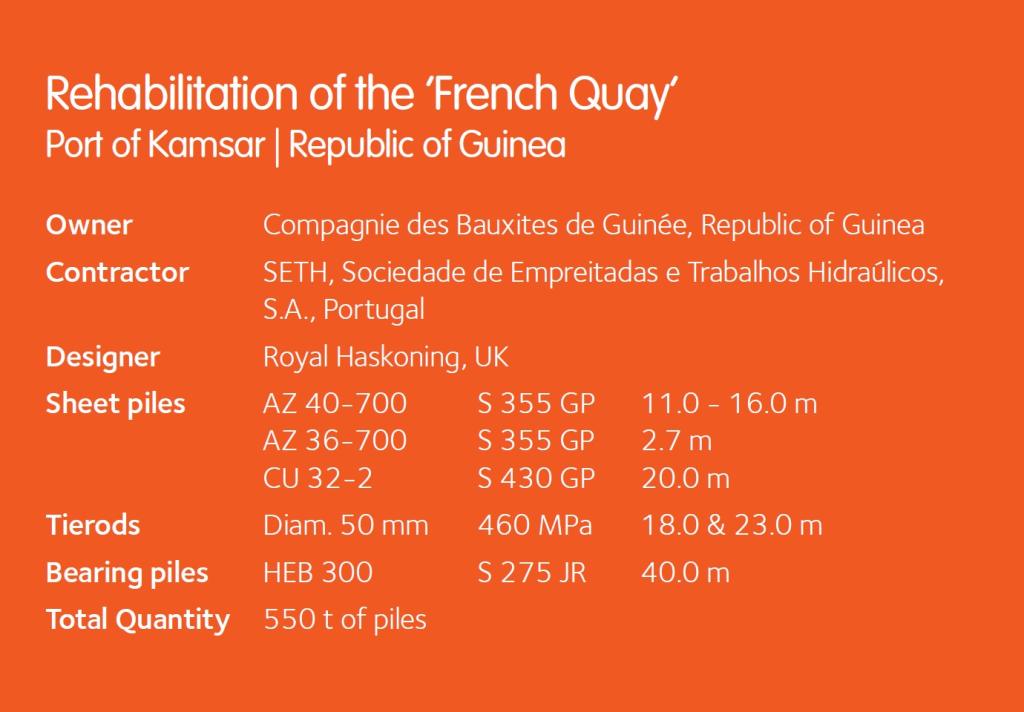

Rehabilitation of Kamsar Port, Guinea | 2007

An important step in the economic development of the Republic of Guinea

The Republic of Guinea possesses one of the world’s largest reserves of bauxite, the raw material used for the production of aluminium. The ‘Compagnie des Bauxites de Guinée’, CBG, is engaged in developing and exploiting the local bauxite reserves located in the North West of Guinea.

The Port of Kamsar has three quays: the 'Mineral Quay' for bauxite export, the 'Italian Quay' for tug boats and small vessels, and the 'French Quay' as the main import facility for mine and township supplies.

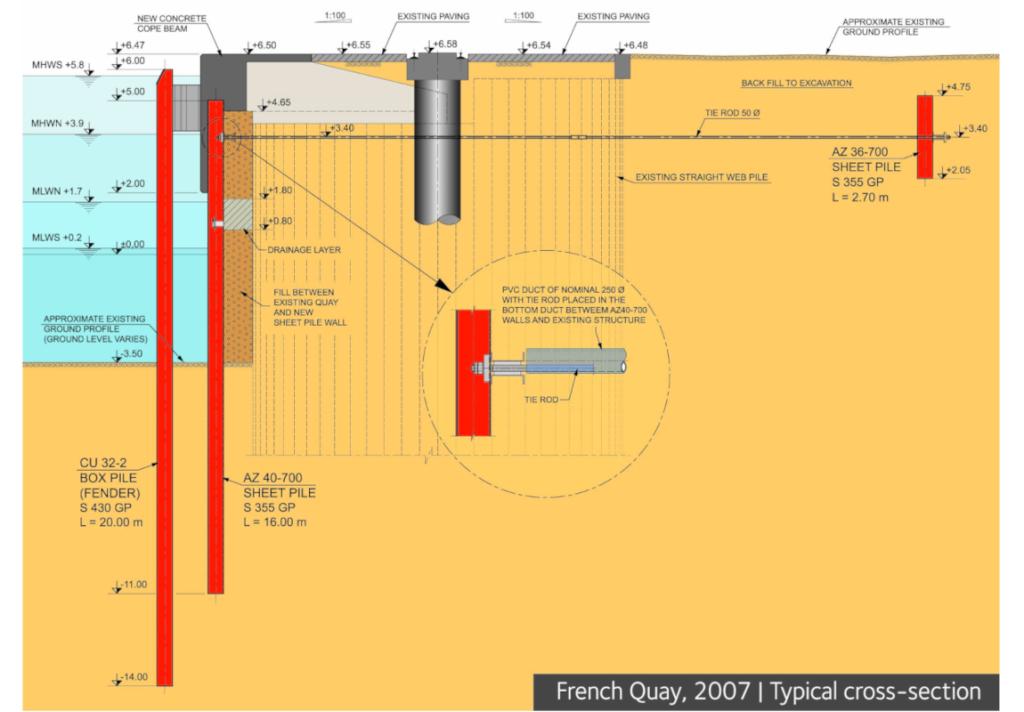

Early in the 21th Century, CBG decided to extend the service life of their facility. As could be expected after such a long period of use, the structure needed to be rehabilitated. The most cost-effective solution that matched all the design criteria and construction constraints was the installation of a new sheet pile wall in front of the existing diaphragm cells.

English

English

French

French