Water Transport Solutions

River locks in Trier, DE | 2018

However, the dimensions of the existing locks are no longer up to date and cause waiting times when passing through the locks. In addition, freight transport has to share the route with the abundant tourist excursion boats. Therefore, the locks are now being successively equipped with a second lock chamber, which has standard dimensions of 210 m x 12.5 m.

Download the full case study

The locks at Zeltingen and Fankel have already been expanded and are in operation.

The lock at Trier was one of the first to be completed during the earlier Moselle expansion. Its age and the volume of traffic were the main reasons for the decision to start construction of a second lock chamber. The overall construction project includes the expansion of the upper and lower outer harbor to a length of 225 m, the relocation of the Trier gauge, the construction of a new control center for the Zeltingen, Wintrich, Detzem and Trier lock systems, as well as an ecological compensation measure at the Monaise marina.

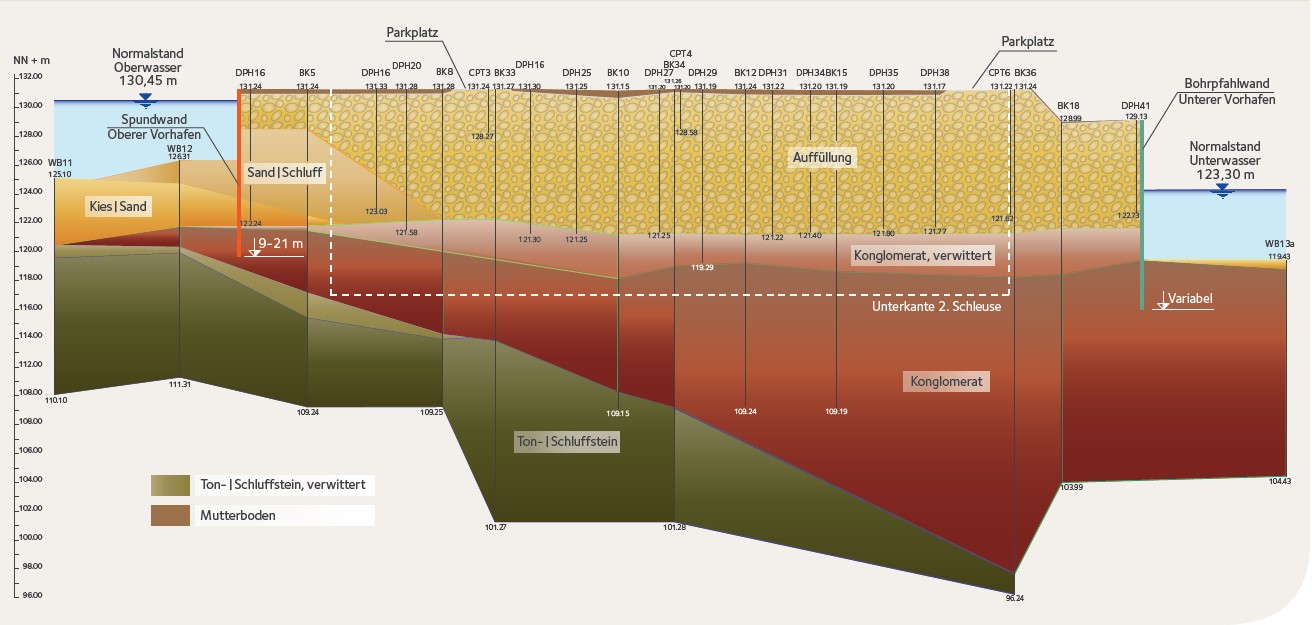

The upper outer harbor, the middle moles in the upper and lower water, as well as various temporary structures, including a dolphin in the lower water, will be built using steel sheet pile walls. The circular cell will be constructed as a circular cell made of AS® 500 sections. The circular cell will be dismantled after the new lock has been built. Due to the geological structure, pre-drilling is required in some areas for the sheet pile wall work. The base of the sheet pile wall must be anchored in conglomerate layers or layers of clay and siltstone of low to medium strength.

A guide scaffold is required to construct the circular cell. Beams are inserted into pre-drilled holes and connected with bent steel elements. The sheet piles are then installed, fixed to the guide and, after the cell has been closed, driving to the final depth can begin. To speed up the work, the planks are partially pulled together into double planks on site. After the construction work is complete, the cell can be dismantled.

The upper outer harbor is constructed with a single-anchored PU 22 sheet pile wall. As a special feature, the sheet piles for the center moles will be factory-fitted with armor plating. A curved plate of the same thickness as the sheet pile wall will be welded to the pressed double pile in such a way that the valley of the wave is closed after ramming and the sheet pile wall is not excessively damaged in the event of a ship collision. The cavity will be filled with sand or other material as planned.

The structure is expected to be completed in 2019. The construction costs are estimated at around 40 million euros.