AMLoCor® Increases Design Life of Marine Structures

A more durable and long-lasting solution for building marine structures with AMLoCor, ArcelorMittal's low-corrosion steel grad

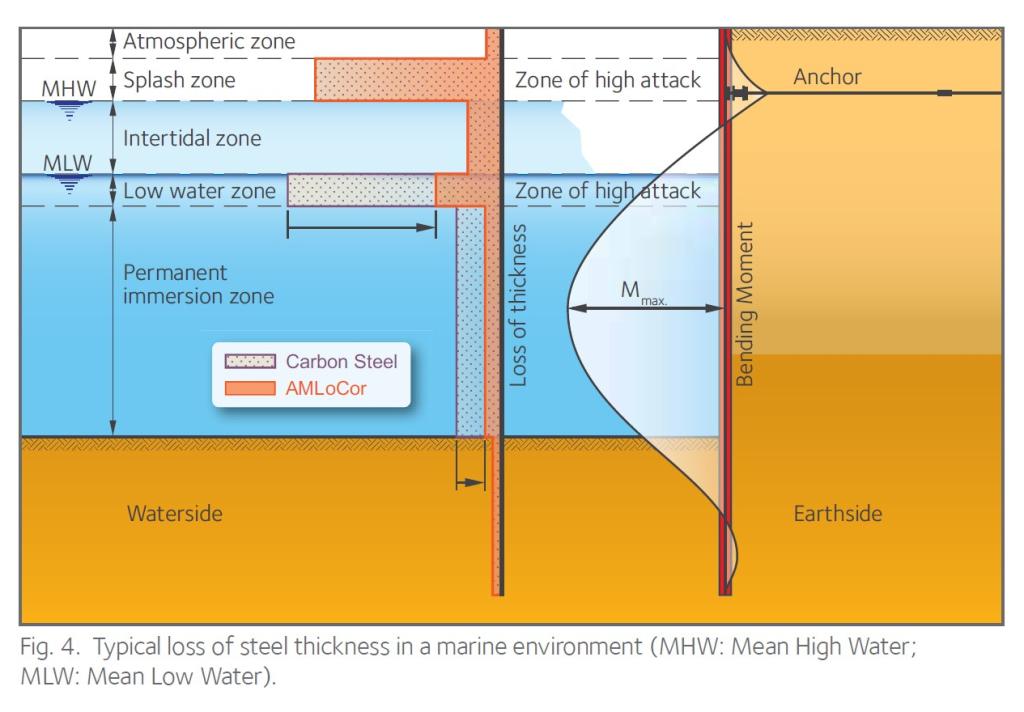

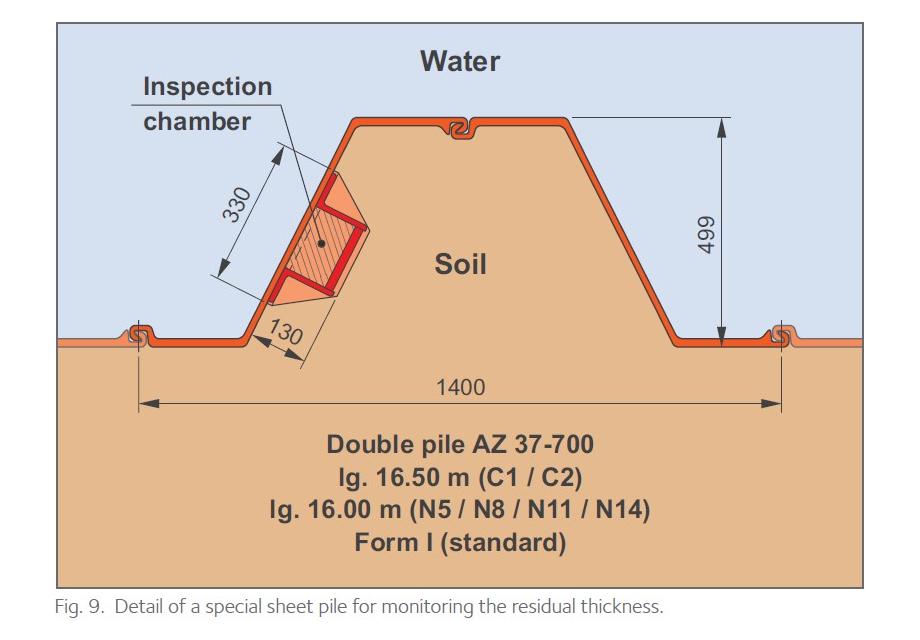

AMLoCor® is ArcelorMittal’s new ‘low corrosion’ steel grade that will undoubtedly revolutionize the design of port structures. A major concern of designers and port authorities is the durability of marine structures like quay walls, breakwaters, jetties. This part contains general information about the new steel grade and the design approach with AMLoCor®.

You can learn more about AMLoCor - Delivery, Properties, and Composition.

English

English

German

German