Water Transport Solutions

Rhône Canal Modernization, Sète, FR | 2012

Download the full case study

The work, which will continue until 2018, is being carried out in partnership with the Languedoc-Roussillon region, at a cost of €100 million.

This economically ambitious project is also environmentally ambitious. All along its route, the canal passes through sensitive areas that must be preserved during the works: the coastal ponds of the Hérault region, the wet plain of the Camargue Gardoise and listed sites.

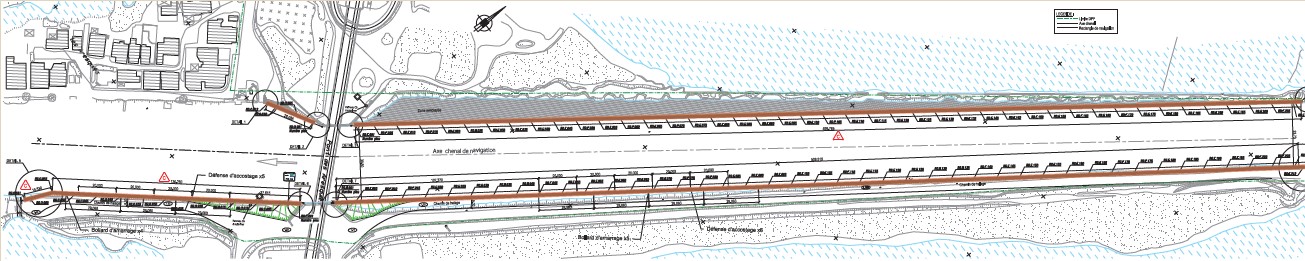

Work on the Aresquiers crossing area began in October 2011 and will take around 16 months to complete. Verticalization of the banks will enable the navigation rectangle to be widened locally to 34 m from the canal ceiling, over a linear distance of 650 ml on the left bank and 540 ml on the right bank. The transit of larger commercial vessels will increase from the current 900/1000 tonnes to 2300/2500 tonnes.

a little history....... During the reign of Louis XIV, Vauban and Pierre-Paul Riquet built the port of Cette (Sète) and the Canal du Midi respectively. As wealth grew in the western part of the province, the decision was taken to build a navigable canal in the eastern part, linking Sète to the Rhône. Today's Canal du Rhône à Sète is the result of the merger of the three former canals des Etangs, de la Radelle and de Beaucaire.

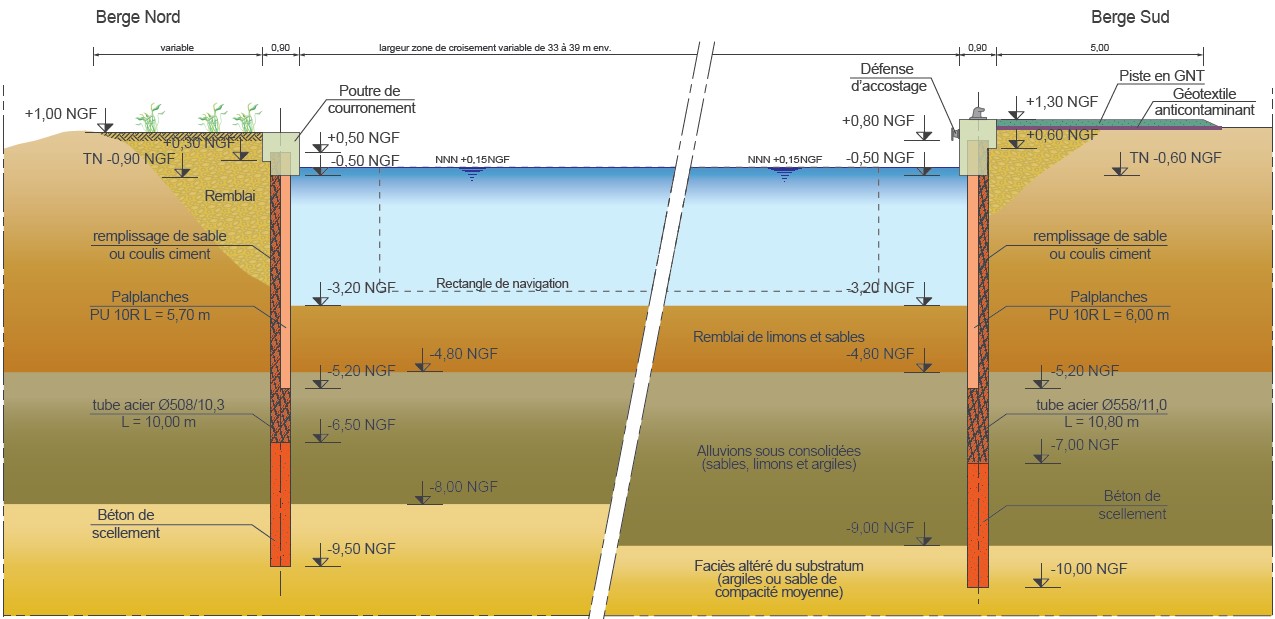

The presence of an indurated horizon (limestone and marl) at shallow depths (around -8 m NGF) led to the choice of a combined retaining wall solution.

The retaining wall is made of steel tubes and 3 intermediate PU 10R steel sheet piles. The tubes are the main elements of the combined curtain, absorbing the horizontal forces corresponding to earth pressure and hydrostatic pressure, as well as the vertical loads of the structures.

Intermediate sheet piles transmit horizontal forces to the tubes.

The first phase of earthworks consisted in removing the riprap from the banks in the area of the curtains. The curtains were then installed in two ramming workshops, one on land and the other on a barge. After installation of the two-level pile driving guide, driving took place in the following order: one tube, 3 sheet piles and then 1 tube, using a PTC 25 H2 vibratory hammer and an ICE 416, both mounted on a cable crane. The tubes were then anchored at the foot, at -10.0 m NGF on the left bank and -9.5 m NGF on the right bank, using a Delmag D22 diesel Hammer. In the more heavily indurated area to the west of the bridge, drilling from inside the Tube is required to reach the design elevation. The verticality of the curtain is constantly monitored during the Driving operation.

To ensure a 50-year service life, the sheet piles are coated on one side only and over their entire length with an ACQPA Im2A NI 631 anti-corrosion paint system. The tubes are protected by this paint system over a length of 5 m.

After recutting the curtain, a reinforced Concrete Beam is placed at the head of the curtain. To blend in with the protected environment (listed site), a bush-hammered Concrete cladding was used. Cast steel mooring Bollards and elastomer docking fenders will complete the structure. River traffic on the canal will be maintained throughout the works.

Work was interrupted on April 1, 2012 to ensure the tranquillity of the colony of Mediterranean coastal heritage birds for which this area is the main nesting site. Work resumed on July 31, 2012.