Sustainable steel solutions for port infrastructure

João MARTINS

Steel sheet piles have been used in ports for the execution of quay walls for almost 100 years.

They replaced wooden piles due to the lack in the supply of wood by the end of the 19th century.

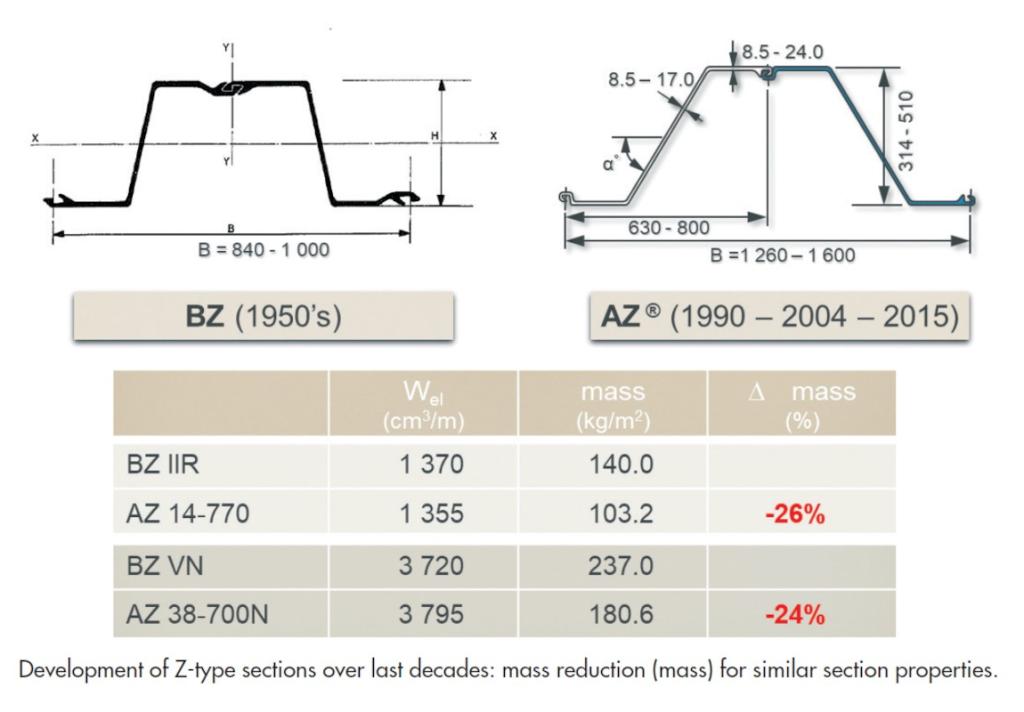

In the meantime, numerous quay walls, jetties and breakwaters around the globe have been built with steel sheet piles. The evolution of the shapes of the profiles combined with the improvement of the steel grades made it possible to design increasingly deeper maritime structures in response to the increase of the size of the vessels.

Research and development contributed to lowering the environmental impact of the steel in several ways. Firstly, by reducing the quantity of steel required to build equivalent structures, and secondly by developing new production routes that recycle steel.

Download

English

English

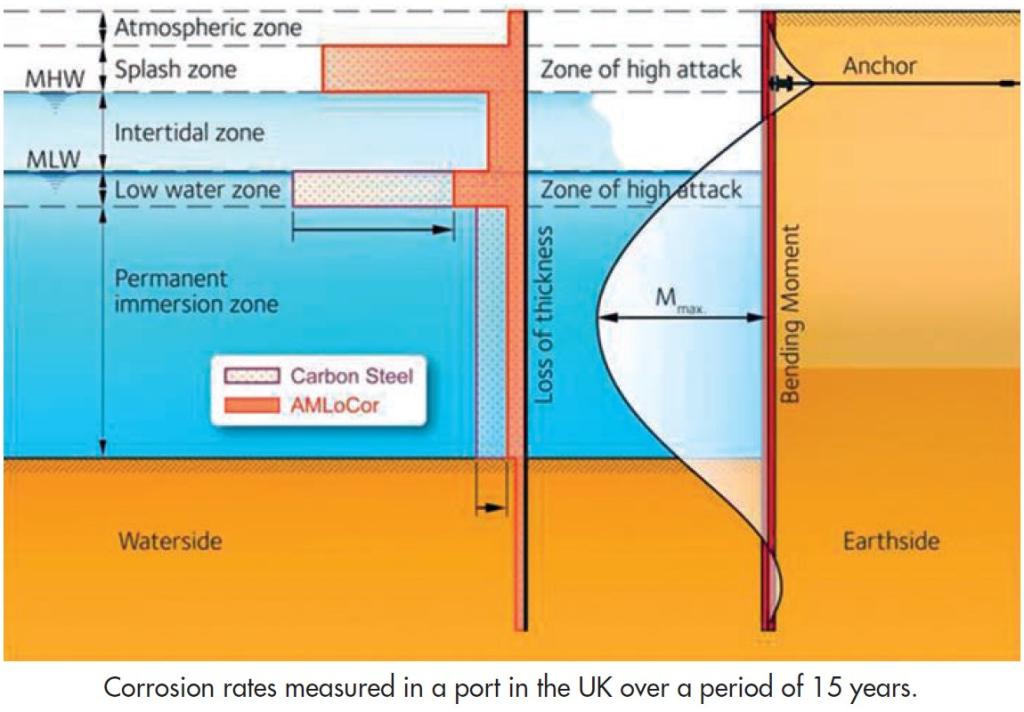

AMLoCor®

Increases Design Life of Marine Structures