Hazard Protection Solutions

Flood and Environment Protection

2,457 tonnes of sheet piles

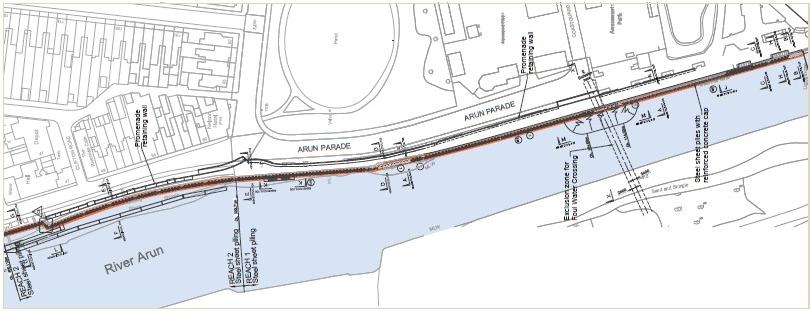

Littlehampton Tidal Flood Defences, UK | 2014

Completed at the end of 2014, the scheme protects 2,000 residential properties and businesses against 75 years of predicted sea level rise as well as enhancing the riverside walkway between the town and the beach.

Download the full case study

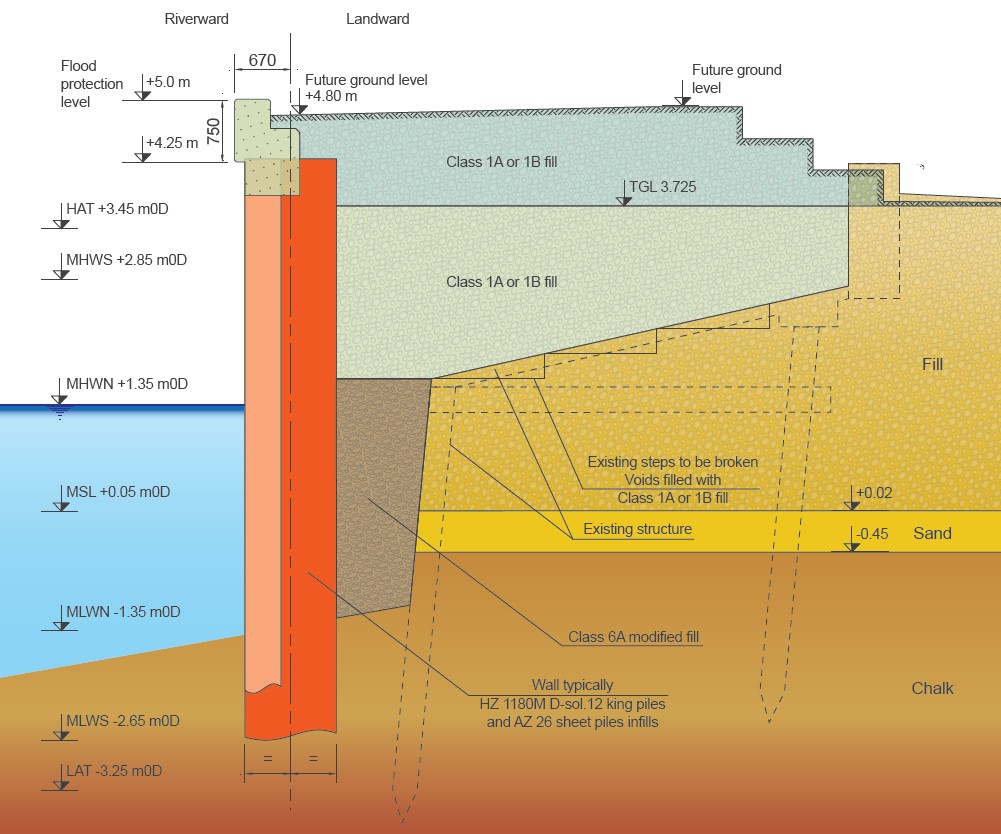

Two types of retaining wall were considered for the structure which has to withhold up to 6.9 m soil and ground water without lateral support. Initially a tubular wall in combination with AZ® steel sheet piles was thought to be the most economical but on consideration of the long design life, the HZ® / AZ® combined wall system from ArcelorMittal was found to be the most economic and technically feasible solution.

It utilises large HZ®-M (HZ 1180M A-sol.12 & HZ 1180M D-sol.12) beams with welded interlocks, which are installed by panel driving techniques down to the required levels before AZ 26 sheet piles are driven to connect the beams into a continuous wall. The beams carry the vast majority of the bending moments and have the advantage that the face of the beam is small in comparison with a tubular solution. CH2M Hill had to take great care over assessing the design life of the structure, which at its most aggressive depth had to tolerate up to 7.2 mm thickness loss through the design life of the flood wall.

When analysing the two solutions the HZ® / AZ® was found to be stronger after sacrificial losses in comparison with the same losses from the tubular solution. This resulted in the significant cost saving by utilising the HZ® / AZ® solution.

All of the solutions where analysed and priced with ArcelorMittal included as part of the project team with the “Early Supplier Involvement” service.

Soils typically consisted of made ground with overlying chalk of varying strength. The made ground was the result of previous port construction (and activity) and was very varied. It included obstructions and cobbles. The chalk was weak in the upper layers, but increased in strength with depth and had flints and cobbles within the matrix.

The installation was carried out by VolkerStevin. Very robust driving frames have been constructed such, that the lower frame was close to high tide level and then the wall was installed with a combination of vibratory techniques (PVE 40VN) and noise shrouded percussive techniques (BSP CX85 in 7 Tonne mode and BSP CX110 in 9 Tonne mode). All equipement was heavily shrouded with double skin acoustic shrouding to keep noise levels to a minimum.

The site worked through some very difficult conditions with the wettest winter for some years, in conjunction with long periods of gale force winds. The installation works on Reaches 1 & 2 have been successfully completed with piling work moving to higher reaches using conventional AZ® sheet pile walls.