Environmental Protection Solutions

Randweg A2, Eindhoven, NL | 2007

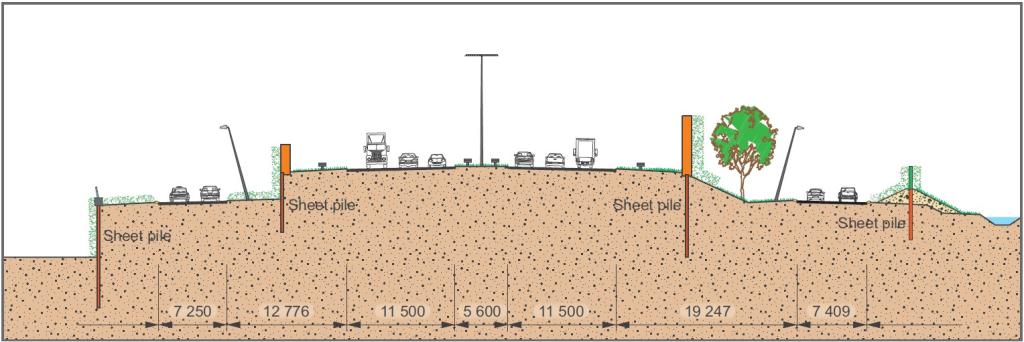

The Eindhoven area is very densely populated. A key part of the project therefore consisted in constructing around 16 km of efficient noise barriers in order to reduce the nuisance of the increased traffic on the vicinity. The landscape was quite unfavourable for such a widening of the highway, as on some sections significant level differences occur between the highway and the local area. The easiest way to overcome these level differences without loss of space was the use of sheet piling retaining walls.

Download the full case study

In addition, the sheet piles showed even more advantages. The architects quickly recognised that the corroded surface of steel sheet piles would form a perfect anti graffiti surface. Hence the idea to use them as well as noise barriers naturally arose. In the end, the sheet piles are everywhere, visible or buried in the ground: as retaining walls, as noise barriers, as foundations for transparent glass noise barriers along the bridges and as foundations for the more high-tech noise barriers separating the transit lanes from the local traffic highway.

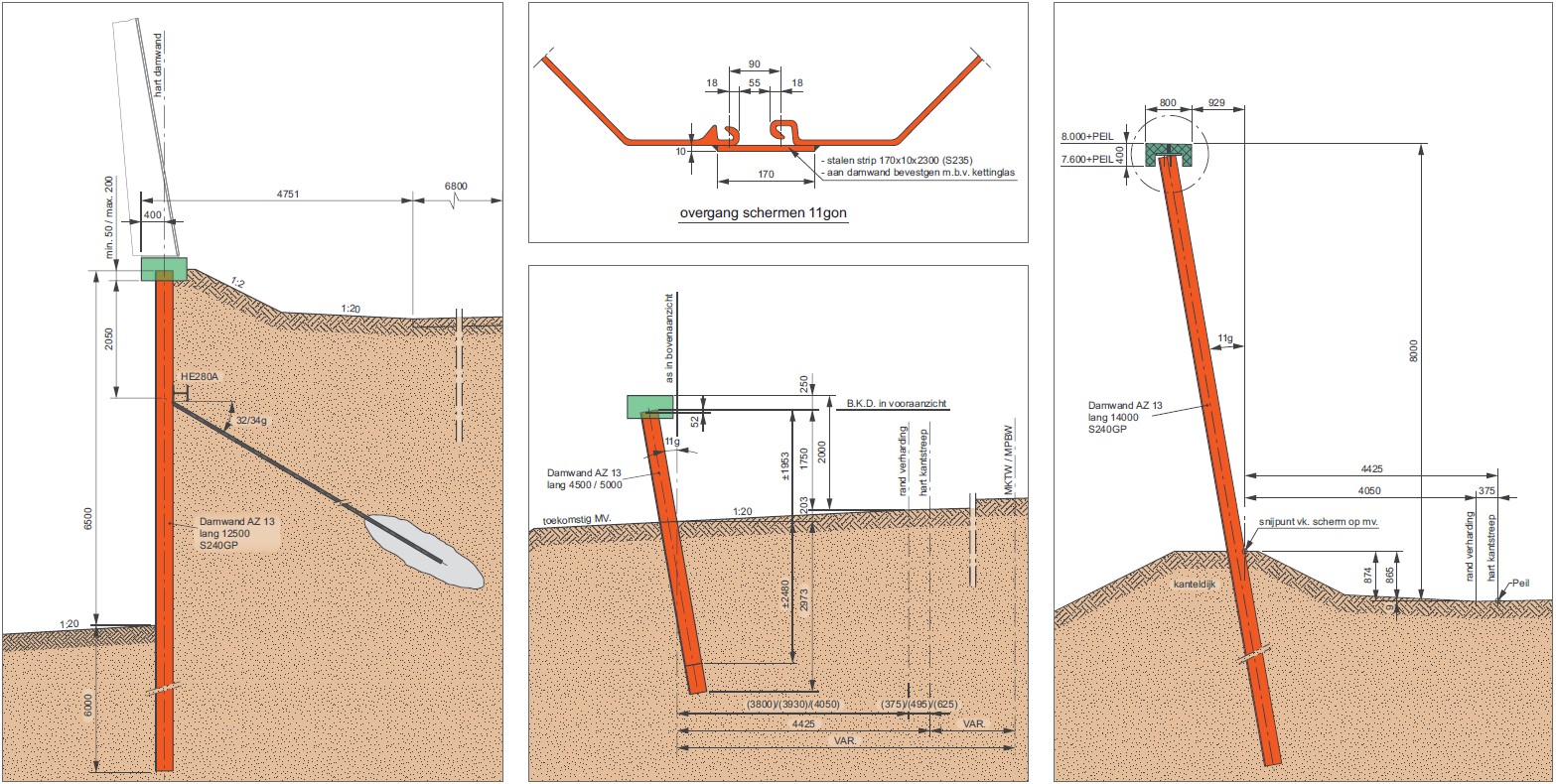

In order to optimise the noise reduction the sheet piles needed to be installed with a small batter angle, resulting in an interesting challenge for the driving contractor. The driving at an angle was easily solved by using a small wooden template that assured the correct angle, but the sheet piles could not follow the curvature of the road without some corrective measures. The difference in linear meter of the wall between the top and the bottom of the bended wall would have created too much lean. This was finally compensated by welding tapered plates in-between every set of three to four pairs of sheet piles, depending on the radius of the bend.

A similar solution was used to work around another unexpected issue. At design stage it was assumed that the thermal dilatation could be balanced out by some play in the interlocks. But on the first warm period after the installation of these very long noise barriers the sheet piles seemed to deform more than predicted. Dilatation joints were executed at regular intervals to balance the temperature fluctuations. The sheet piles were simply cut vertically and a plate was welded at their back on one side, allowing the wall to deform longitudinally.

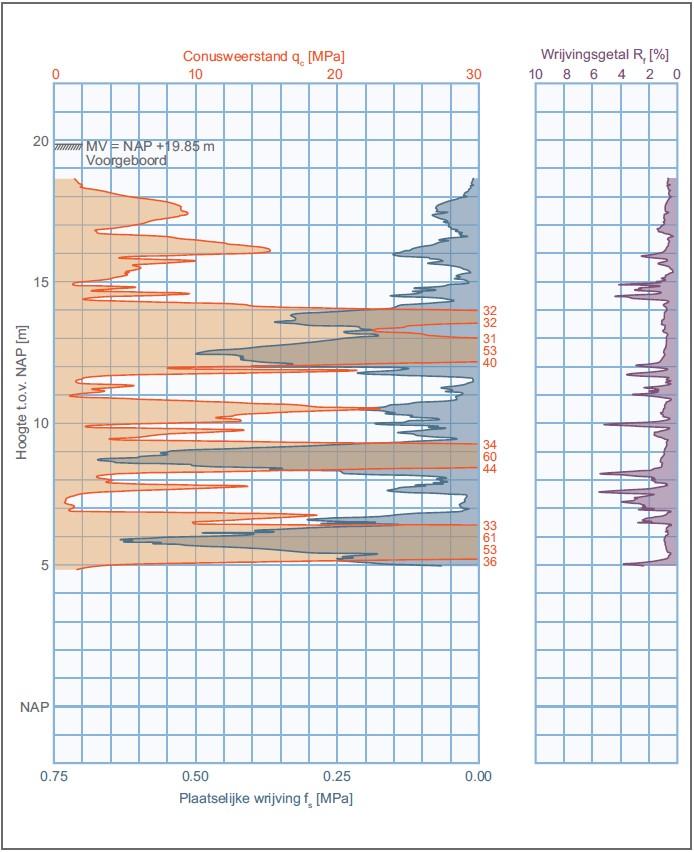

The installation of the piles proceeded with the road works. The soil layers consist of loose to medium dense sand. Mainly AZ 13 sheet piles were used, with lengths ranging from 2 m to 14 m. They were driven with a light vibratory hammer ICE 7RF. The positioning of the prefabricated capping beam required precise driving work but further accelerated the completion of the wall.

From April 2007 to July 2010, some 14 600 t of steel sheet piles were installed for roughly 10 km noise barrier wall which helped transforming tomorrow for all the people living in and around Eindhoven.