Hazard Protection Solutions

Wall barrier

6,261 tonnes of sheet piles

Flood barrier defence - Boston, UK | 2017

Download the full case study

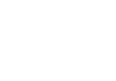

About the Boston Barrier project

Boston Barrier project The Environment Agency, in collaboration with Lincolnshire County Council, Black Sluice Internal Drainage Board and Boston Borough Council developed a scheme to protect the community and more than 14 000 properties - the Boston Barrier. The proposed barrier would need to be multi-functional: it would need a gate to control water flow at the Port of Boston, a fish pass for sea creatures to enter and leave easily, and very importantly, a flood wall to protect the bank on both the right and left side and subsequently the people of the city. Subject to further approval being granted, the barrier would extend to the Haven with further water level controls.

Approved in 2008, the £100 million Boston Barrier project was funded by the Government Flood Defence Grant in Aid, of which £75 million was awarded to the joint venture Bam Nuttall and Mott MacDonald (BMMJV) for the “design and build” contract. They designed for 14 km of steel sheet pile wall barrier, for which nearly 6 000 tonnes of HZ and AZ sheet piles were supplied by ArcelorMittal.

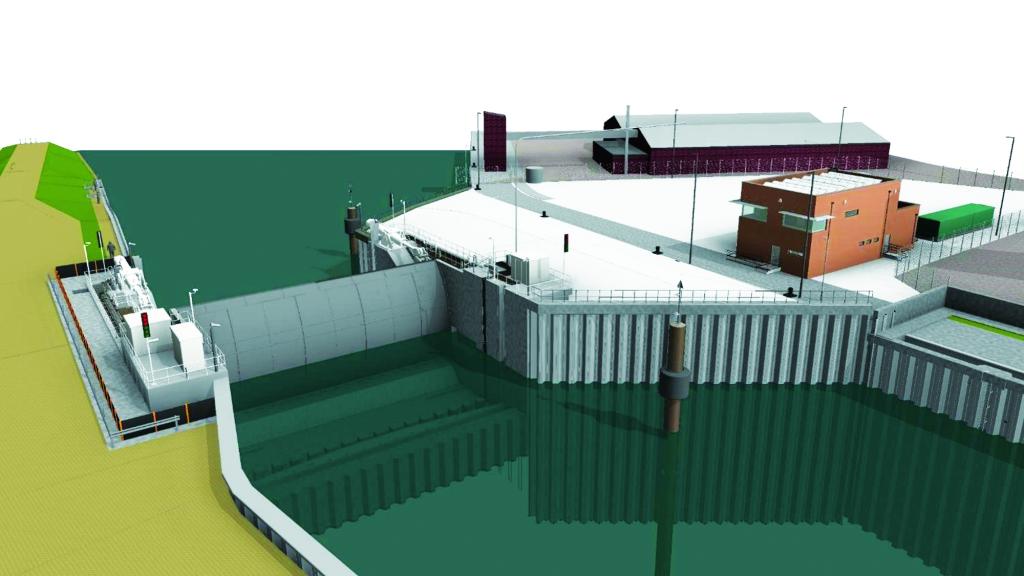

Ground Profile

Upon appointment of the contractors, a full site investigation was initiated to understand the geological profile at Boston. The borehole logs revealed the ground to be Alluvium overlying Glacial Till and Kimmeridge Clay. With the bed level at -3.0 m OD, a conservative design flood level was estimated to be +5.5 m OD.

Steel sheet piles was both the initial and final solution for this barrier project.

Boston Barrier Solution

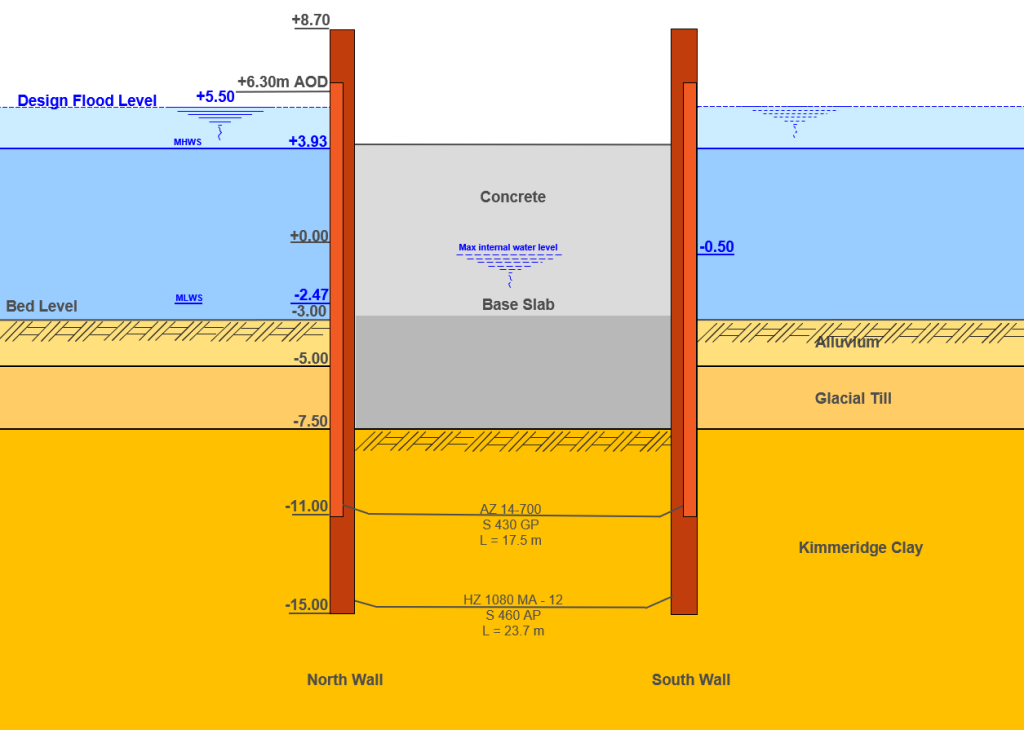

The Boston Barrier gate temporary works design was led by Bam Nuttall design team. This was designed to be a square cofferdam of 35 m length at 15 m deep, weighing 370 tonnes. The cofferdam itself was supported on all four sides, for which BMMJV employed different combinations and arrangements of pile section, anchor walls, corner sections, wailing and so on to support the cofferdam.

North & South of Cofferdam

At the North and South of the Cofferdam wall, the hard driving conditions combined with narrow space became the deciding factor for adopting the effective high-capacity ArcelorMittal HZ®-M system. The benefit of using this type of combined system was not only the outstanding performance of the combined piles but also the guarantee of a continuous wall. The HZ®-M system provided significant cost savings for the project, since the infill piles could be designed in shorter lengths than the H beams. The primary elements HZ 1080M A-12 were designed to be 23.7 m long in steel grade S 460 AP, while the secondary elements AZ 14-700 were only 17.5 m long in steel grade S 430 GP. Although the Z infills were shorter in length as compared to the H beams, they were designed to resist pressure on the active side. The high steel grades adopted for the primary and secondary elements served two purposes:

- to ensure driveability of the piles;

- to increase the bending moment resistance of the structure.

Corners and Junctions

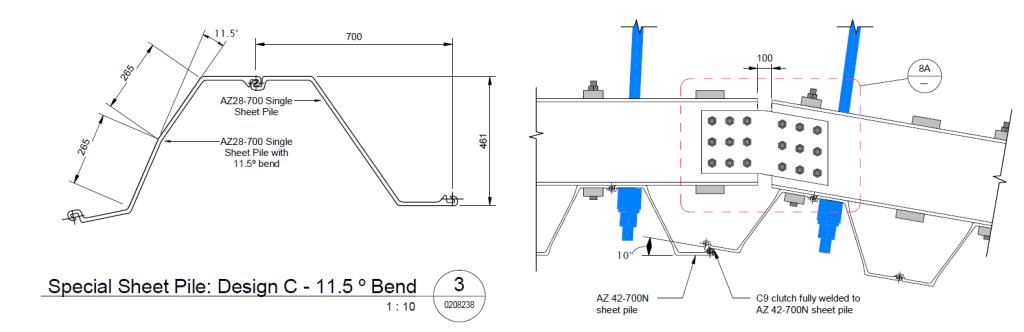

Both upstream and downstream of the cofferdam comprised of double wall systems, which were tied back to limit deflections. The left bank was designed to be strong AZ 42-700N, anchored off-centre; this was bolted with a waling beam to ensure continuity of the wall. Special corner sections were supplied by ArcelorMittal to achieve the numerous changes in direction required for the walls. The C9 was especially useful in this combination because it allowed for tricky deviations such as 10° turns. These were fully welded at the interlock of the AZ 42-700N pile and were driven to depth. At the right bank, special sheet pile sections were fabricated from AZ 28-700 piles, which were bent at 11.5° by one of ArcelorMittal’s subcontractors. The layout of the double wall cofferdams was quite challenging, but with well-planned detailing, this was achieved with utmost success.

Pile installation

To drive the piles to level, a hydraulic crawler crane (CKE 1350) was used. Initially, a 6 tonnes hammer was employed, but given the hard driving conditions at Boston, this was quickly changed to an 8 tonnes capacity hydraulic hammer. This equipment is very effective, especially when difficult driving is expected. To limit noise within the boundary, a 5 m tall temporary noise barrier was deployed to enable works to proceed without disturbing the surrounding area.

Construction Sequence

After installing the wall on the right bank, the South HZ®-M wall was installed, followed by the West wall and the North HZ®-M wall. The cofferdam was then closed off at the North wall with a pair of AZ 14-700 piles. Additional support upstream and downstream of the barrier gate comprised of two double wall cofferdams, which were connected by ties and walings. Within the enclosure, the existing soft alluvium was dredged out and replaced by MOT type 1 material and further compacted to +3.5 m AOD. Finally, the double wall cofferdams were filled with 500 mm of concrete.

Construction Timeline

ArcelorMittal delivered the first piles in November 2017. Following this, construction works began in January 2018 and the barrier was completed in December 2019; an impressive completion timeframe, considering the many challenges that the team faced. The full completion of the project is expected to be in the year 2021.