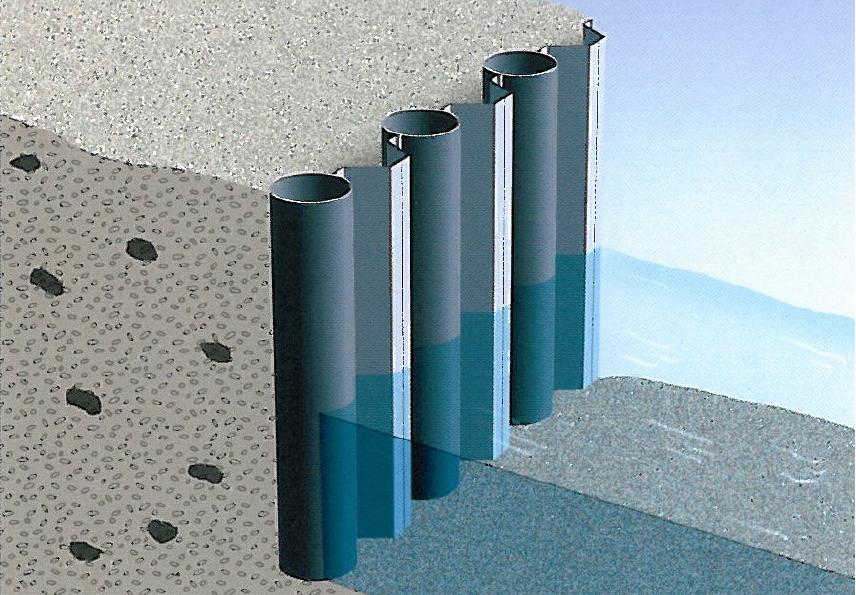

AZ sheet piles in combined walls

Exceptional performance of AZ sheet piles in combined walls

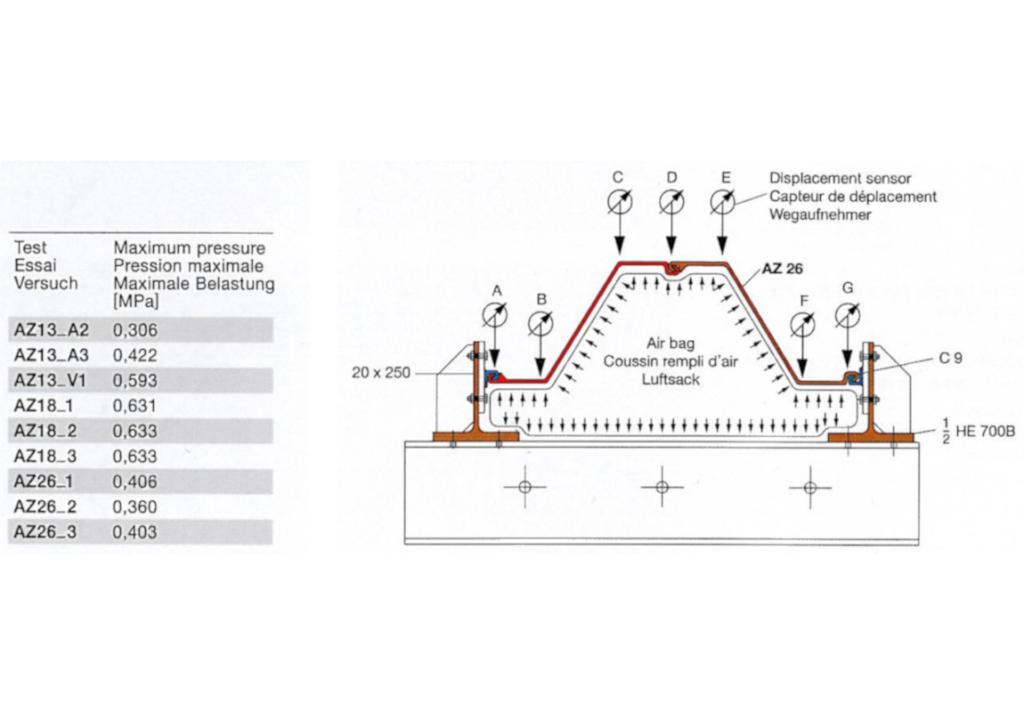

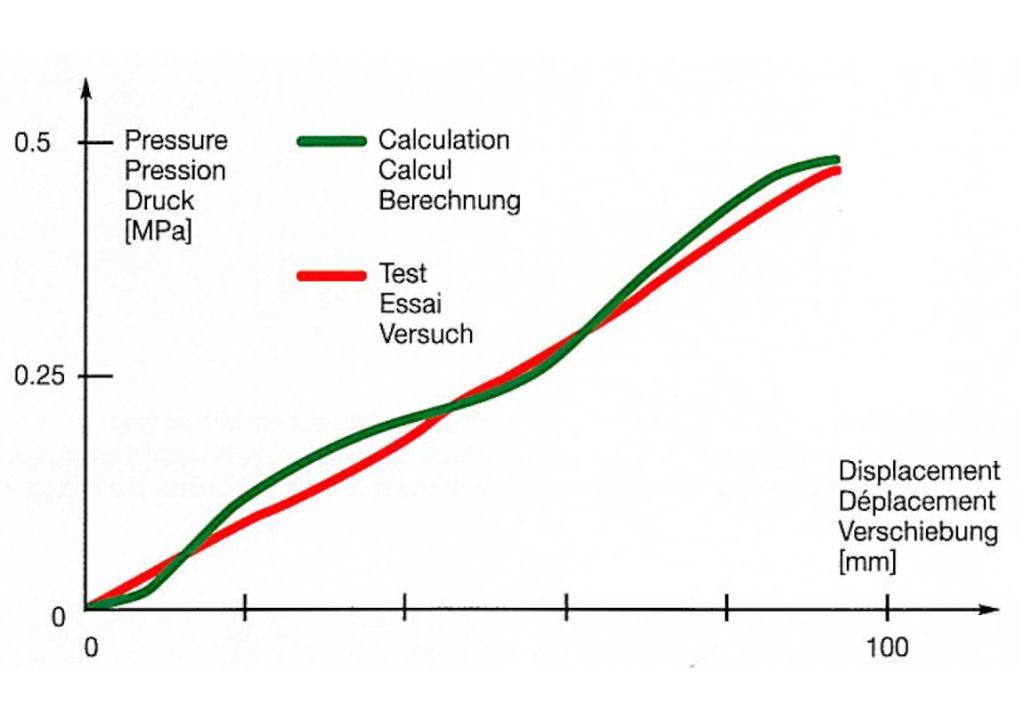

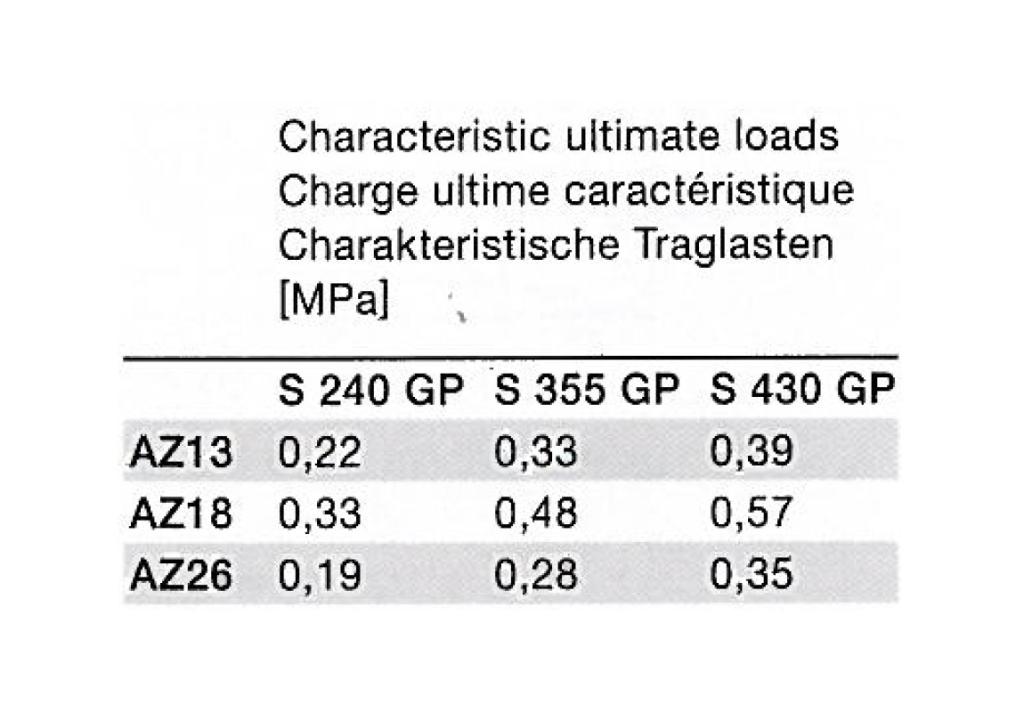

ArcelorMittal appointed Liege University's Structural Steelwork Department to conduct a detailed study to demonstrate the excellent behaviour of AZ sheet piles when used as intermediate sheeting in combined walls. This study included not only laboratory testing but also numerical simulations. It demonstrated that these sheet piles can in fact withstand a hydraulic head of more than 50 m without failing. It can therefore be said that a method for verifying AZ sheet piles based simply on the theory of elasticity can offer only a very uneconomic approximation of their actual behaviour.

(Section 8.1.4.2 of EAU1996 calls for verification of intermediate sheeting for water heads exceeding 4 m!).

This document is available in English, French, and German.

Download

English

English