Combined walls

CAZ & CU & tubes

Combined walls

Steel sheet piles can easily be combined to form special arrangements and create systems with large bending resistance. Combined walls built up with box piles (or HZ-M, or steel tubes) and standard sheet piles are one of these solutions.

The primary piles, or “king piles”, of combined walls can also be used as bearing piles. and can bear high vertical loads, e.g. crane loads. The intermediary sheet piles act mainly as soil-retaining and load-transferring elements.

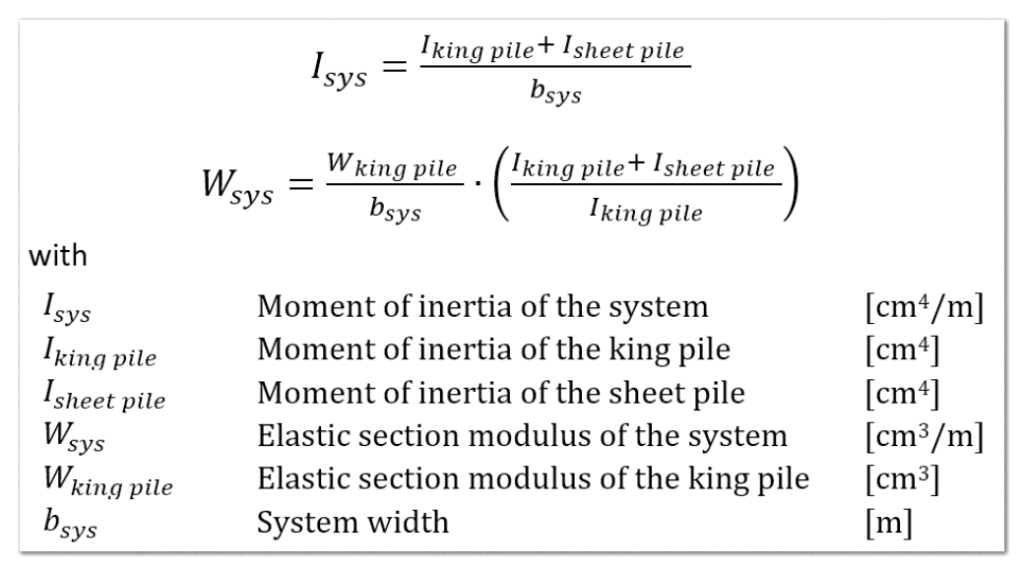

The equivalent elastic section modulus Wsys per linear metre, respectively per linear foot, of a combined wall is based on the assumption that the deflections of king piles and intermediary steel sheet piles are the same, leading to the following formulas

Technical database

Consult our products characteristics

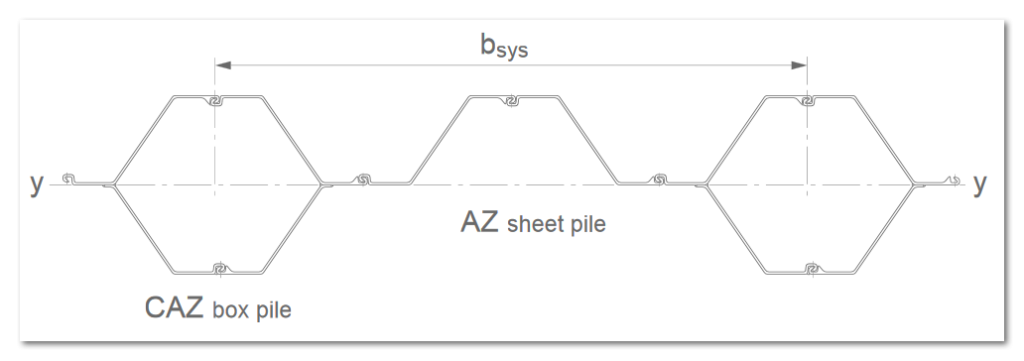

Combined walls with CAZ box piles - CAZ/AZ

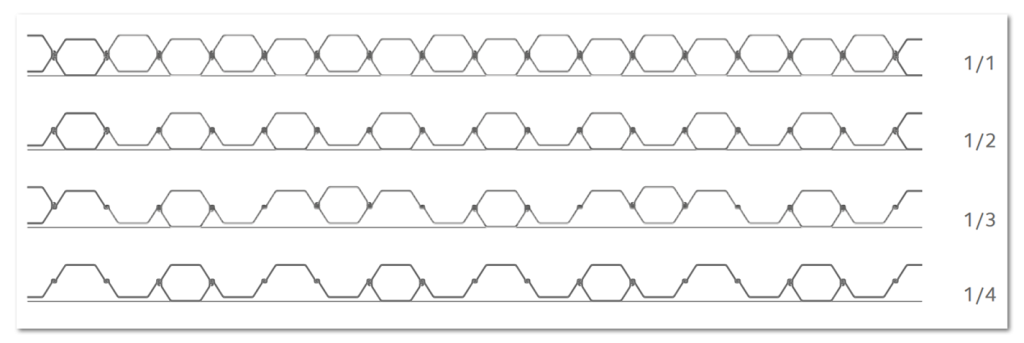

Combined walls built up with CAZ box piles and standard double AZ sheet piles:

There are several combinations possible to achieve high bending moments and moment of inertia.

Notes:

- the equivalent elastic section modulus shown in the tables is for the element that takes the largest stresses (lowest equivalent section modulus of the system);

- if the king piles have a different steel grade than the infill sheets, then the stresses in both elements have to be checked separately (with two different equivalent elastic section modulus!);

- the infill sheet piles AZ are usually lighter and shorter than the king piles;

- the fabrication of the CAZ box piles is quite expensive and time-consuming. It should only be done by experienced welders, based on a specific welding procedure.

Combined walls with CU box piles

Combined walls built up with U-type box piles (CAU-2 / CU-2 / CGU-2) and standard single, double or triple U-type sheet piles. There are several combinations possible to achieve high bending moments and moment of inertia.

These solutions are selected most often for retaining walls with a bearing function, where the box-piles increase the rigidity of the wall and/or the vertical bearing capacity, and are usually longer than the infill sheet piles.

Notes:

- the equivalent elastic section modulus shown in the tables below is applicable to the element that takes the largest stresses (lowest equivalent section modulus of the system);

- if the king piles have a different steel grade than the infill sheets, then the stresses in both elements have to be checked separately (with two different equivalent elastic section modulus!)

- for double and triple piles, the section properties shown in the table is based on the assumption that the common interlocks are either crimped or welded.

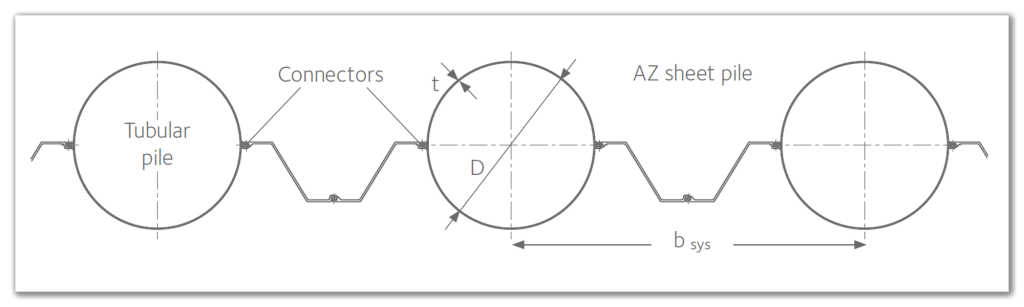

Combined walls - steel tubes and sheet piles

Combined walls with steel tubes are an alternative to the HZ-M/AZ system. Tubular piles are the main retaining elements of the combined wall (king piles), carrying horizontal loads from soil and water pressures and vertical loads from the superstructure or anchoring system.

The intermediary AZ sheet piles (infill sheets) transfer the horizontal loads from the retained soil and water to the tubular piles. Note that infill sheet piles are usually shorter than the king piles.

In some countries, U-type or cold formed steel sheet piles are used as infill sheets. ArcelorMittal does not recommend to use double or triple U-piles as infill sheets because of their reduced rotation capacity (interlocks are located on the neutral axis). Cold formed sheet piles have a looser and weaker interlock shape, so that ArcelorMittal does not recommend them as infill sheets.

One advantage of steel tubes is that they can be built-up from the same outside diameter tubes, but with different thicknesses over the length in order to adapt the resistance of the piles to the variable moments along the height. This solution is however only economically viable for rather long steel tubes because of the cost of butt-welding.

The main disadvantage of large diameter tubes is shipping (high cubage factor) and the weight of a single element to be driven (may require quite powerful driving equipment).

Buckling and torsion of relatively slender tubes may be a concern for high strength steels. A European project has studied these complex phenomenon for foundation piles and the results have been published a few years ago.

Tubular piles from ArcelorMittal are available in numerous European and US steel grades (large number of own facilities producing coils). The piles are provided with C9 connectors, which guarantees the minimum interlock hook connection (see EAU 2012), and can be coated on request.

ArcelorMittal Commercial RPS supplies spirally welded tubular piles manufactured in ArcelorMittal Projects’ mill in Dintelmond (NL). Tubes are delivered with EN 10204 - 2004 certification. The Dutch mill is equipped with a deep-water quay and can export tubular foundation piles with diameters up to 3000 mm, wall thicknesses up to 25 mm, and lengths up to 49 m without butt-welding.

The table below gives an overview of some of the possible combined wall systems. Please refer to our brochure “Spirally welded steel pipes” for further details.

Our projects

Learn more from real practical cases