Welding of steel sheet piles

Brochure with details of welding specifications and welding procedures specific to steel sheet piles

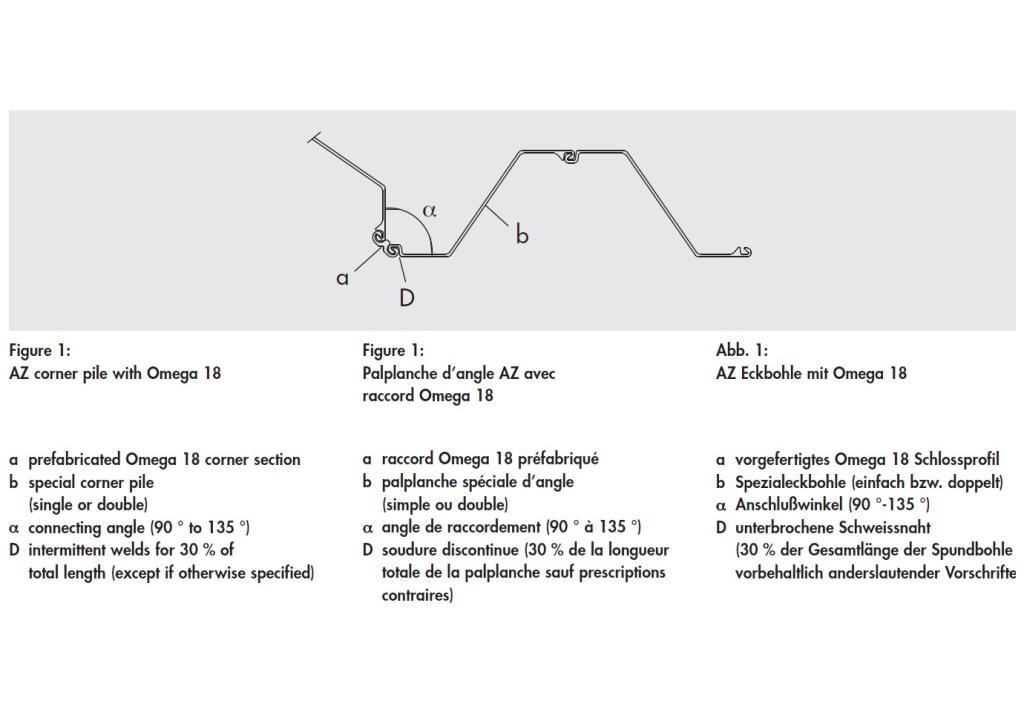

Installation of continuous steel sheet piling and bearing piles may call for site welding and cutting.

This document offers recommendations and guidelines on welding problems encountered when making the more common assemblies, to supplement the information in EN 12063 and EN 12699.

The welding and cutting operations described relate to ProfilARBED hot rolled U and Z sheet piles and HP bearing piles, and standard structural steel fittings.

Procedures for AS 500 straight web junction piles and HZ bearing piles need special approval and are not dealt with herein.

This brochure is available in 3 languages: English, German and French.

Download

English

English