Environmental Protection Solutions

Excavation support

110 tonnes of sheet piles

Isenmühle weir in Heldenstein, DE | 2020

Download the full case study

Due to structural damage, the Isenmühle weir was undermined in April 2020 and the backwater behind the weir quickly dropped by 1.5 metres. A week later, an oxbow lake was almost dry, aquatic plants were drying up and a number of larger fish were cut off from the main stream. The engineering firm AquaSoli from Traunstein was under enormous time pressure to develop a solution to restore the waterway to its pre-flooding state as quickly as possible and to minimise the ecological impact. The weir could no longer be repaired and had to be demolished and replaced by a ramp with closed deck work.

The solution involved the immediate construction of a stone dam upstream into the water at the Isen weir.

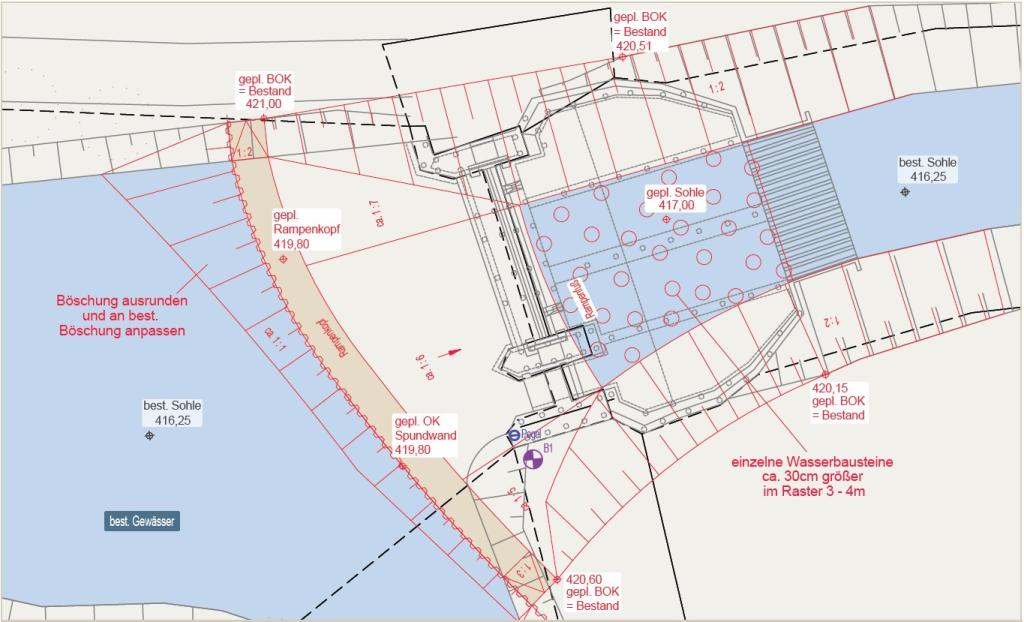

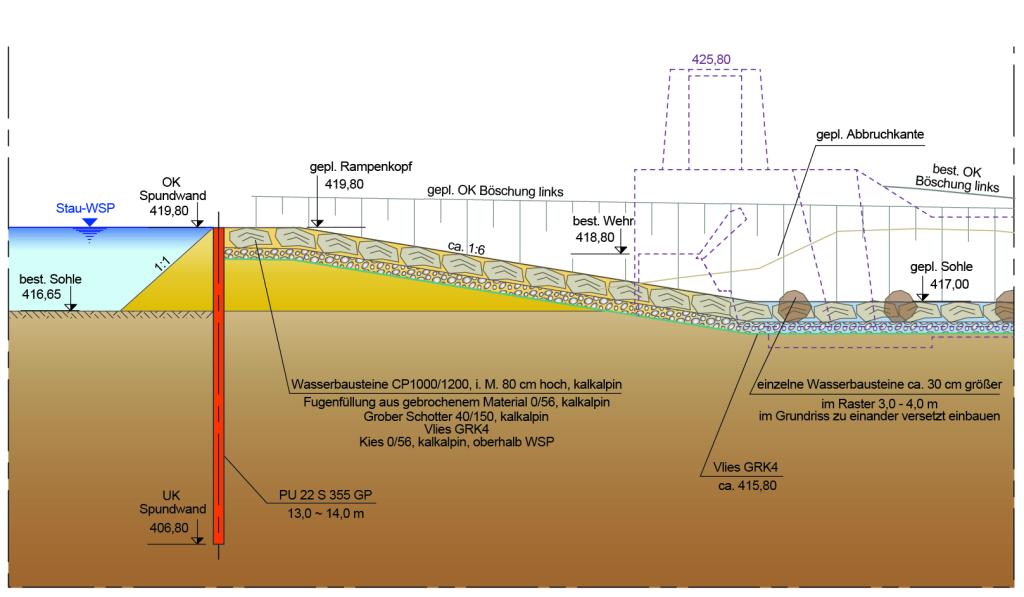

This allowed the water to flow back into the Isen tributary in a timely manner, restoring the water level above the former weir. This dam consists of a sealed embankment of coarse gravel, which was also used as a construction road and pile driving planum during the construction work. The dam and various construction stages were planned using a two-dimensional discharge calculation:

- while maintaining a damming objective, the water discharge could be diverted to the headrace channel;

- a flood discharge could be easily diverted over the construction site, thus ensuring efficient dewatering.

Steel sheet pile section PU 22 was installed in the headwater of the existing weir structure to prevent underflow at the existing weir structure, to secure the excavation pit during the concrete demolition work and as a sealing element for the planned ramp structure. As the weir was in danger of collapsing, the axis of the sheet pile wall was moved approx. 12.0 m upriver from the weir threshold, and was thus outside the range of the towers for the tension elements of the weir flap. In this position, the sheet pile wall served to secure the excavation pit and the top of the ramp. Sections without interlock sealing were used to ensure seepage and thus a fresh water supply for the downstream water. Despite difficult ground conditions and adjacent buildings, the 13.0 m long sheet piles could be installed without difficulty down to the tertiary. The trouble-free installation of the sheet piles was favoured by the many years of experience of the pile driver and the selected sheet pile profile PU 22 with a thickness of 12.1 mm. Where necessary, obstacles consisting of a set of stones, the existing wooden pile foundation and blocks were removed.

The armourstones of the ramp were placed on the gravel layer. The joints were filled with native gravel and coarse crushed stone. The ramp head, including the upper 3.0 m of the ramp revetment, was constructed in a smooth manner using the setting method. The remaining ramp revetment and the area of the former weir floor were instead given a rougher finish.

The existing weir, including the stilling basin, was demolished in sections. Cavities and washouts in the base area were filled.

The measure described was an emergency measure due to the imminent danger. The work was carried out under difficult conditions. The construction site, including transport permits and the provision of sheet pile profiles, was organised in just four days and work began the following day, so that the waterway could be secured within a week. Only eight hours after initial contact, the first delivery of sheet piles for the permanent ramp structure left the manufacturer.

The project is an example of a remarkable joint effort by the companies involved.