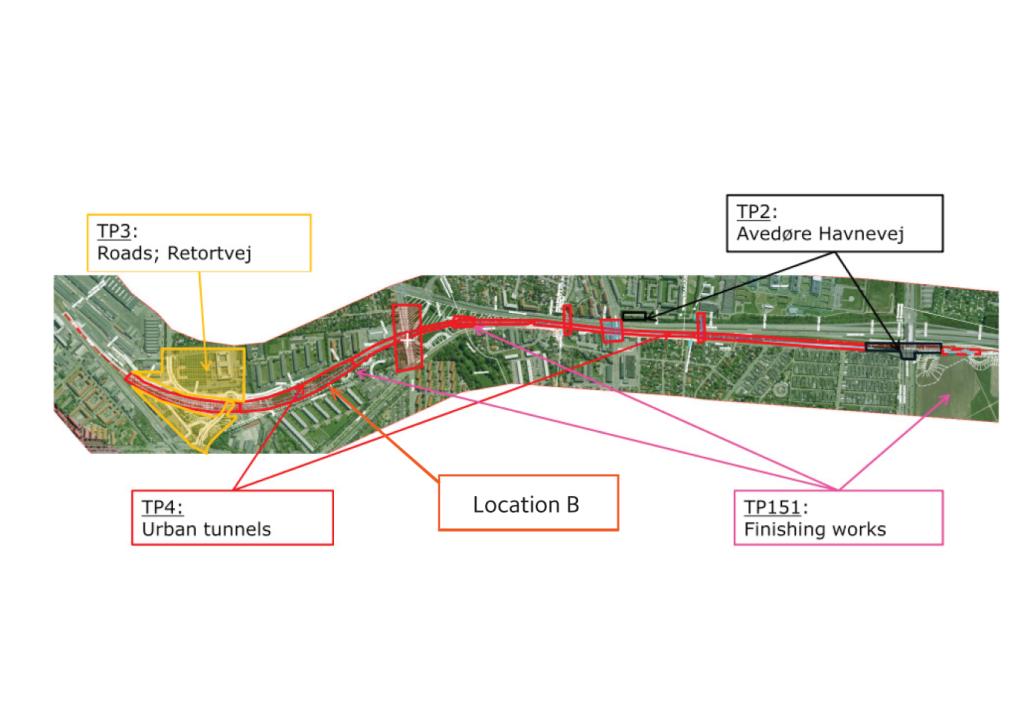

Copenhagen-Ringsted Highspeed Rail (TP4), DK | 2014

The Cutting-Edge project for building Denmark's first Dual-Track railway for high-speed trains in Copenhagen

Banedanmark - a state owned government agency under the Danish Ministry of Transport, responsible for the maintenance and traffic control of the Danish railways - is in the process of building a new dual track railway between Copenhagen and Ringsted via Køge.

The proposed Copenhagen to Ringsted Railway Line covers a total distance of approximately 60 km and passes through 10 municipalities with the aim to provide extra capacity, faster trains and more flexible time tabling along this vital railway corridor. This new railway line will connect with the existing railway system in Copenhagen and Ringsted. It will run through densely populated and trafficked areas as well as historical, cultural and recreational locations.

Download

English

English