Hazard protection solutions

The cost of natural hazards

Natural hazards, such as floods, heatwaves, and hurricanes, have inflicted substantial economic losses worldwide. In 2022 alone, global flood-related damages amounted to over $82 billion, accounting for nearly a third of all losses from natural catastrophes that year.

Over the past two decades, extreme weather events have cost the global economy an estimated $2.8 trillion, averaging around $143 billion annually.

These staggering figures underscore the urgent need for comprehensive strategies to prevent or mitigate damage. Public authorities need to invest in resilient infrastructure and early warning systems, while the insurance industry faces increasing strain to cover escalating claims. Collaborative efforts among communities, governments, and private sectors are essential to develop and implement effective solutions, ensuring a safer and more resilient environment.

Steel sheet piles help prevent damage

Steel sheet piles, built as strong and reliable retaining structure, can help safeguard communities from natural disasters. By the end of this module you will be aware of the various applications and advantages of steel sheet piles in the protection against natural hazards.

Watch this video in multiple languages: German / French / Italian / Spanish / Polish

Natural hazards

Flooding, erosion, storms, drought...

Natural hazards result in significant loss of human lives and cause extensive damage to infrastructure, including homes, businesses, and public facilities. Steel sheet piles can be used to mitigate some of them. In the next sections we will see how sheet piles are used, with example case studies.

What are the 4 types of solutions?

Flood protection barriers

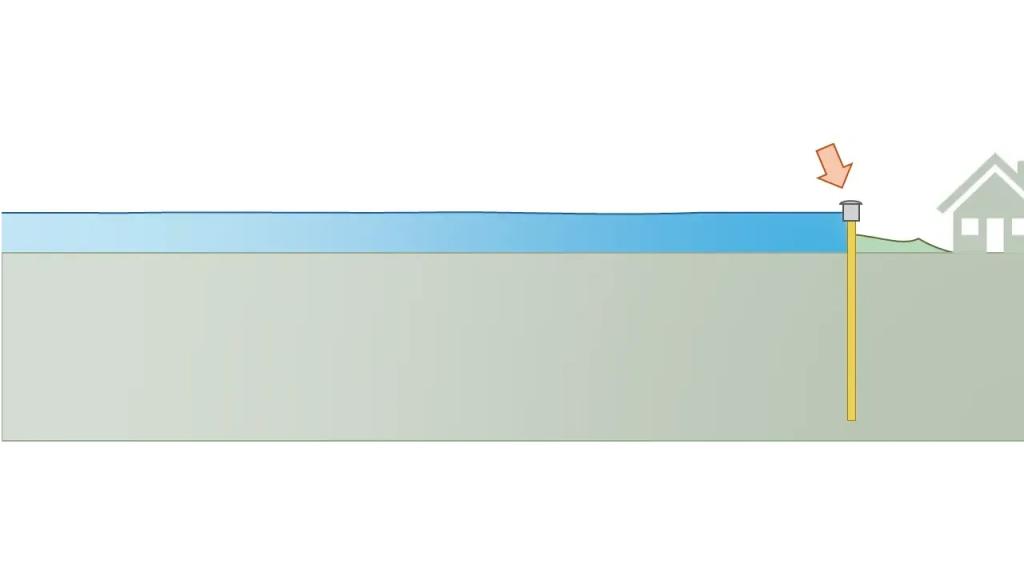

As a flood wall, a sheet pile wall can simply replace a flood embankment, without any reduction in performance. This option is of particular interest in ports or other urban areas where space is limited. The protection can be extended to storm situations (serving as storm surge barriers).

Groynes

Groynes protect the beaches and rivers from erosion due to the wave and current actions. The presence of groynes allows for sediment accumulation, which mitigates the erosion activity.

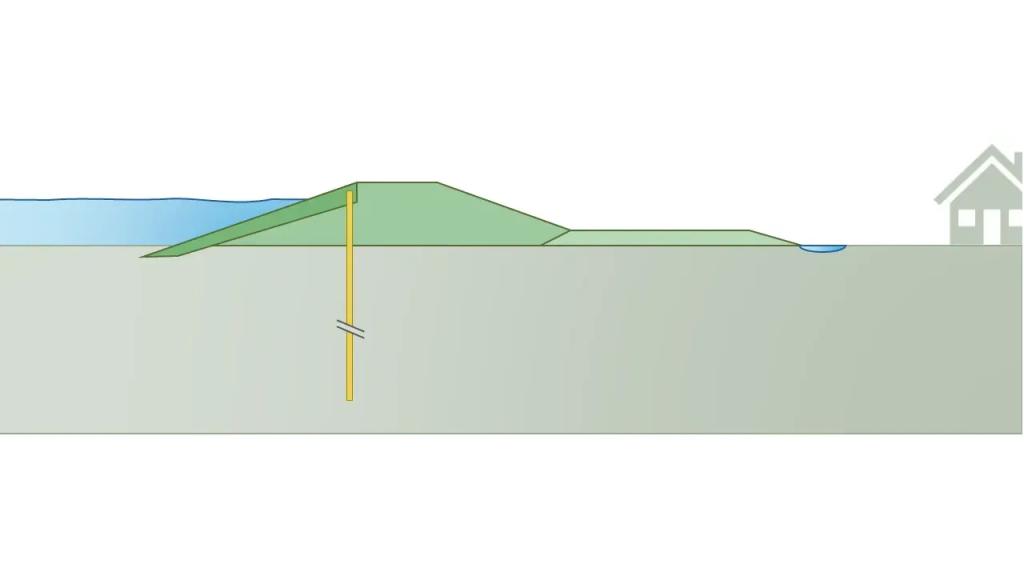

River embankments

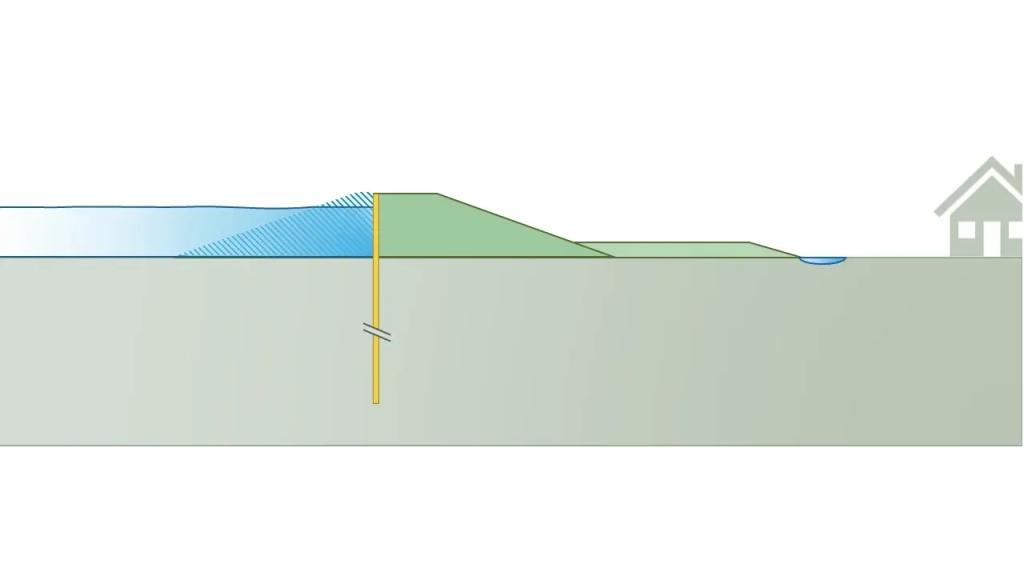

A sheet pile wall makes an embankment watertight and allows modifications to withstand a larger design flood without increasing its footprint. This can be achieved by designing the sheet pile wall to project the requisite height above the crest.

Dyke reinforcements

For stability, sheet pile walls can be designed to mechanically reinforce the dyke. Their flexibility is highly useful, as they accommodate higher external sollicitations while maintaining full resistance.

Overview of solutions for embankments

Did you know that there are multiple ways in which steel sheet piles walls can be used for embankments?

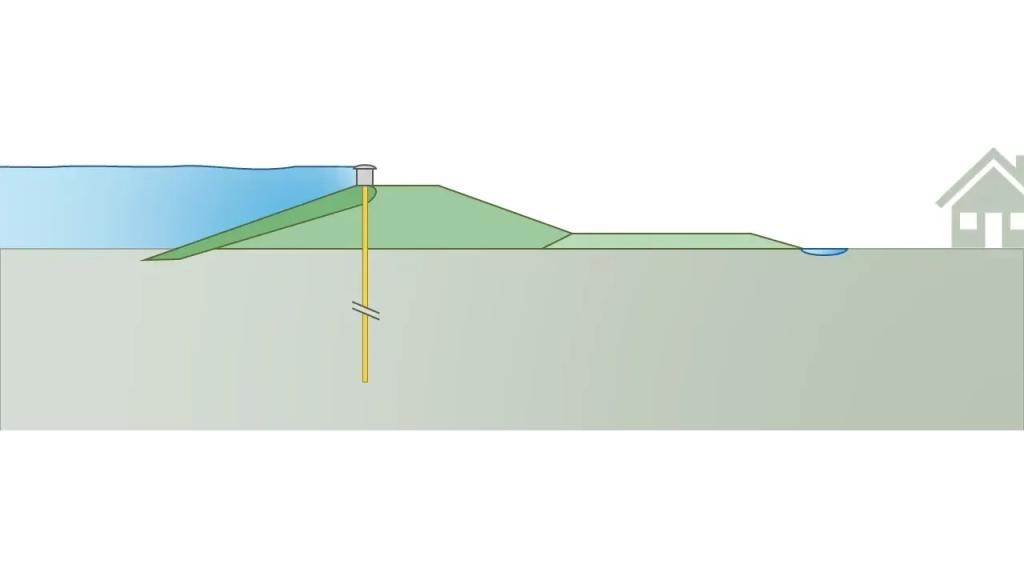

For existing embankments

Increased strength

For existing embankments, steel sheet piles can be installed in front of the existing structure to enhance its capacity without the need for removal, ensuring a minimal footprint and efficient reinforcement.

Protection from hydraulic failure

Steel sheet piles protect embankments from hydraulic failure by forming a strong, impermeable barrier that controls water infiltration and stabilizes soil. They prevent erosion and piping that could be initiated by root trees or burrowing animals. By pushing the hydraulic failure line deeper into the soil, they enhance protection against hydraulic failure.

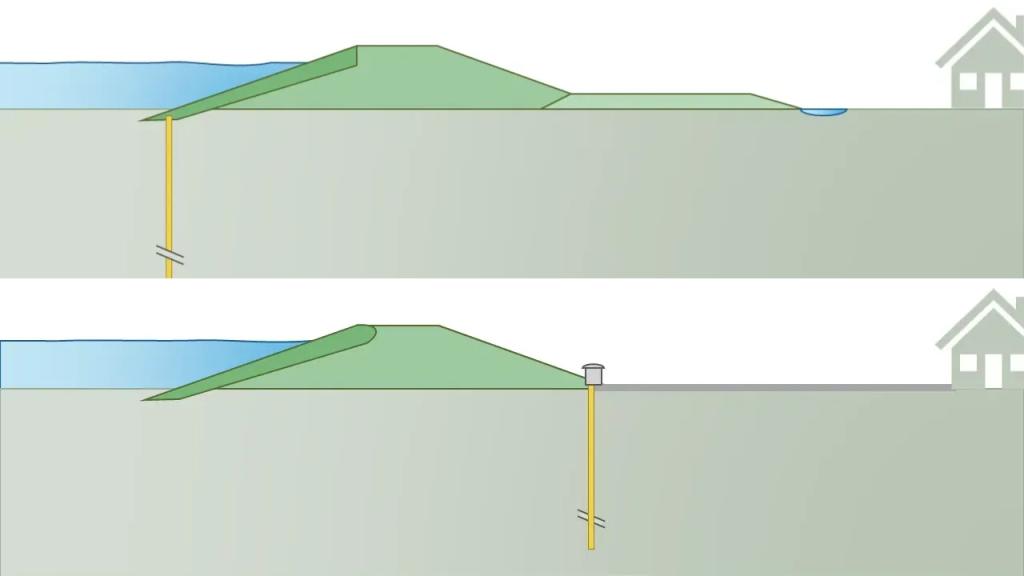

Protection structures for new embankments

Earth stabilization

For new embankments, steel sheet piles provide essential structural support by preventing soil displacement, reinforcing slopes, and controlling water infiltration. They act as a strong retaining barrier, resisting lateral earth pressures and ensuring the embankment remains stable even under heavy loads or varying soil conditions.

Watertightness

Steel sheet piles ensure proper watertightness, either by the presence of soil particles or sealants at the interlock, which is crucial to maintaining the long-term stability and performance of retaining walls.

Support

Steel sheet piles support weakened parts of an embankment (inner shoulder, outer shoulder,...) by increasing its strength.

Steel sheet piles have many advantages that cover project constraints

Installation time

Being prefabricated, sheet piles offer high manufacturing quality, high speed of installation, immediate start of works and short preparation period of the construction site.

Strength and reliability

Steel sheet piles offer high strength and reliability, combining a cost-efficient strength-to-weight ratio, durability and corrosion resistance.

Noise levels

Ability to work in urban areas using low-noise or low-vibration piling equipment > less disturbance during installation.

Durability

Sheet piles have a long design life of 125+ years. Protecting infrastructures for current and future generations!

Available space

Cantilever floodwalls are a suitable technical design choice.

Seismic areas

Adequate to be used in seismic areas thanks to the intrinsic properties of steel (ductility and flexibility - lighter structures have lower inertia).

Environmental standards

Steel sheet piles can be reused several times in temporary applications, thus reducing the environmental impact each time the sheets are re-used. At the end of life, when they cannot be reused, 100% of the steel can be recycled.

Featured projects

Manalapan seawall - USA

The project is reconstruction of seawalls in Manalapan, Florida, following damage caused by Hurricane Sandy in 2012. The original seawalls, built in the 1960s, failed due to overtopping, exposing their support systems.

Replacement involved using stronger, coated steel sheet piles with a longer design life, and incorporating improved designs to enhance stability. The project faced a tight timeframe due to environmental regulations protecting sea turtle nesting grounds. The successful completion involved multiple contractors and significant quantities of steel sheet piling.

Costal groynes in Cayeux sur mer - France

The project aimed to combat the significant erosion of the pebble ridge, which serves as the only barrier against marine incursions for a low-lying area of 4,300 hectares. The project involved the installation of 24 new coastal groynes in addition to the existing 80 groynes and the replenishment of the pebble ridge over a length of approximately 2.2 km. The new groynes were constructed to stabilize the existing pebble ridge and prevent potential submersion of the town.

Flood defence barrier in Boston - UK

Following severe flooding, a £100 million project using steel sheet piling was undertaken to protect over 14,000 properties. The complex design involved a multi-functional barrier incorporating a gate, fish pass, and flood walls, necessitating the use of various steel pile types from ArcelorMittal. Construction challenges, including hard ground conditions, were overcome using specialist equipment and techniques. The project, completed in 2019, significantly enhances flood protection for the town of Boston.