Mobility Infrastucture Solutions

M25 “London Orbital Motorway”, UK | 2009

Download the full case study

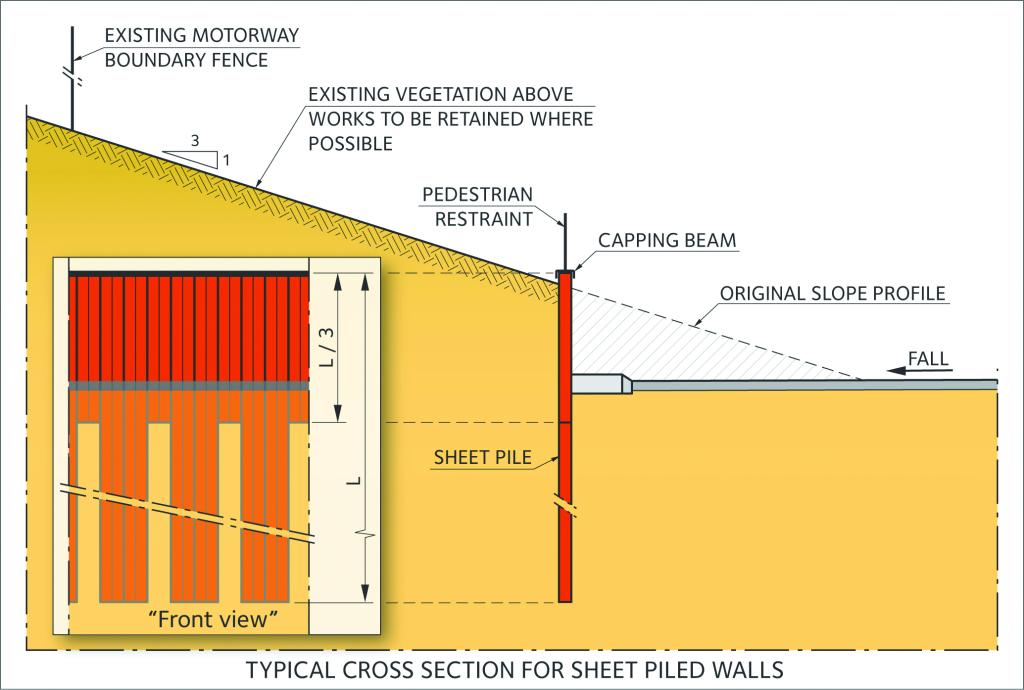

Section 1 Junctions 16 – 23 of the widening was broken into 3 sections of approximately 7.5 miles each with much of the work being in cut and with many overbridges. Adding a fourth running lane, quickly and efficiently, whilst minimising disruption to the road users and maximising staff and user safety during and after construction, presented no small challenge. Since much of the existing motorway is in cut with quite steep embankments leading down to the hard shoulder, to construct an extra lane required permanent retaining walls and regrading of the embankments.

The project manager analysed several construction methods. The reduced construction programme offered by steel sheet piling was the winning factor.

The site investigation indicated hard driving with stiff clays. Balfour Beatty specified a staggered combination of piles called the King Sheet Pile (KSP) system for which a patent has been applied. KSP uses a heavy pair of AZ sheet piles in long lengths interspaced with shorter and lighter AZ piles. This retaining wall system offers the advantage that not all of the piles have to be driven into the harder strata which facilitated faster installation speeds.

Clearly the KSP system presented the subcontractor with a logistical challenge ensuring that five piling rigs were constantly supplied with the correct mix of sections and lengths, but they were able to call off the materials wall by wall which greatly simplified the logistics.

The chosen sheet piles were the ArcelorMittal AZ ranges (including AZ 12-770 to AZ 37-700 and AZ 13 – AZ 48) acting in cantilever with some retained heights over 5 m. Many of the initially “soft” structures have been converted to AZ piles to benefit from the much faster construction speeds. Sheet piling installation proved not to be affected by the winter weather whereas other materials may well have been delayed by the heavy rain followed by freezing conditions which summarised this typical English season. The joint venture employed three ABI Leader Rigs with MRZV-V vibrodrivers and one Bauer Leader Rig with MR 125 V vibrodriver. Actually, installation was faster than expected, the original programme was for the first 22,000 m2 to be driven in 40 rig weeks but was achieved in only 28 rig weeks. Peak production of 1,375 m2 in a 5 day week was achieved which tested the logistics chain. The first batch of AZ sheet piles was ordered in loose pairs but for even faster installation later orders were for crimped pairs.

With excellent planning before commencement, optimal efficiency of design using the AZ range of sheet piles from ArcelorMittal and the very professional execution of the piling installation combined to ensure this project was a total success for all involved.