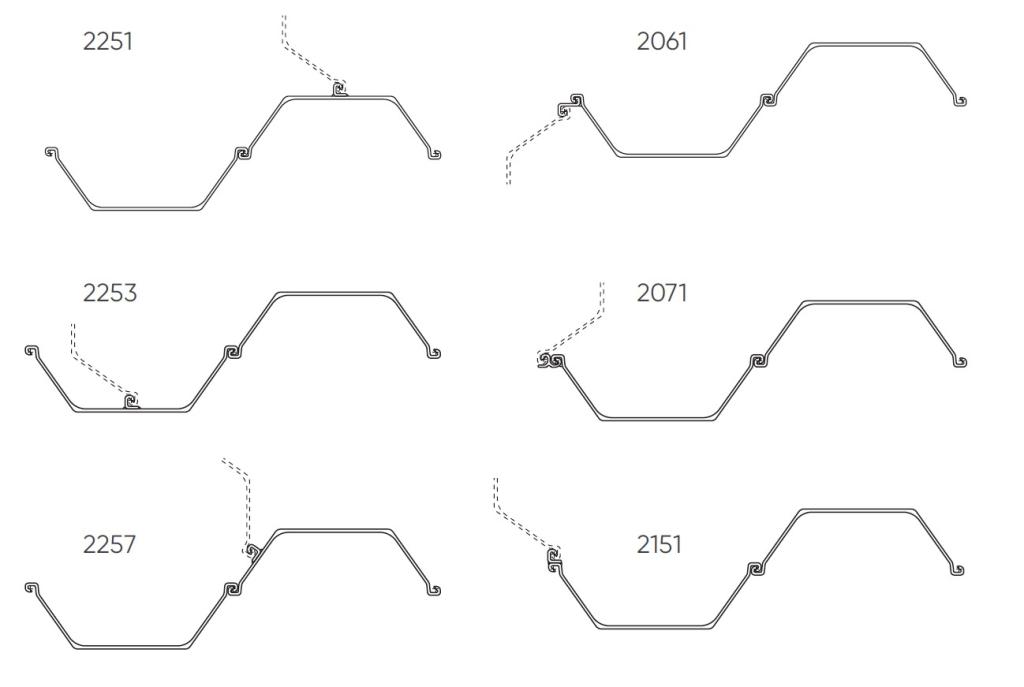

U sections

AU™, GU®, PU®

U sections

Millions of tonnes of U-shaped sheet piles have been used all over the world for all kind of structures for more than 100 years. The advantages of U-shaped piles are multiple:

- wide range of sections;

- excellent statical properties;

- great aptitude for re-use and driving into compact soils, especially the sections with reinforced shoulders (PU 22,...);

- very good installation quality and performance.

ArcelorMittal supplies 3 types of sheet piles from the mills in Belval (Luxembourg) and Dabrowa (Poland):

Technical database

Consult our products characteristics

All our U-type sheet piles have the proven Larssen interlock.

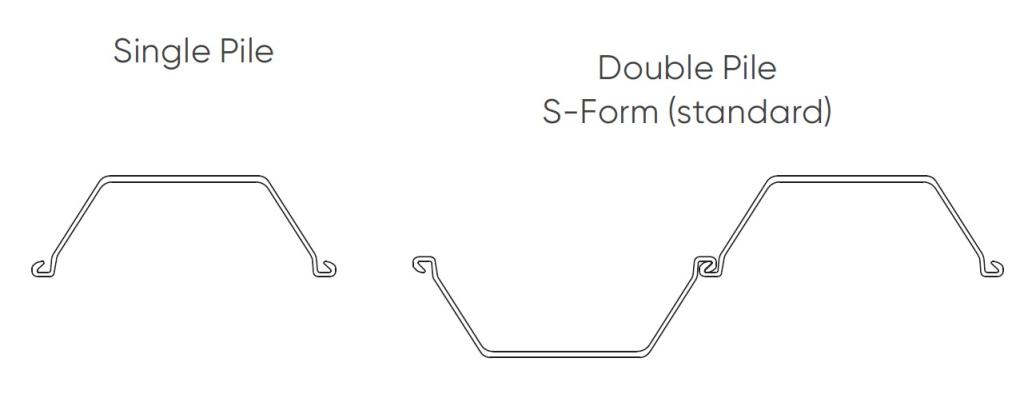

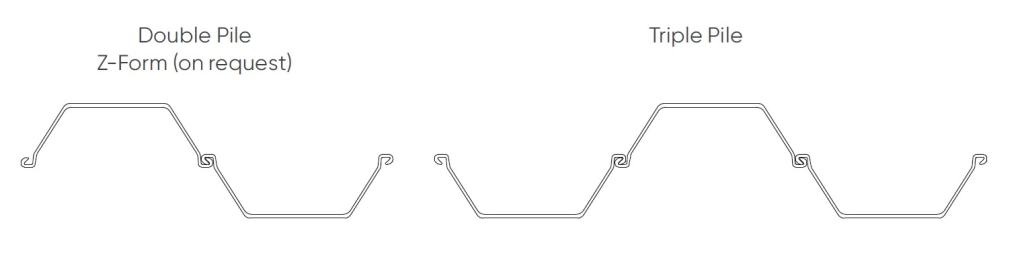

U-type sheet piles are usually supplied as double piles, with the common interlock crimped (several patterns are available), or welded (more expensive). Triple piles are usually supplied with one common interlock crimped and the second one (partially) welded.

According to European design standards (EN 1993-5): reduction factors may have to be applied to the section properties of double / triple U-piles (with crimped and/or welded interlocks), but for single piles (including double / triple piles without crimped / welded interlocks), reduction factors have to be applied.

Note:

PU®, GU® are registered trademarks of ArcelorMittal, AU™ is a trademark of ArcerlorMittal.

Interlock

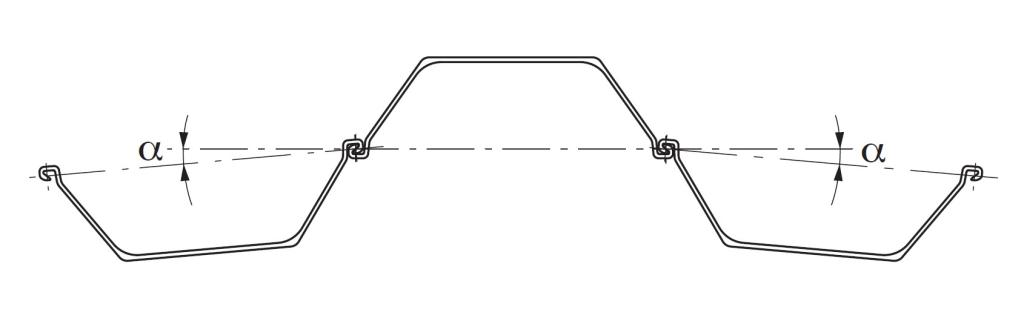

All AU™, PU® and GU® sheet piles feature Larssen interlocks in accordance with EN 10248. AU, PU and GU (except GU-400), as well as the AZ series, can be interlocked. Theoretical interlock swing: αmax = 5°.

Delivery form

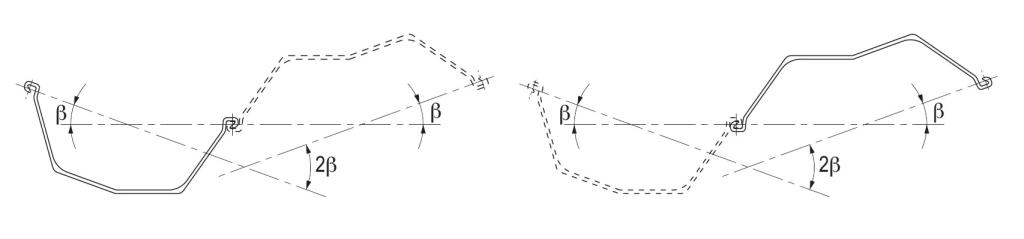

Bent piles

Maximum bending angle: β = 25°. U-piles are bent in the middle of the flange. They are generally delivered as single piles. Double piles are available upon request.

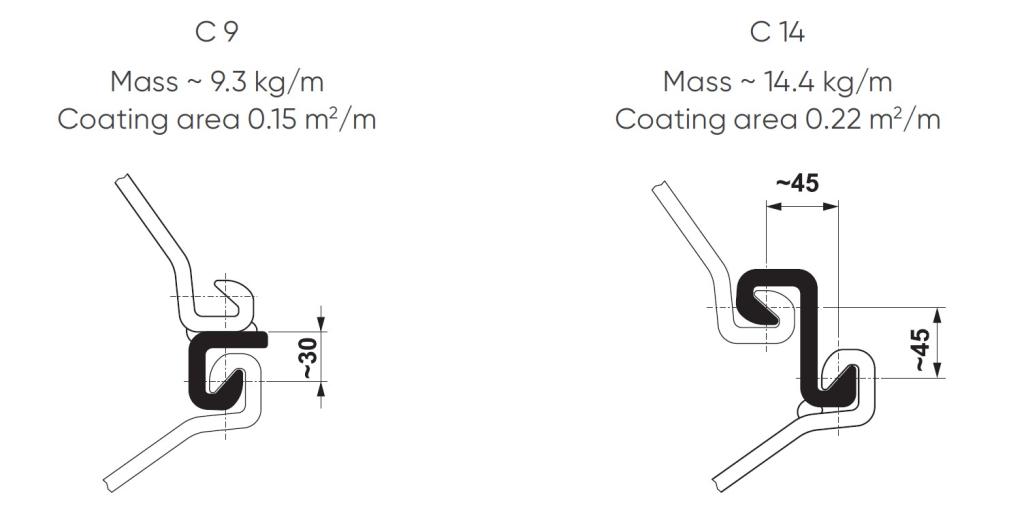

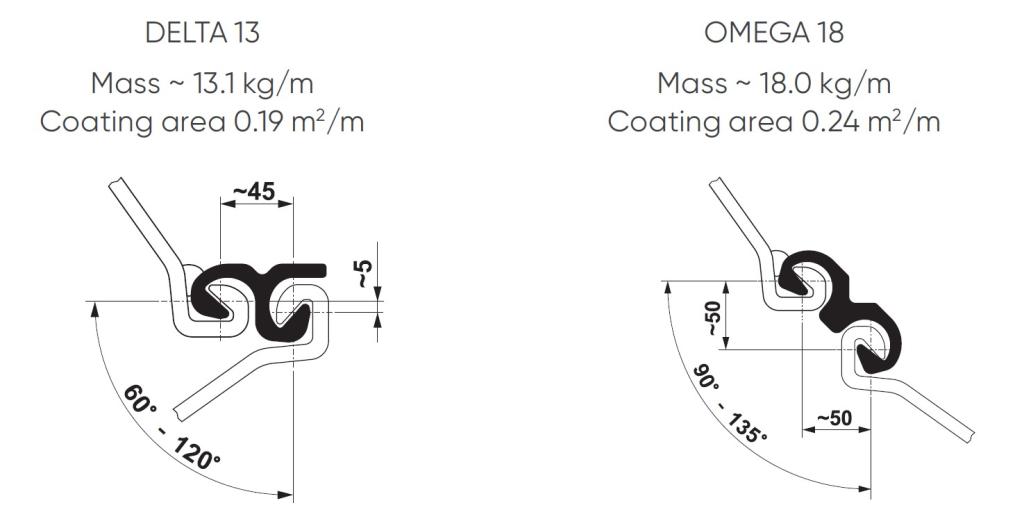

Corner sections

Special corner sections interlocking with U- and Z-sections make it possible to form corner or junction piles without using fabricated special piles. Corner sections are fixed to the sheet pile in accordance with EN 12063.

Different welding specifications are available on request. The corner sections are threaded and welded with usually a 200 mm setback from the top of the piles.

Fabricated piles, corner and junction piles

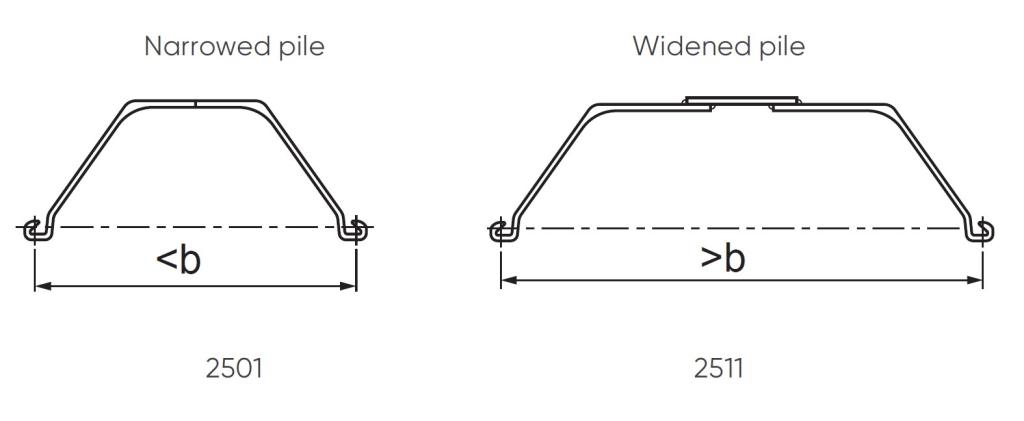

On request, arrangements can be made for widened or narrowed fabricated piles. The following special piles, among others, are available on request as single and double piles.

Our projects

Learn more from real practical cases