Environmental Protection Solutions

Dyke reinforcement

925 tonnes of sheet piles

Dyke reinforcement of the drinking water plant, FR | 2012

In 1961, the Paris City Council decided to build a new surface water treatment plant to cope with the constant increase in the supply of drinking water. Inaugurated in 1969, the plant occupies 52 hectares on the banks of the Seine, on the site of a former ballast tank.

Download the full case study

The land, which was originally flooded, was filled in except for the basins, which cover more than 5 hectares and form a dock with a capacity of 300,000 m3 of water. In the event of contamination of the river, this gives the plant 24 hours' autonomy at full capacity.

Built in 1988, the north dyke of the dock is made up of embankments, with a plastic concrete veil to make it watertight. The level of the dyke supports the walkway. Following the collapse of the dock in 1992, the banks on the dock side were initially reinforced with a sheet-pile wall anchored at the foot of the dock at 26.5 NGF and crowned with a concrete beam.

In recent years, there have been shifts in the capping, settling of the walkway and further collapse of the embankment. In addition, the presence of water in a wooded area on the other side of the dyke, with a fluctuating level parallel to that of the dock, indicated that water was flowing under the dyke. Clearly, the existing dyke was no longer watertight. The main cause was inadequate anchoring (plastic concrete veil anchored in the marl at 23~24.0 NGF, sheet piling in the embankments at 26.5 NGF).

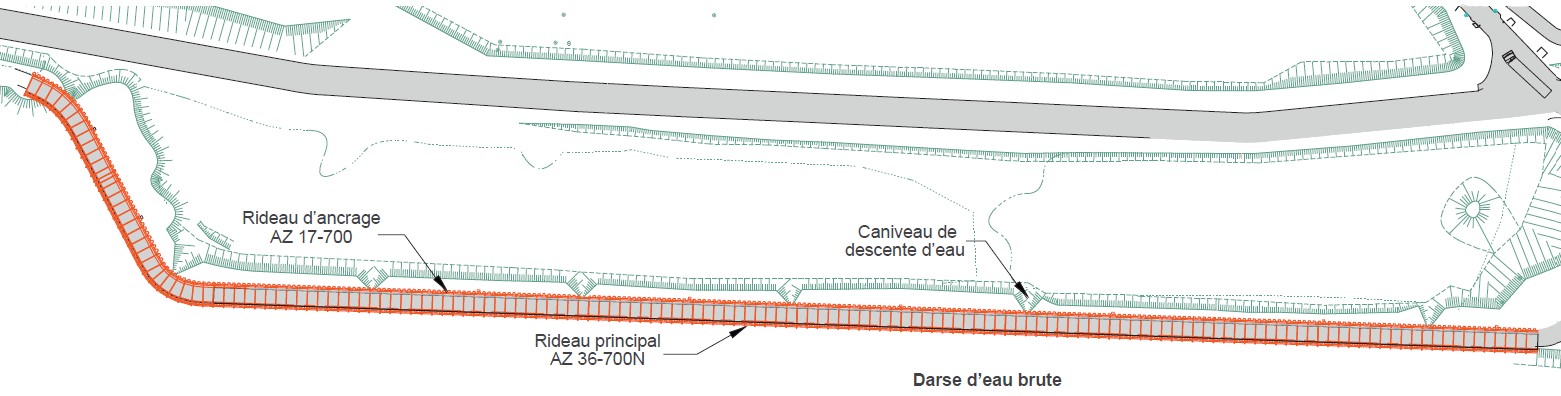

To avoid long-term ruin, a new reinforcement project has been launched. This involves installing a main sheet pile wall and an anchor wall, each 390m long, to ensure the stability of the dyke in normal use and in the event of flooding of the Seine with an empty dock. This is for a lifespan of 100 years.

The first version of the project envisaged a sheet pile wall connected to a sheet pile anchor wall, but the latter was located in the wooded area behind the dyke. In order to save as many trees as possible, additional geotechnical tests were carried out. These tests led to new, more favourable calculation assumptions, which enabled the anchoring wall to be moved closer together. The optimisation adopted includes AZ 36-700N sheet piles 14.0 m long in the main wall and AZ 17-700 sheet piles 5.0 m long in the anchor wall, with the sheet piles at 20.5 NGF and 28.5 NGF respectively.

The work was carried out in several phases. It began with the impoundment of the dock at 32 NGF, followed by the earthwork of the embankments of the walkway to a depth of around 1.7 m above ground level, and the cutting or drilling of the existing wall for the installation of the anchors. After the installation of a driving guide, the sheet piles were driven using PVE 38 M and PVE 25 M vibrators over lengths of around 10 m, followed by the installation of the tie rods and tie bars. Where necessary, a Dawson HPH 2400 hydraulic hammer was used for over-sinking.

The tie-rods, spaced at 2.5 m intervals, were installed as the project progressed, and the space between the new and old sheet piling was filled with lean concrete. The final phase was to create a concrete capping beam at the head of the main sheet pile wall and rebuild the breakwater to its original state.

Work began in June 2012 and was completed in January 2013. A total of 925 tonnes of sheet piling will have been used in this embankment reinforcement project.