Rochester Riverside Regeneration, UK | 2009

A transformative regeneration project in Kent, UK

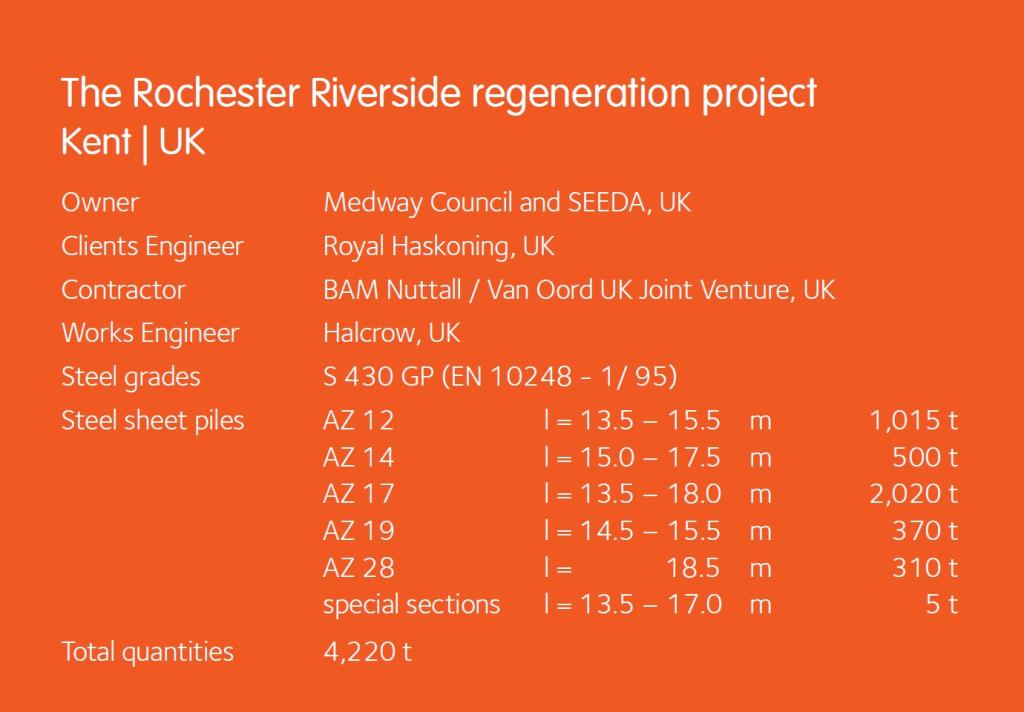

Owned by Medway Council and its partner, South East England Development Agency (SEEDA), Rochester Riverside is a part of the Government’s Thames Gateway growth area, one of Europe’s largest regeneration schemes.

The Medway area is located in Kent and includes the towns of Rochester, Gillingham, Rainham, Chatham and Strood. Medway has experienced sustained growth and diversification during the last two decades.

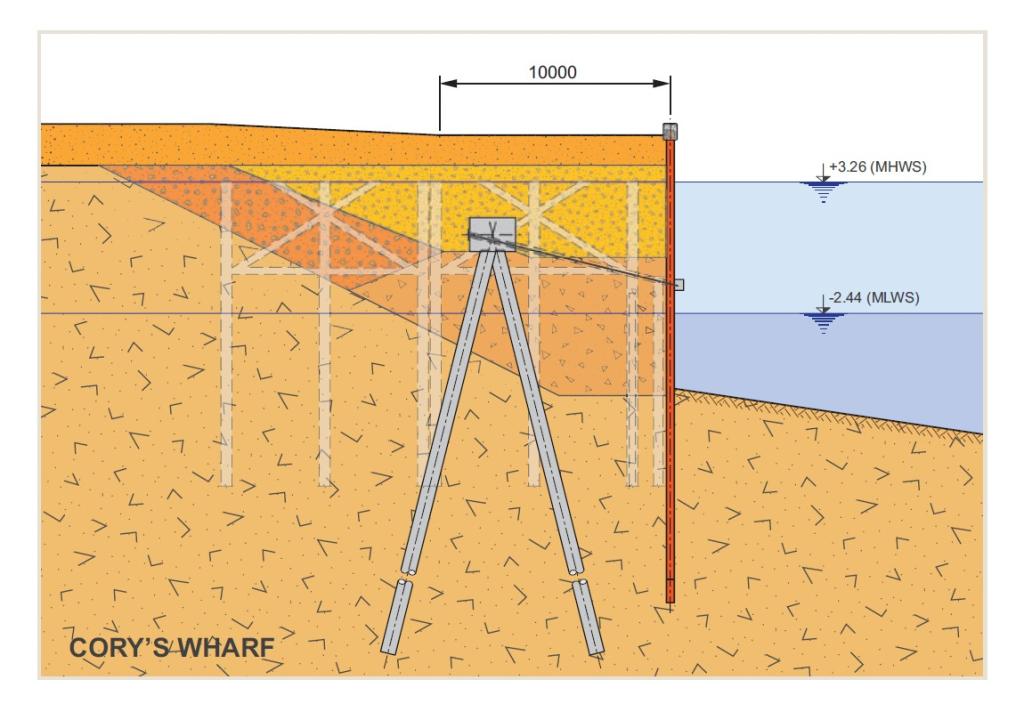

Rochester Riverside is a flagship project within the Medway Council regeneration programme. It is a 32 hectare brownfield site with a 2.5 km frontage along the River Medway selected for the development of a mixed use complex including up to 2,000 new homes, shops, hotels and cafes, offices, educational, health and community facilities and recreational areas.

English

English

French

French