Spirally welded steel pipes

Innovations in Construction: The Benefits of Spirally Welded Steel Pipes

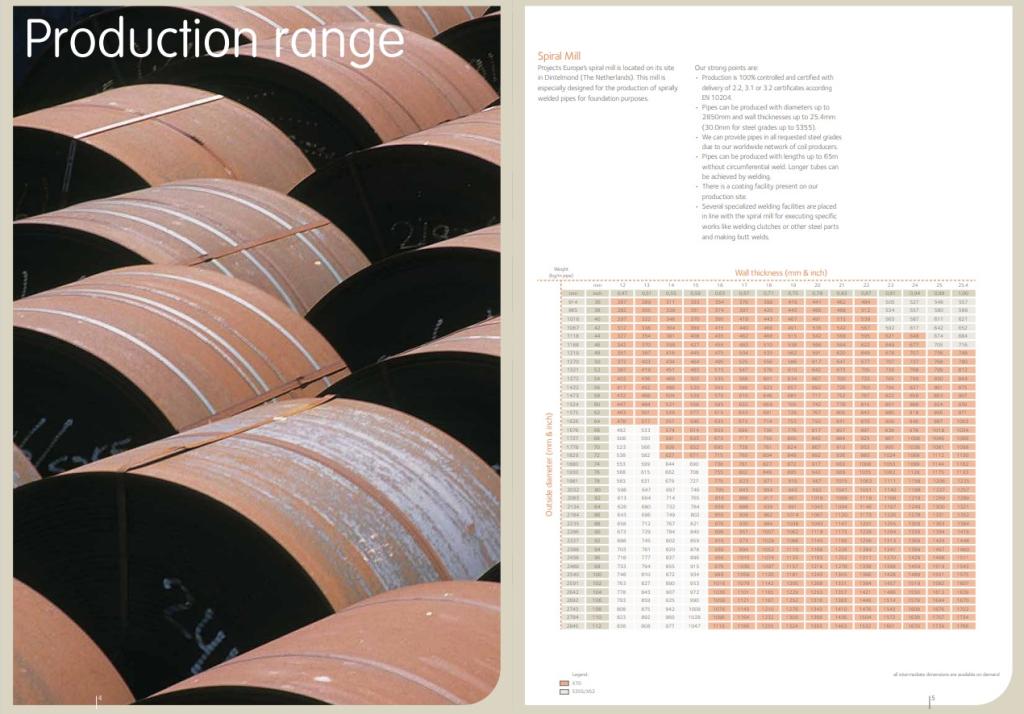

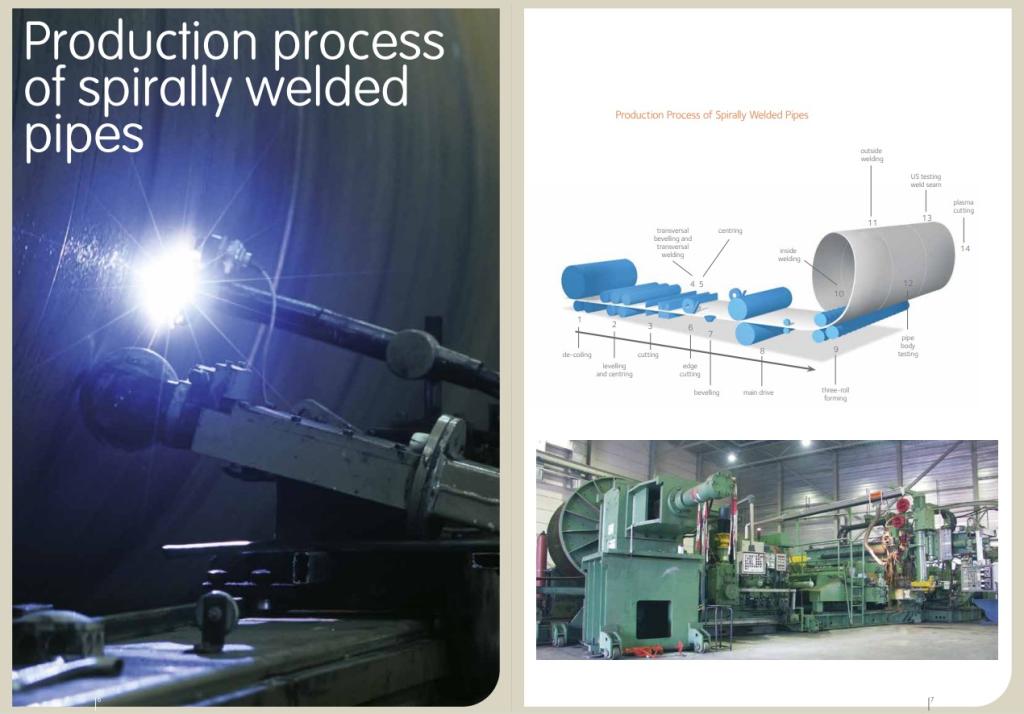

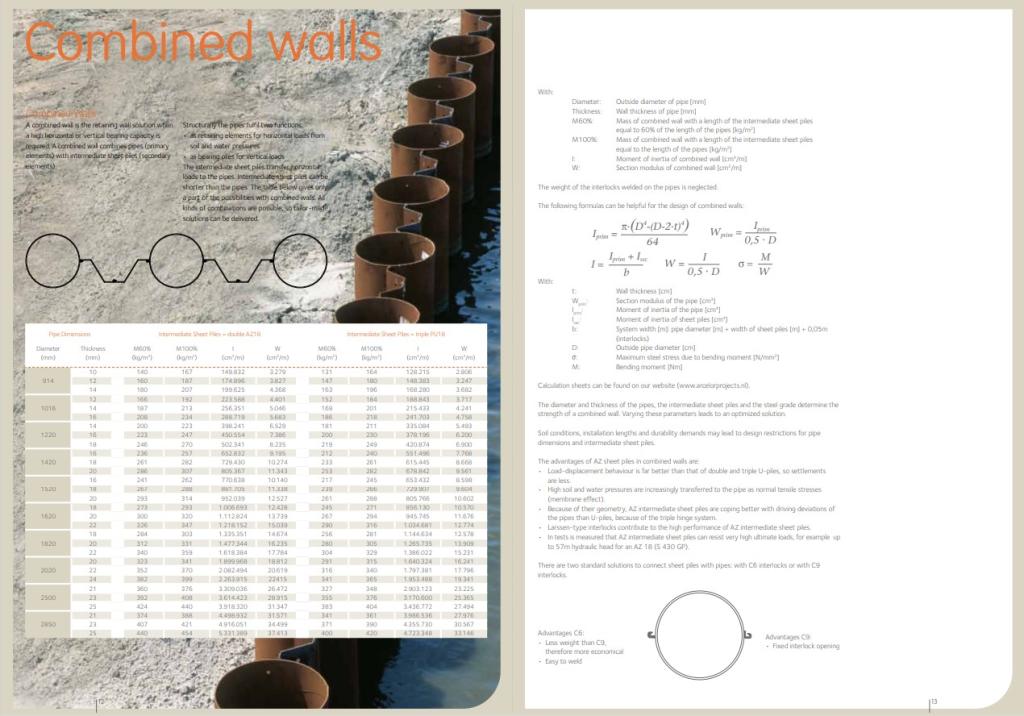

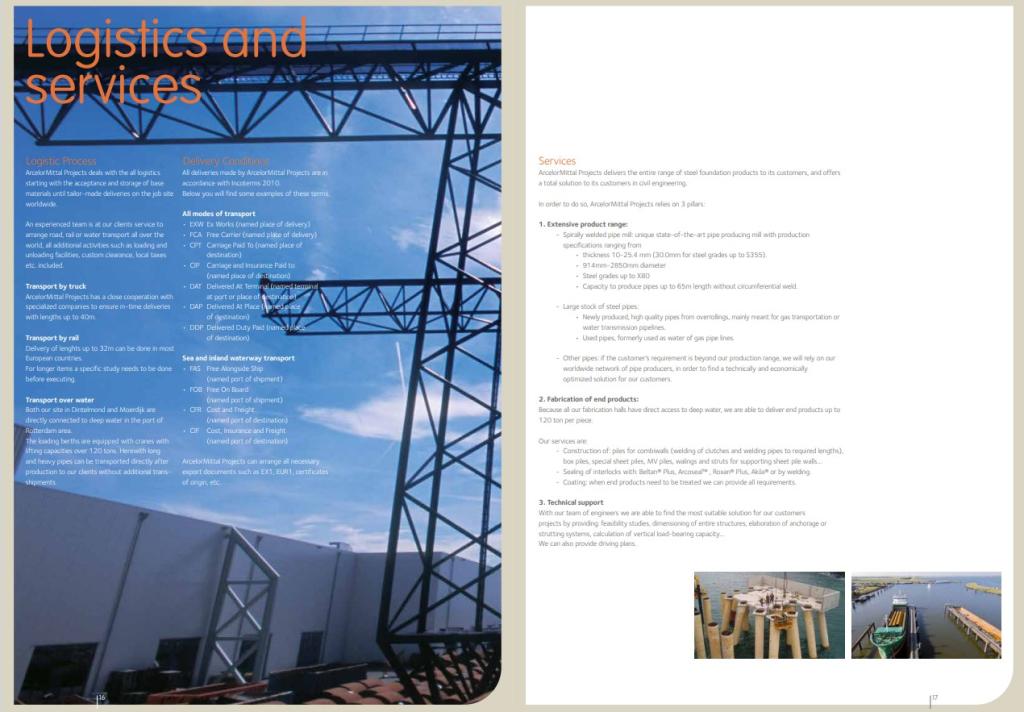

Steel tubes used in foundation works, either as piles or as king piles of a combined wall system. These are spirally welded and manufactured in our mill in the Netherlands.

Download

English

English