Join us at Bauma 2025

From April 7 to 13, 2025, ArcelorMittal will participate in Bauma 2025, the world's largest event dedicated to construction machinery and materials. This year, we will showcase our innovative and sustainable steel solutions at two stands, covering both foundation solutions and flat steels for the construction industry.

Event highlights

Our Sheet Piling and Wire Solutions divisions will be at Stand 338, Hall C5.

Our Flat Products, Plates and Tubes divisions, as well as Industeel, will be at Stand 518, Hall A6.

Attend the conference on low carbon-emissions solutions on Monday 7 April 2025, 16.30 – 17.00

Conference: ArcelorMittal's journey towards net zero steel

Arne Langner, communications manager for Germany, will speak on Monday 7 April 2025, 16.30 – 17.00 at the Innovation Hall Bauma LAB0, ICM (next to entrance West).

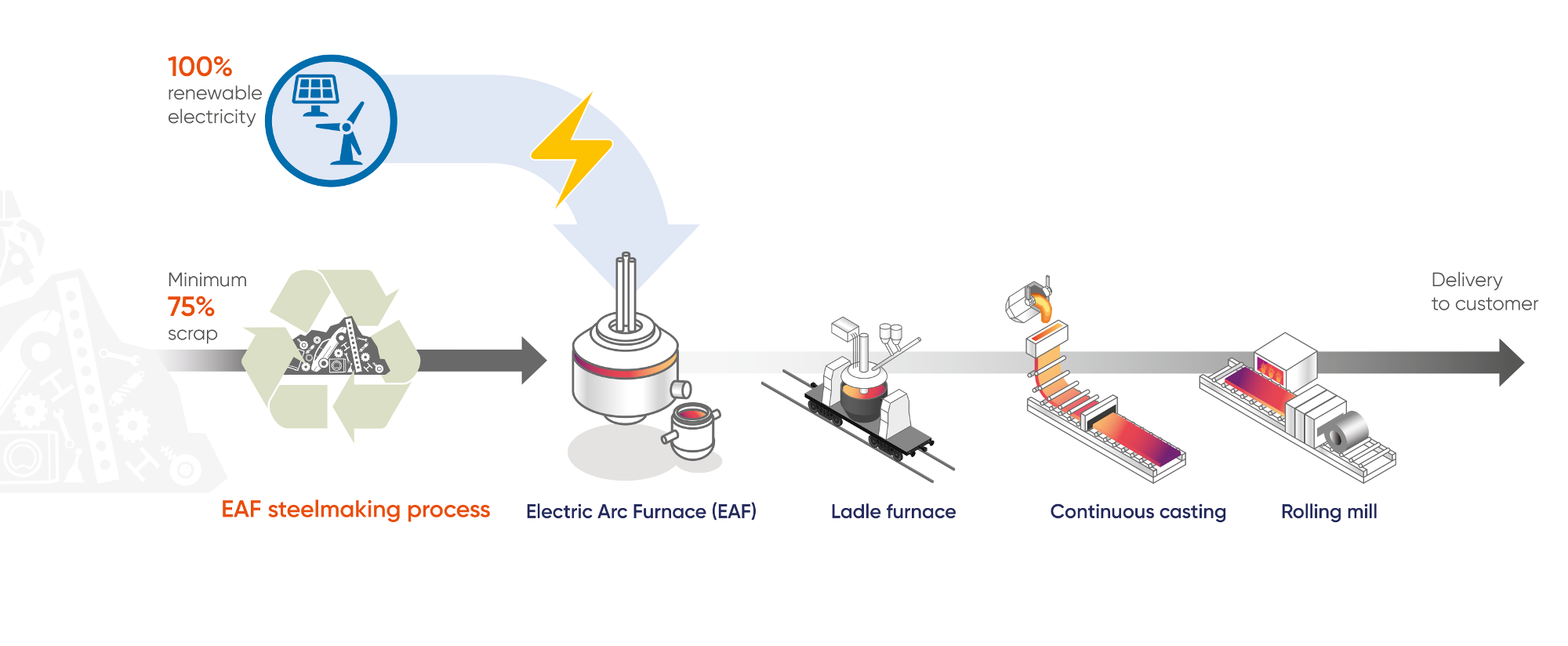

ArcelorMittal is transforming steel production to drastically reduce its carbon footprint, on a journey towards net zero steel. Under the XCarb® brand, significant investments, particularly in Germany, enable us to offer recycled and renewably produced steel products. Made from recycled steel (scrap) and renewable electricity from solar and wind power, they are available as coils, sheets, profiles, tubes, cables, beams and sheet piles, in various steel grades. They achieve up to 81% lower CO2-emissions than traditional products, as confirmed by certified Environmental Product Declarations. Embracing the circular economy, many of these products can be reused multiple times and are fully recyclable when decommissioned.

Sheet Piling and Wiring: Hall C5, Stand 338

ArcelorMittal Sheet Piling will showcase resilient, sustainable and smart steel foundation solutions, addressing climate change adaptation with reinforced flood protection barriers and strengthened coastal erosion barriers using steel sheet piles. ArcelorMittal’s newly released video, "Sheet piles can save lives", will be showcased at our booth. This presentation will serve as an engaging introduction, setting the stage for in-depth discussions with the ArcelorMittal Sheet Piling team of experts.

The results of a comparative study on underground car parks will highlight the benefits of the EcoSheetPile™ Plus range against alternative materials. This study will also highlight the use of low carbon-emissions steel, featured as part of the XCarb® recycled and renewably produced brand. ArcelorMittal Sheet Piling is also driving innovation with the SmartSheetPile solution, an advanced system designed to ensure the long-term safety, enhanced durability and reliability of infrastructure. SmartSheetPile leverages cutting-edge technology, including sensors, data analysis, digital twins and Artificial Intelligence (AI), to create a real-time monitoring and alerting solution. Lastly, we will demonstrate our commitment to sustainable development and the circular economy, focusing on recycled steel products and reuse strategies.

Wire Solutions will exhibit low carbon-emissions hoisting and mining ropes, a full product range for applications from the bottom of the sea to the highest ski lifts in the world, available worldwide. Two unique hoisting samples and two for mining will be displayed on the stand.

Industeel, Flat Products, Plates and Tubes: Hall A6, Stand 518

Amstrong® and Amstrong® Ultra are high strength steels with proven engineering performance. Amstrong® Ultra coils and sheets are available in up to 1100 MPa and in coils and sheets up to 2000 mm wide. Amstrong® is available as XCarb® recycled and renewably produced steel, resulting in a significant reduction in CO2 emissions, approximately 75% lower compared with steel made via the conventional steelmaking route. Structural and high strength plates are available from 235 to 960 MPa, and from 4 to 500 mm thickness.

Relia® is our range of high hardness, low-alloyed martensitic steels, available everywhere in Europe through a network of 50 distributors. Relia® offers 400HBW to 500HBW, in 3 to 150 mm thickness.

Our Tubular Products division will also be in Hall A6, stand 518, showcasing ArcelorMittal’s capabilities in processing and forming steel to deliver the highest quality steel tube solutions. Visitors will have the opportunity to explore our comprehensive range of tubular products for construction and engineering, including structural hollow sections and precision tubes. These products can be manufactured using high-strength materials to perform in highly demanding applications tailored to the specific needs of each customer.

XCarb®, towards net zero steel

Both stands will present XCarb®, ArcelorMittal's towards net zero steel transformation programme. XCarb® brings together all the company's reduced, low and zero-carbon steel products, processes, technologies, innovation projects, initiatives and alliances in one single-minded effort to make the changes needed to get our organisation and industry to net-zero by 2050. It is fundamental to ArcelorMittal becoming the steel company of the future.

As part of the initiative, ArcelorMittal’s XCarb® recycled and renewably produced label is applied to steels produced in an electric arc furnace (EAF) using high levels of scrap and 100-percent renewable electricity.

All the products presented at Bauma 2025 are available in XCarb® recycled and renewably produced, offering as much as 81% less CO2 footprint compared with the same products made via the conventional blast furnace route.

Our specialists will be glad to discuss and advise you on the best solutions for your projects.

Contact your ArcelorMittal representative to ask for a tradeshow voucher.

Registration and information

See you in Munich from April 7 to 13, 2025, at Halls C5.338 and A6.518 !