Hopmarkt underground car park, BE | 2013

The complex project for constructing a three-level car park in a historical city center

Aalst is a Flemish town of 83,000 inhabitants situated 25 km northwest of Brussels. The city recently finished the redevelopment of the Hopmarkt square and surroundings, one of the big projects the municipal council has launched to renovate its historical city center. The project involves the construction of a three level underground car park for 317 cars and the reconstruction of the square with trees and an area for public events with two pavilions housing a bar, a restaurant, a city shop and parking utilities. The construction of the car park, the pavilions and the area for public events was awarded to Interparking NV, who will run the car park in concession for 30 years. Interparking contracted MBG NV for the construction works.

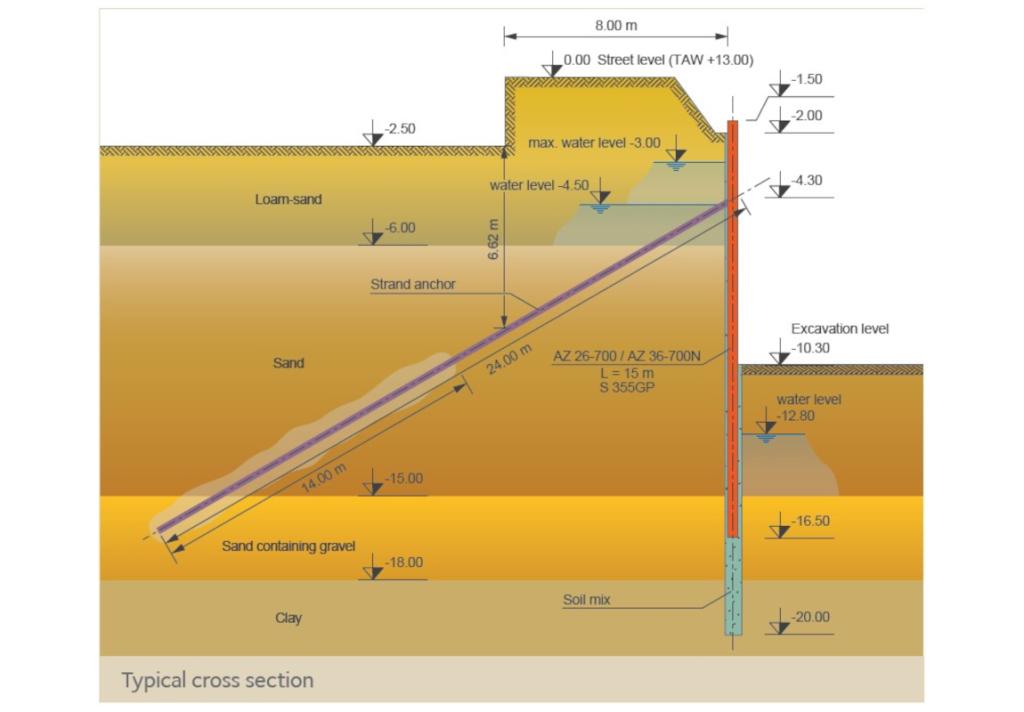

The Hopmarkt square is surrounded by buildings without deep foundations. Due to a settlement risk on a subsoil of peat layers and soft loam, the construction work had to be vibration free (< 2 mm/s) and lowering the water table was limited. The lowest water level allowed outside the building pit was -4.5 m below street level (8.5 m TAW). Therefore, the original design included an execution with slurry walls, reaching into the clay layer up to -20.0 m below street level.

Download

English

English