Water Transport Solutions

Quay wall

8,186 tonnes of sheet piles

South extension of Port of Huelva, SP | 2022

Download the full case study

With the need to cater to growing demands while keeping the Port’s high quality of service, the Port Authority of Huelva decided to welcome the future with the extension of its south quay for increased container handling capacity.

In September 2016 the Port of Huelva awards INCREA the design project. The environmental impact assessment followed with approval in December 2016. The final design and tender specification by INCREA were completed in May 2018. Steel Sheet Piles (SSP) were the solution of choice on the basis of quality assurance and project specific environmental considerations. By May 2019 the project tender had been awarded to Ferrovial as main contractor and was well under way.

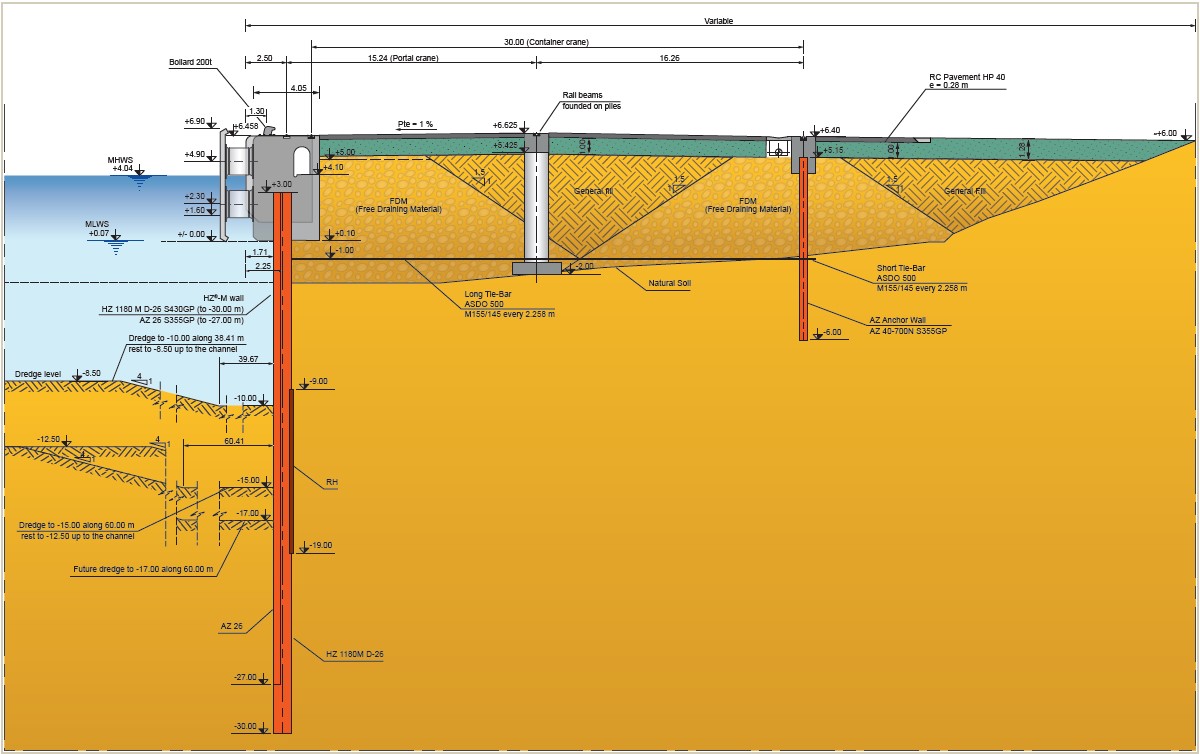

The South Quay extension project consists of a 525 m of quay with a tapered end wall. The quay is designed for 23.5 m maximum retention with mean tidal variation of 4 m.

Due to significant variation in stratigraphy along the wall’s alignment two main design sections and a tapered wing wall were created to optimize the project. The sections follow a typical configuration with a front HZ®-M combi wall tied to a rear anchor wall. Main Section 1 extending 237 m through a zone of soft materials corresponding to a Quaternary fluvial paleochannel bed. Pile toe required penetration in the underlying dense to very dense partially cemented Tertiary silty sands.

This demanded 33 m long double section HZ 1180M D-26 combined with 30 m long AZ 26 intermediary piles and ASDO Ø145/155 tie bars (world’s largest at the time) from Anker Schroeder. The high anchor loads required a custom connection design for adequate transfer into the piles. This design benefited from close collaboration of INCREA and the ArcelorMittal and ASDO engineering design teams.

Main Section 2 extending 287 m is characterized by the presence of a layer of Quaternary gravels and sands underlain by the same Tertiary material of the previous section at a shallower depth. The comparatively better soil characteristics allowed for a lighter system combi wall solution comprised of 29 m long single section HZ 1180M D-14 with 23 m long AZ 28-700 intermediary piles.

Profiles AZ 40-700N & AZ 28-700 are used for anchor-walls in lengths of 11.15 & 9.15 m.

Distance to front varies slightly in the range of 31-32 m with anchors connected at every main HZ®-M pile.

Temporary SSP installed into a temporary berm in front of the main wall enabled dewatering for the backfilling and installation of tie rods 1 m below low tide.

Tecnoterra, a sheet piling contractor, installed the sheet piles. Driving of the main HZ-M piles was done with initial positioning via an MS120 vibro hammer and final drive via an BSP CG240 Hydraulic impact hammer with 16 t drop weight delivering 235 kNm of energy per blow with a blow rate of 26/min. Hard driving conditions in Section 2 were little challenge with the equipment and experience of Tecnoterra, whom managed a speedy installation without employing additional hard driving measures. Intermediary and anchor wall piles were driven with the MS120 and an MS32 vibro hammers respectively.

An innovative hydraulic levelling guide frame was designed and patented by Ferrovial specifically for this project. Installation achieved impressive productivity rates of 7 double HZ-M piles per day and 12 single HZ-M piles per day.

It should be noted that this project has progressed successfully and safely under the shroud of the COVID-19 world pandemic. The inherent installation simplicity of the ArcelorMittal solution and the ASDO anchoring system have been major contributors to making social distancing easily manageable onsite. Moreover, trust and cooperation between the port of Huelva, Ferrovial, and all other stakeholders have been at the root of this victory against the difficulties of the times.

The new quay is expected to start operation first quarter 2022.