Water Transport Solutions

Multimodal platform, Port of Thionville-Illange, FR | 2014

Download the full case study

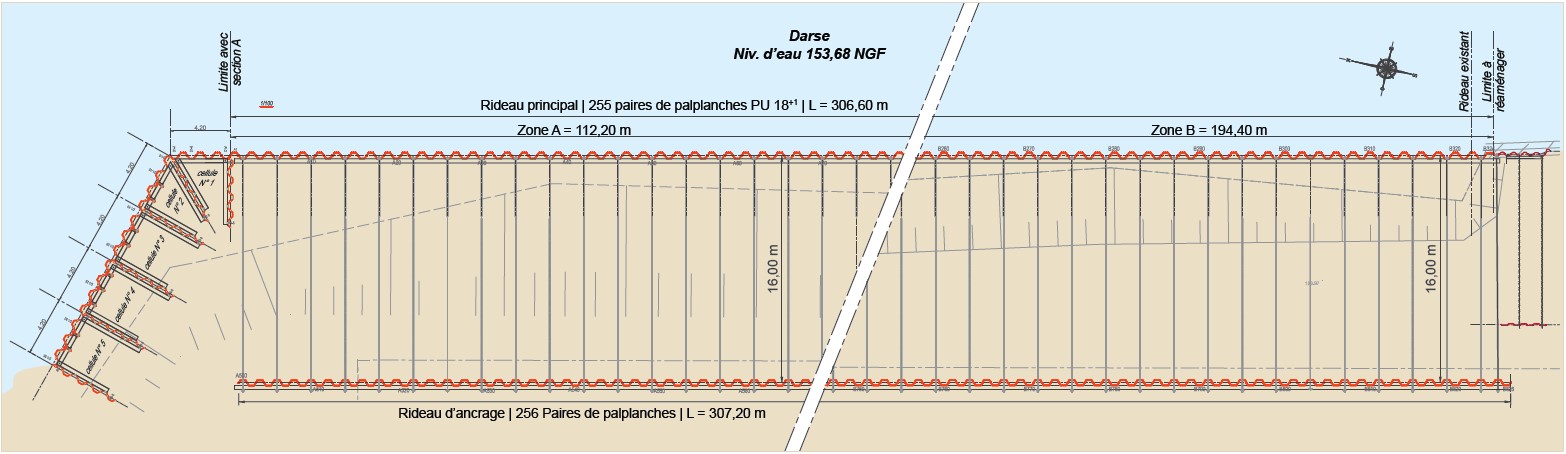

The modernisation of the existing port site involved building a 10-hectare container terminal with a 306-metre-long quay able to accommodate pushed barges with gauges ranging from 90 m to 180 m in length and 10 to 11.4 m in width for a maximum tonnage of 4,400 tonnes.

The construction of the new quay in the extension of the existing quay required 4 months of work without disrupting the activity of the port area, a constraint defined by the project owner. The new structure is being built in several phases: installation of the main sheet pile wall, followed by that of the anchor wall and finally the installation of the tie rods and anchors.

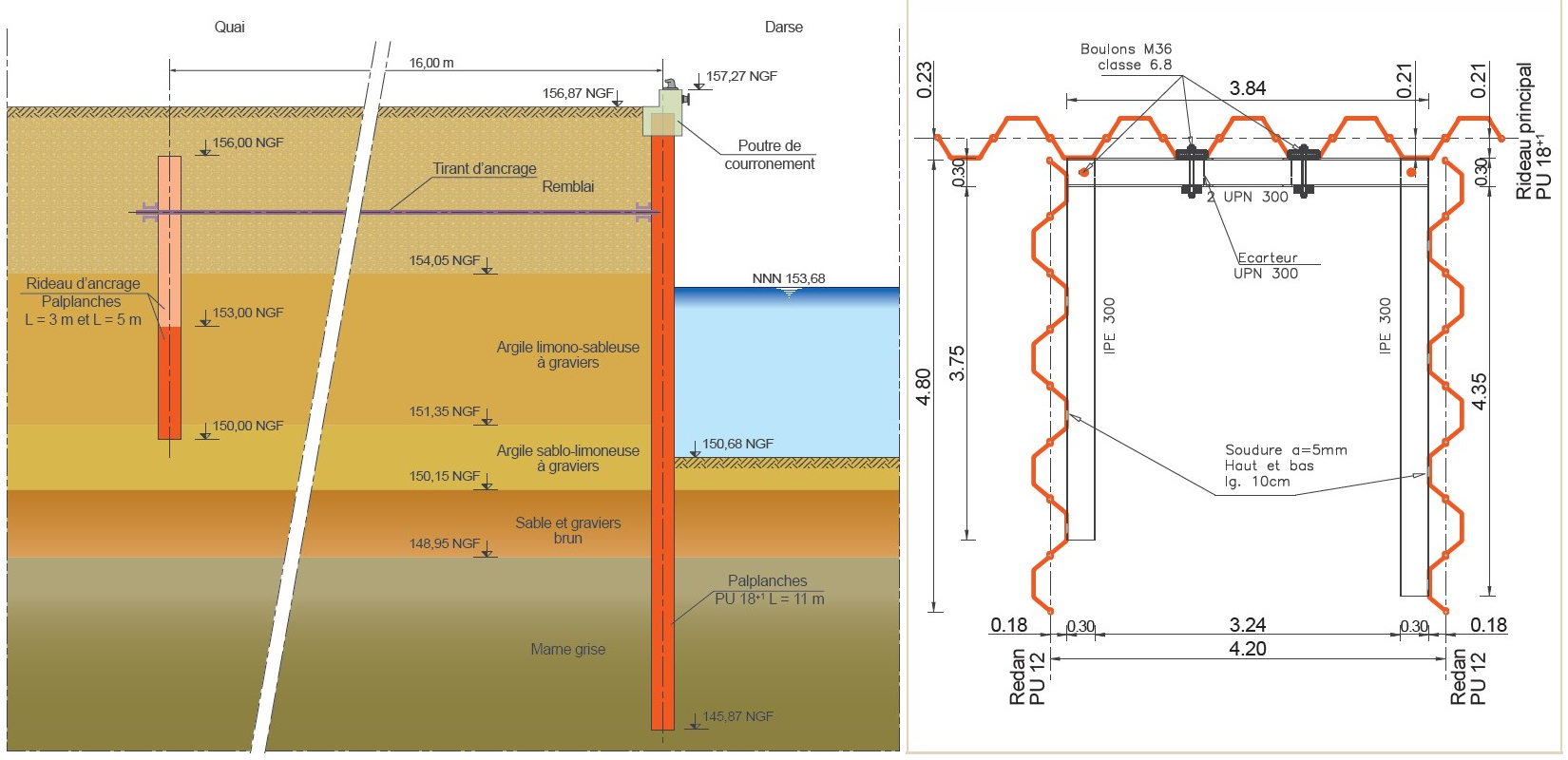

The 11 m long PU 18+1 sheet piles used for the main wall were driven using an ‘ICE 416L’ hydraulic vibrator, then anchored at the foot in the 3 m thick marl using a ‘Delmag D19-52’ diesel hammer.

In the reduced-gauge zone, due to the presence of a high-voltage overhead power line, the pile-driving workshop used an ‘ICE 28RF’ variable-frequency hydraulic vibrator mounted on a telescopic crane to limit vibrations in the vicinity of the EDF pylons.

The anchoring wall was executed in ‘trouser-leg’ fashion, i.e. alternating 3 and 5 m paplanches.

In the reduced-gauge zone, GTS opted for a 40 m-long stepped wall as an alternative to the anchor wall. The anchor bolts were replaced by several walls of PU 12 sheet piles, each 7 m long and set at right angles to the main wall, forming 5 open cells. The sheet piles were installed using a ‘Movax SPH80’ vibrator mounted on an excavator.

To ensure the stability of the structure, 612 m of tie rods and 129 passive tie rods 16 m long and 2.4 m apart were also installed. After backfilling to an elevation of -0.4 m below the final elevation and recutting the main wall, the reinforced concrete crown beams (L= 65 cm x H= 50 cm) were built. 10 steel mooring bollards protected by an ACQPA anti-corrosion coating, 78 elastomer berthing fenders and ladders completed the structure.

Work began in September 2014 and was completed at the end of 2015.