Watertightness

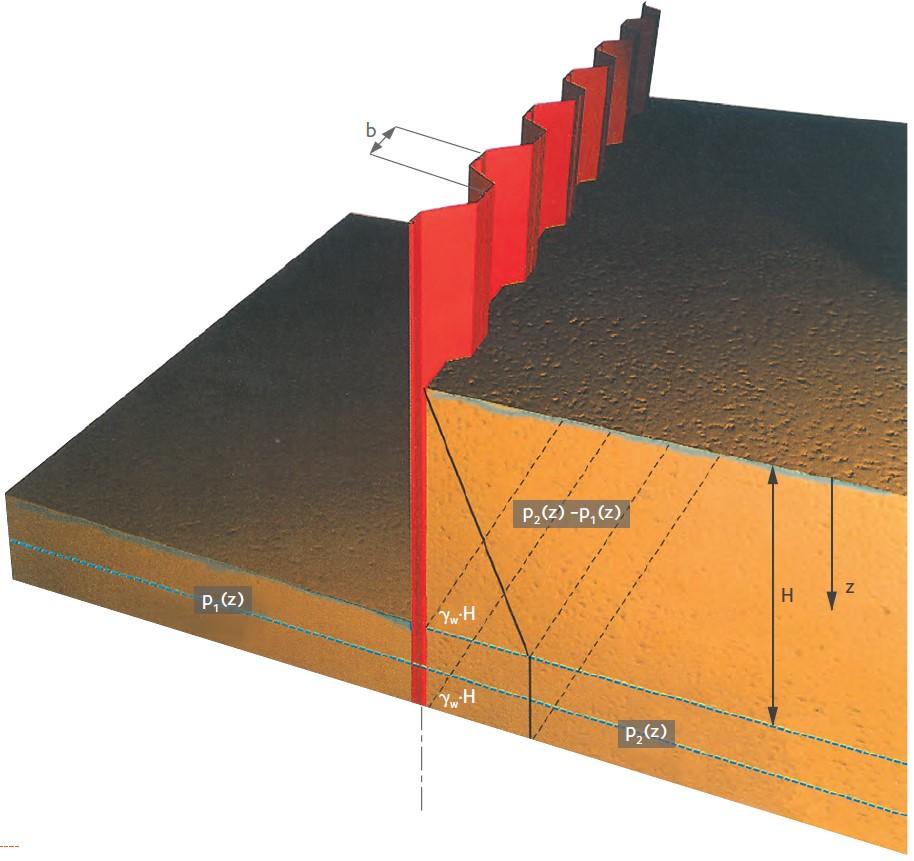

The ability of retaining walls to prevent or restrict the flow of water in the ground is of utmost importance in many civil engineering applications, e.g. in basements, underground car parks, underground reservoirs, temporary cofferdams and containment barriers.

Steel sheet piles are per se impervious, the exception being the interlocks. A sealing system provides a cost-effective solution to control water seepage through the wall, for instance to minimise the risk of settlement of adjacent property, or keeping excavations dry.

The watertightness of ArcelorMittal’s Larssen interlocks invariably improves with time, but a sealant provides a means by which the flow of water can be controlled faster and more reliably.

Impervious steel sheet pile walls

Read about rational analysis and practical solutions for impervious steel sheet pile walls

The flow of water through sealed interlocks can be calculated with a realistic design method which is backed-up by several in-situ full scale tests.

Each construction project is unique because ground conditions, watertightness requirements, installation methods, and so on, vary from site to site. Therefore, the choice of a sealing system must be made carefully considering all the specific constraints and requirements.

The integrity of a sealant will depend upon its suitability regarding the installation and the driving method, as well as the soil and water conditions.

Each construction project is unique because ground conditions, watertightness requirements, installation methods, and so on, vary from site to site. Therefore, the choice of a sealing system must be made carefully considering all the specific constraints and requirements.

The integrity of a sealant will depend upon its suitability regarding the installation and the driving method, as well as the soil and water conditions.

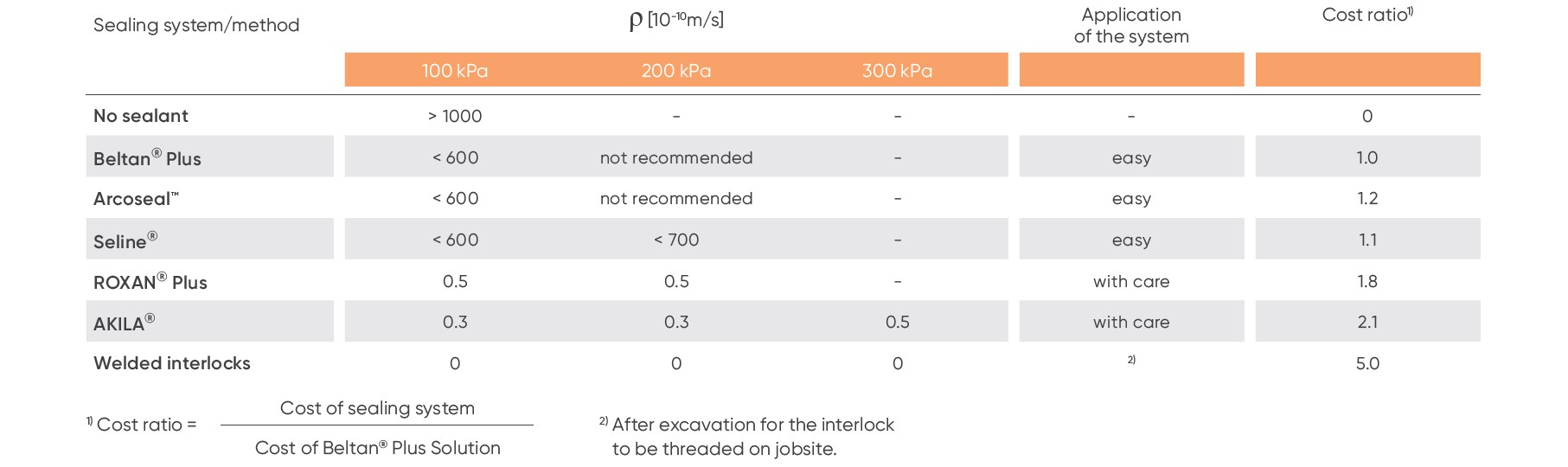

The following sealing systems are used to increase the watertightness of sheet pile walls:

- bituminous filler: Beltan® Plus, maximal water pressure: 100 kPa;

- wax & mineral-oil-based filler: Arcoseal™, maximal water pressure: 100 kPa;

- wood-resin based filler: Seline®, maximal water pressure: 200 kPa;

- water-swelling product: ROXAN® Plus system, maximal water pressure: 200 kPa;

- AKILA® system, maximal water pressure: 300 kPa;

- welding: 100% watertight.

In order to allow the design engineer to use equation Deltares and ArcelorMittal carried out field tests on a large number of filler materials. The results of these tests yield values for ρ. To expose the filler material to extreme site conditions, the sheet piles have been driven in by vibrodriver. Each filler material has been applied in several interlocks. The discharge through each interlock was measured as a function of the applied pressure drop using a special test apparatus, see. The time dependent behaviour is monitored by taking readings at specific time intervals.

The testing programme carried out by Deltares and ArcelorMittal clearly demonstrates that the use of filler products in the interlocks of a SSP wall considerably reduces the seepage rate. Besides, field tests proved that the filler material introduced into the interlocks is confined inside the interlocks even after installation by a vibratory hammer, provided that the specifications of the manufacturer of the product and the specific application procedures elaborated by ArcelorMittal are adhered to.

Note that sealing systems can also prevent soil from clogging the interlocks, which in specific soils can ease the driving.

Double piles to be delivered and/or installed with a sealing system must be crimped before application of the sealing products.

Beltan®, Seline®, Roxan® and Akila® are registered trademarks of ArcelorMittal, Arcoseal™ is a trademark of ArcelorMittal.