Seline®

Sealant

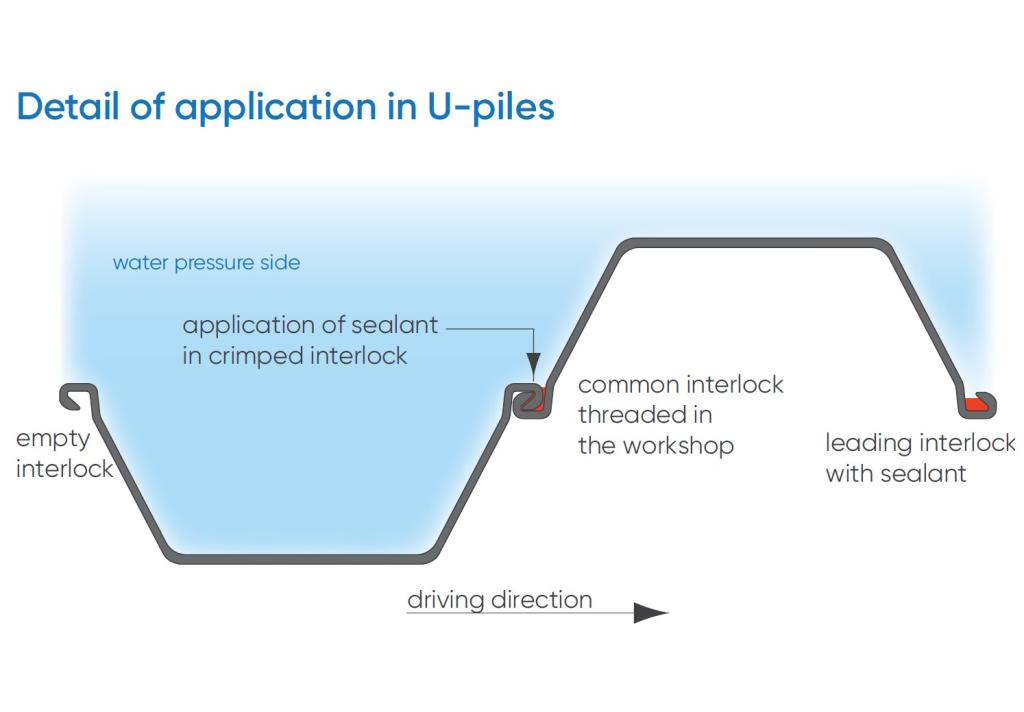

The watertightness of a sheet pile wall essentially depends on the number of interlocks and the interlock geometry. Despite the relatively compact nature of the Larssen interlock, which is a feature of all hot-rolled sheet piles from ArcelorMittal, additional interlock sealants are often used to further reduce water penetration.

Product features

Seline is a completely newly-developed, environmentally friendly sealant for sheet piles from ArcelorMittal. Unlike all other existing sealants, Seline contains a renewable raw material: balsam resin (also known as colophony or gum rosin). This resin is a natural raw material that was used by the ancient Romans and Egyptians. The tree resin is mainly obtained from pine trees by scratching the tree and collecting the balsam that drips out.

Seline is heated in a similar way to bitumen-based sealants and then filled into the sheet pile interlocks. After briefly cooling down, Seline© provides an extremely reliable water seal for sheet pile walls.

Seline is ideally suited for temporary and permanent sheet pile wall structures.

AKILA® Sealing System

An environmentally-friendly high performance sealing system developed by ArcelorMittal’s R&D department in Esch-sur-Alzette

English

English

German

German

French

French

Italian

Italian