Water Transport Solutions

Watertight retaining wall

- AZ

1 300 tonnes of sheet piles

3 000 tonnes of HP Piles

Opera & Ballet, Oslo, NO | 2003

Download the full case study

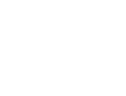

The building has around 38 500 m² and more than 1 100 rooms, spread over 4 levels and a basement, divided in following sections

- the public area with access from the area adjacent to Oslo Central Station, encompasses the foyer, and 3 auditoriums, where the main auditorium has seating for up to 1 350 people. The Main auditorium is a classic horseshoe shaped opera theatre with a high-level ceiling designed to strict acoustic requirements. The foyer area is a large, open room with varied natural lighting and fine views of the fjord and Hovedøya

- the stages - the Opera House has one of the most modern and technologically advanced opera stages in the world. The 35 m high stage tower is located above the main stage, allowing for complicated theatre-technical solutions

- the production section contains workshops, stores, rehearsal rooms, cloakrooms, offices and audition rooms

- the roof landscape is open to the public. The horizontal and sloping roofs express monumentality and give the building a dramatically different appearance than its neighbours. The cladding of the roof landscape is made with white Italian marble that adds a brilliant artistic effect to the building envelope

The Opera House functions as a link between the historic downtown Oslo to the west and the Ekeberg hills to the east. It is a cornerstone in the development of a completely new borough. For decades Bjørvika was known for its harbour activities and heavy traffic. The final goal is to convert this part of the City into a vibrant and attractive area for commercial use, dwellings and cultural activities. A premise for this development was the transfer of the E18 motorway into a submerged tunnel passing under Bjørvika.

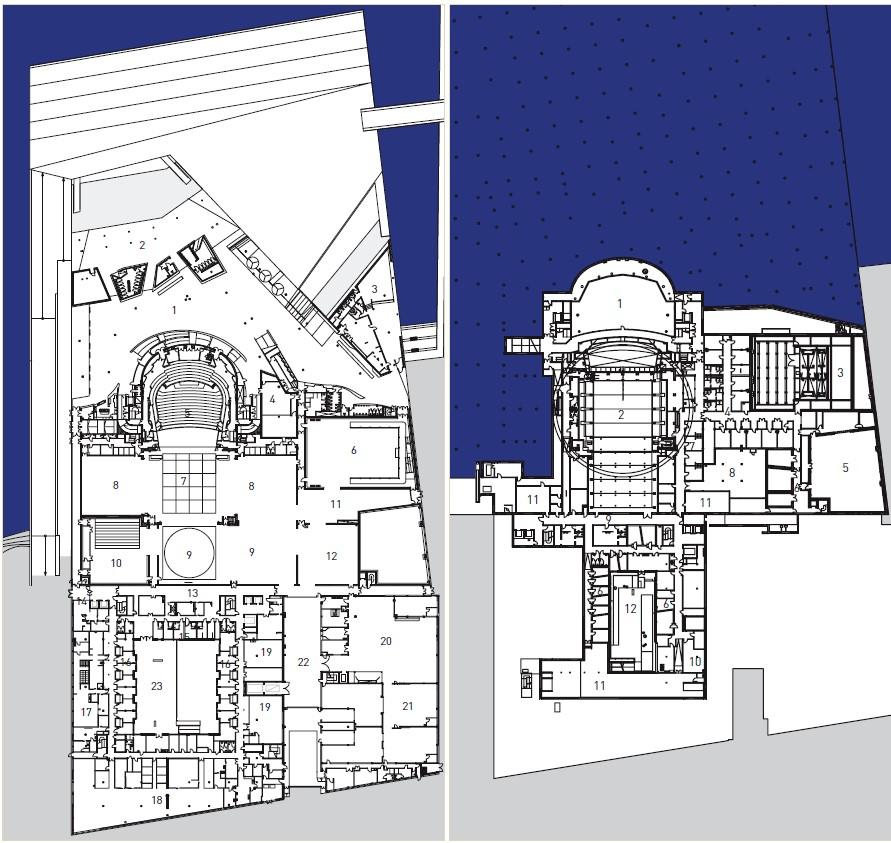

Foundation works

A large part of the structure lies under the sea level, which posed a major challenge to the execution of the foundations. Besides, a large quantity of polluted soil masses had to be removed and transported to a treatment plant or to a landfill. Pumping to reducegroundwater level and finally the full waterproofing of the building foundations were supplementary difficult tasks.

ArcelorMittal supplied around 1 300 tonnes of AZ steel sheet piles to build a dry working area, which represents 12 000 m2 of retaining wall. The sheet piles were driven into the soil with the interlocks treated with the Roxan® sealing system to achieve a very watertight excavation enclosure. The deepest point of the excavation lied 16 m below the surface of the water, a major challenge for the foundation contractor: the structure of the main stage was built inside a circular cofferdam with a diameter of 40 m, for which the excavation and casting of up to 2.0 m thick bottom concrete slab was carried out as underwater work with extensive use of construction divers. The excavation started in the dry down to elevation -8.6 m using 3 levels of bracing (concrete ring), then the pit was filled with water and the rest of the excavation down to elevation -16.0 m was performed underwater. The water was finally pumped out after pouring the bottom slab and further work on the basement was carried out without any difficulties.

Part of the building is built over the sea. The slab is at an elevation of 2.6 m above the water level and is founded on approximately 28 km of HP steel piles driven down to bedrock. The piling foundations have been designed for a lifetime of 300 years, hence the HP piles are encased in a steel tube of 600 mm diameter, filled with a fibre armoured concrete poured inside the tube up to its head to protect the HP pile from corrosion. The piles were driven down to the bedrock, some of them reaching 60 m under the water surface.

The Norwegian Pollution Control Authority (SFT) imposed very strict rules for the handling of the polluted soil. Approximately 12 000 m3 of polluted mass were removed, sorted in accordance with degree of pollution and disposed of accordingly. In addition, an area of approximately 20 000 m2 of polluted ground was sealed off by a minimum of 50 cm of clean sand filling. A total of 90 000 tonnes of polluted materials was excavated and transported to the approved depot on Langøya near Holmestrand.

The project was carried out in close cooperation with the final user, Den Norske Opera, which is Norway’s largest music and stage arts institution. It is the national producer and presenter of opera, ballet, music and dance theatre and concerts.

Extra challenge: archeological remains

Bjørvika is filled with a several metre thick layer of sawdust and chippings from the sawmills that operated along the Aker River as early as the 16th century. This layer helped conserving objects lying on the bottom. Many boats and other artefacts lie under what is now dry land. An important premise for the building permit was thus that the site was to be thoroughly inspected and surveyed for archaeological finds. Archaeologists were present at the building site watching over every single grab load removed. A total of 2 000 large and small objects were found during this phase of the construction works.

Awards

The national Opera received the European Union Prize for Contemporary Architecture - Mies van der Rohe Award 2009, a joint initiative of the European Commission and the Fundació Mies van der Rohe.

Summary

Timeline

- 2003 Foundation works commences on February 17th.

- 2004 The foundation stone is laid by H. M. the King on September 3rd.

- 2007 The construction project is completed during the winter.

- 2008 Moving before the Opening Gala on April 12th.

Characteristics

| Gross area | 38 500 m² |

| Building length | 207 m |

| Building width | 110 m |

| Max. ceiling height above stage | 54 m |

| Depth of stage below sea level | 16 m |

Project cost

| Construction project | NOK 4.36 billions |