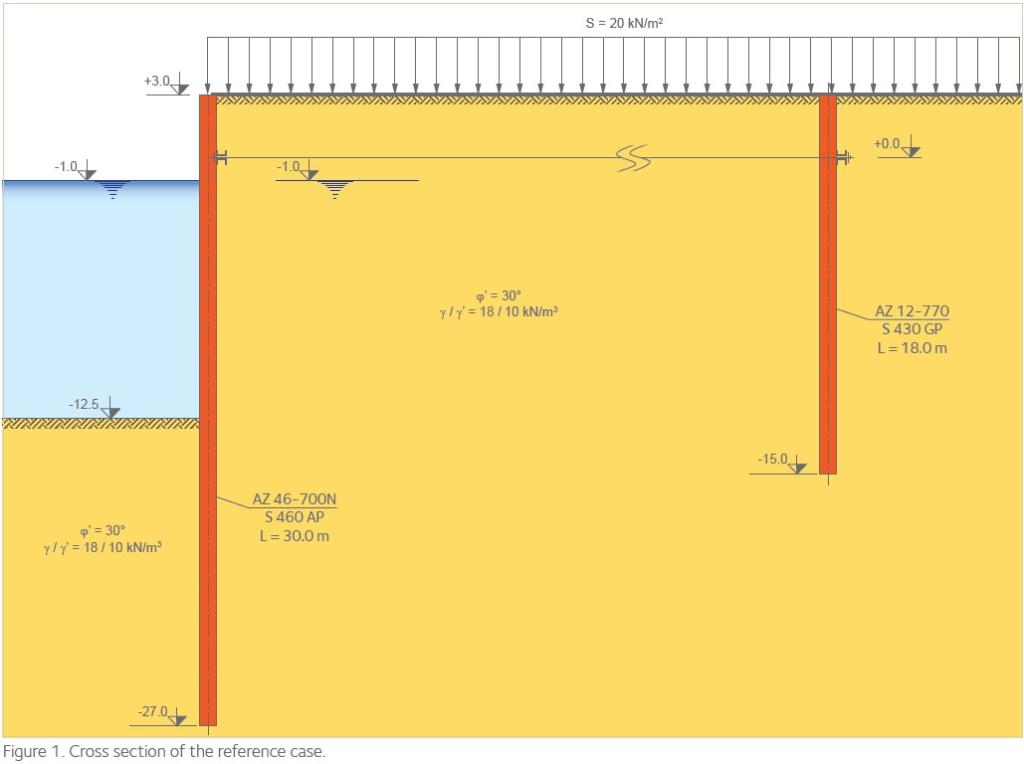

Advanced seismic design methods allow up to 50% cost savings

The first part of the study uses a reference case to highlight the different aspects to be considered in the dynamic design using FEM, it sheds light on the hydrodynamic loads and their impact on the design, using Computational Fluid Dynamics (CFD) models.

There are several soil constitutive models in the literature that can be used in a dynamic FEM calculation. The models that best describe the soil behaviour usually require complex numerical parameters that are not always available to the designer. The Hardening Soil Small Strain (HSSmall) constitutive model is however a good compromise between the complexity of parameters and the accuracy of results.

The HSSmall constitutive model presents the following features:

- Densification;

- Stress-dependent stiffness;

- Soil-Stress history;

- Plastic yielding;

- Dilatancy;

- Strong stiffness variation in the domain of small strains;

- Hysteretic, nonlinear elastic stress-strain relationship (applicable in the range of small strains).

A parametric study covering a wide spectrum of cases

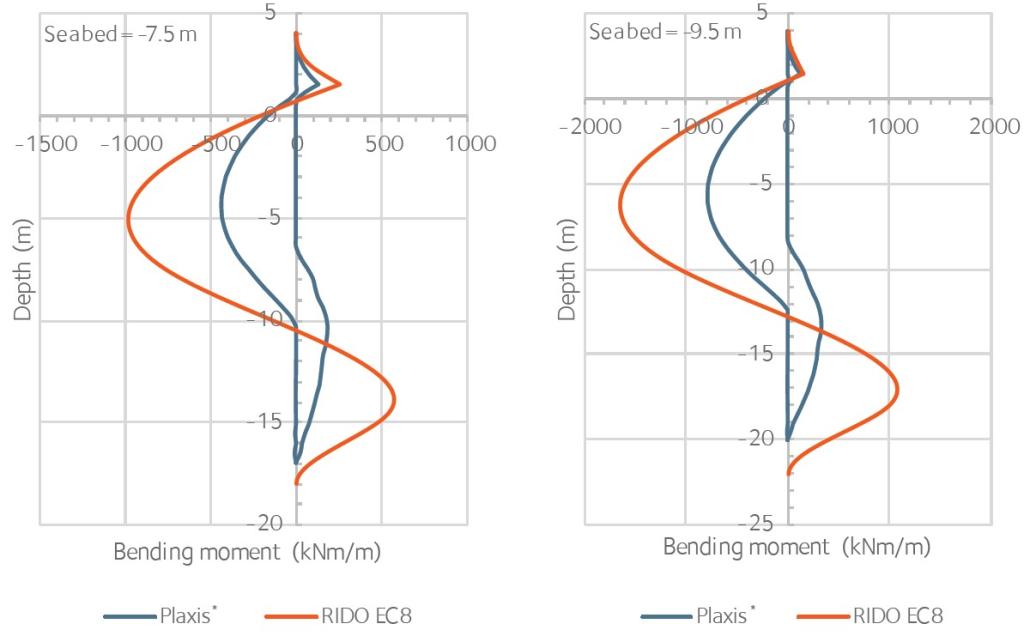

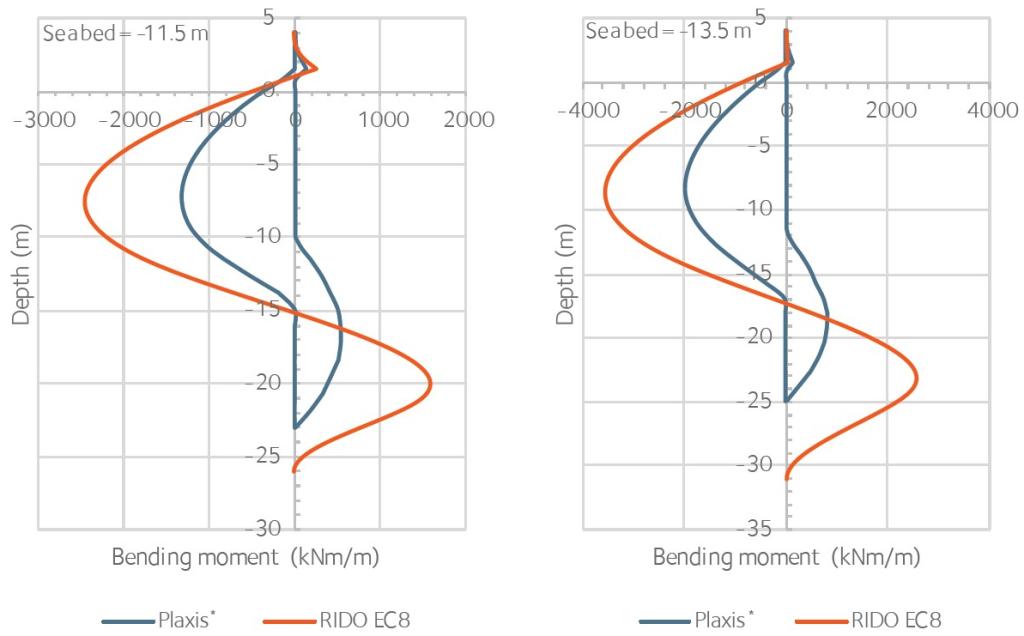

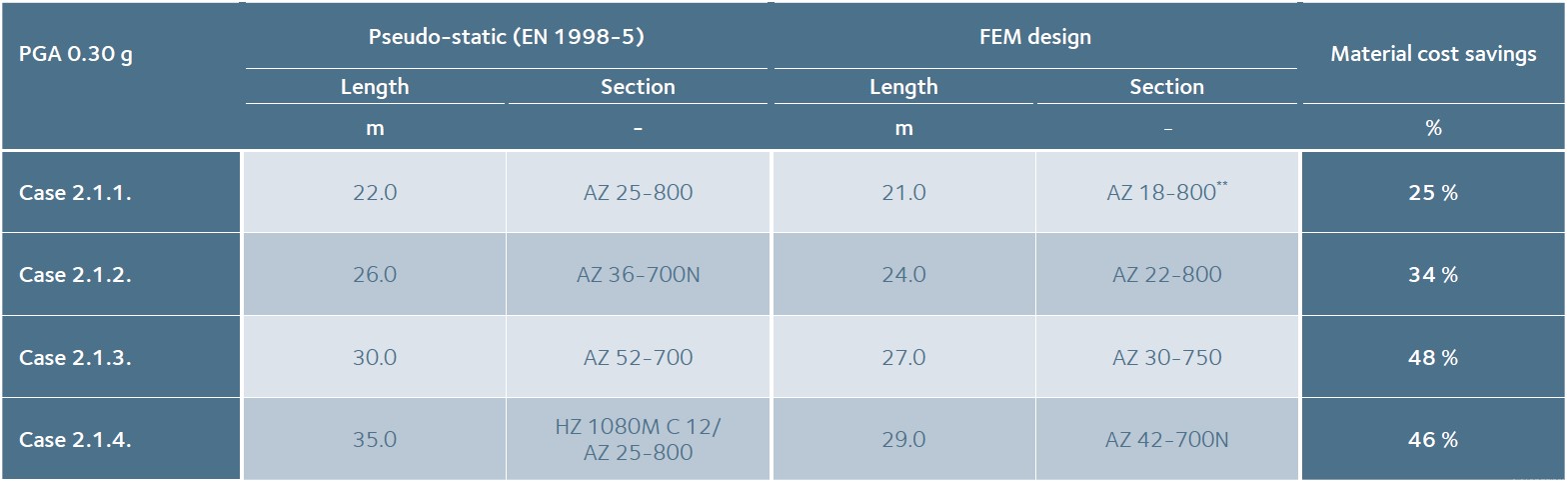

The second part of the study compares the dynamic design method to the traditional pseudo-static method that uses the Mononobe-Okabe formula. The comparison is carried out through a parametric study treating eleven cases. The results are presented, commented and analyzed. Conclusions are finally drawn on the best practices in terms of seismic design of sheet piles.

The study covers 3 cases subdivided to 11 sub-cases.

- Case 1: dense sandy soil, low acceleration level (0.10 g) and two seabed levels

- Case 2: dense sandy soil, two seismic action levels: medium (0.30 g) and high (0.40 g), and four seabed levels

- Case 3: clayey silty soil, high acceleration level (0.50 g) and one seabed level

The pseudo-static design is performed using the elasto-plastic subgrade reaction software RIDO. The seismic action is considered by modifying the earth pressure coefficients Ka and Kp based on the well-known Mononobe-Okabe formula. This results in an increase of the active pressure behind the wall and a decrease of the passive pressure in front of the wall.

The dynamic design is carried out using the FEM software Plaxis 2D. The seismic action is considered by means of seismic signals introduced at the bottom of the 2D model.

The signals used were fitted to the spectra from EN 1998-1 and scaled to the respective Peak Ground Acceleration (PGA) of the studied case.

All the cases studied showed substantial optimization potential when using the FEM design. The bending moments in pseudostatic design are 40 % to 126 % higher than the FEM design. When considering the respective sheet pile sections, the resulting material cost savings are up to 28 % for low to moderate earthquakes (0.10 g) and up to 48 % for strong earthquakes (0.30 g-0.40 g).

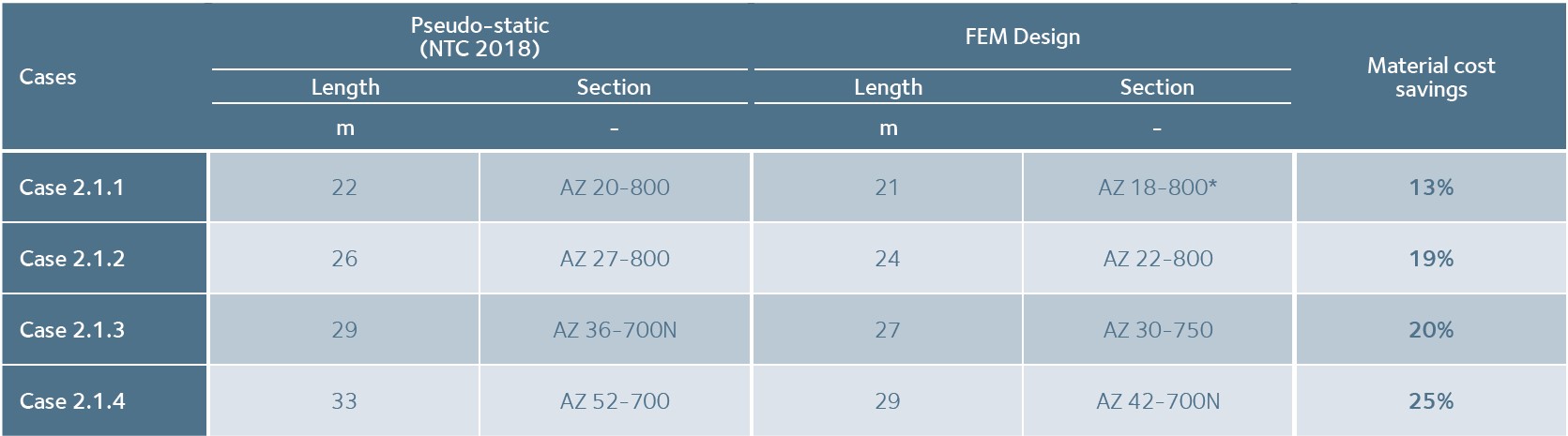

Italian standard NTC 2018

After pinpointing the overestimation that can result from performing pseudo-static calculations using EN 1998-5, the study analyzed what the recent Italian seismic standard NTC 2018 has to offer in this matter.

NTC 2018 follows the same philosophy as EN 1998-5 for pseudo-static calculations but introduces many amendments on the parameters defining the seismic action. The main changes concern the seismic reduction coefficient that accounts for the deformability of the structure and the deformability of the soil among other things. In practice, NTC 2018 allows further reduction of the seismic coefficient for more flexible walls.

SENER carried out the pseudo-static calculations using NTC 2018 as a reference standard for the seismic coefficient. The resulting sheet pile sections were lighter than those obtained with EN 1998-5, and closer to those from dynamic FEM calculations.

These results confirm that the Eurocode EN 1998-5 does not reveal the true potential of sheet piles in seismic areas. This potential can be fully embraced through advanced design methods and more recent standards.