Water Transport Solutions

Maritime ports

3,924 tonnes of sheet piles

Unitterminal, Port of Køge, DK | 2018

Port of Køge, one of the largest ports in Denmark in terms of goods turnover, is located less than 50 km south of Copenhagen. The highway E47/E55 and rail tracks connection directly to the port area makes the location an excellent hub for further transportation.

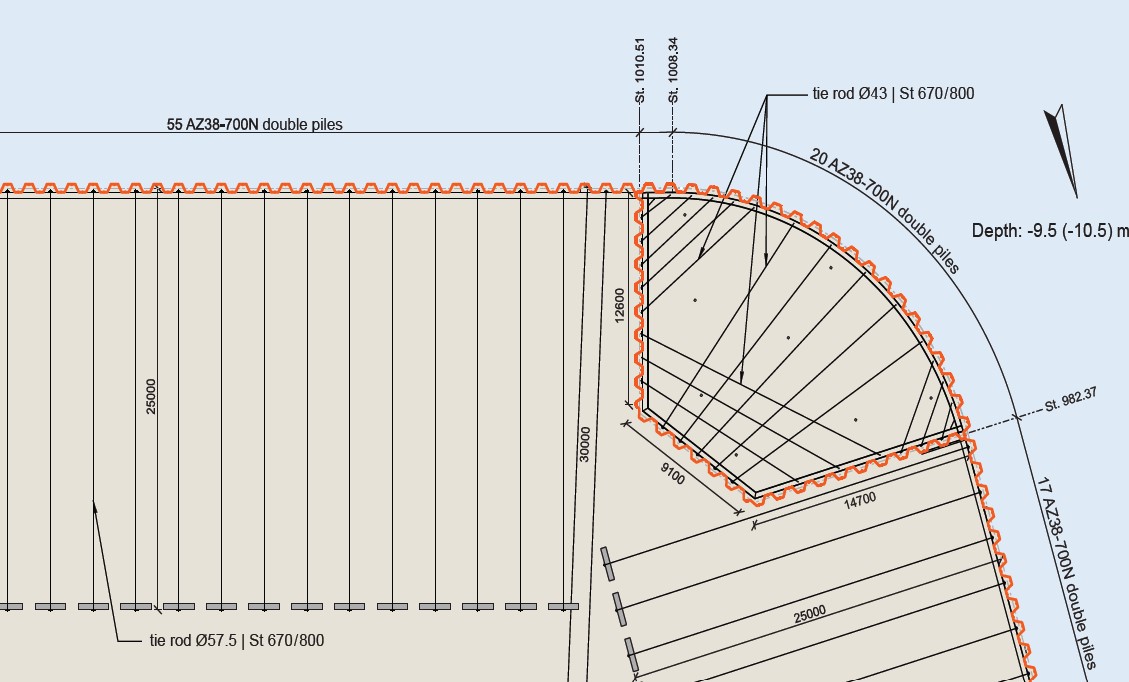

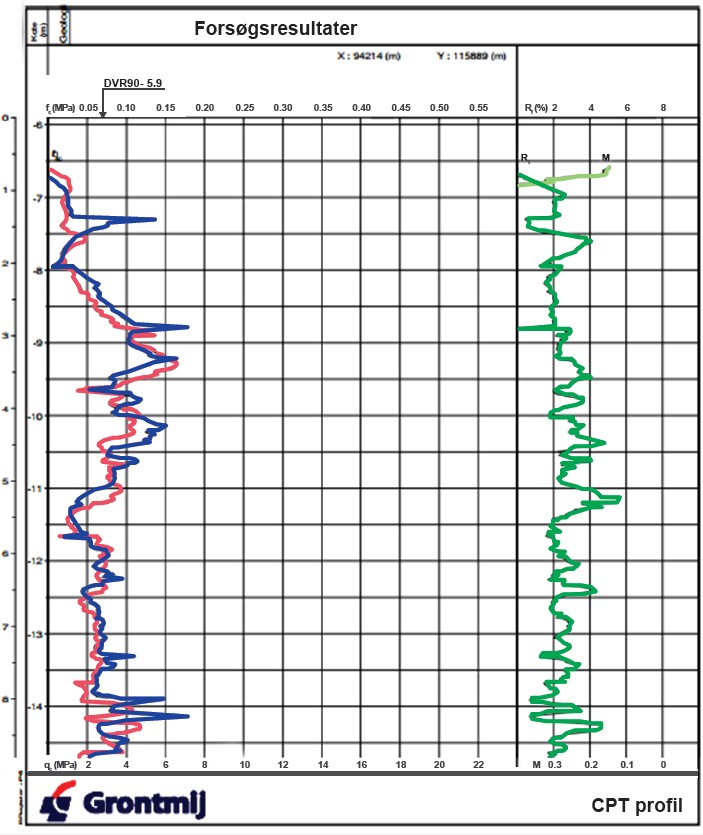

Danish contractor Per Aarsleff A/S started working in 2007 in a partnership with Køge Jorddepot (Soil Depot), Port of Køge, the Municipality of Køge and the Danish engineering company Sweco (previously Carl Bro, and Grontmij). These four actors collaborated to develop a concept for the new port infrastructure, including a new Unitterminal. The expansion plans were to double the size of the port until 2017 by adding around 2 300 m of new berthing facilities.

Download the full case study

The new Unitterminal will be able to service container vessels up to 231 m long and 32.2 m wide, as well as ro-ro vessels. The area is located opposite Køge Jorddepot which was launched back in 2007/2008. The Jorddepot is intended mainly for soil deposits of both clean and slightly polluted soil. ArcelorMittal already supplied in 2007 approximately 4 900 t (an investment of DKK 120 mio, approx. € 16.1 mio) for this impressive project.

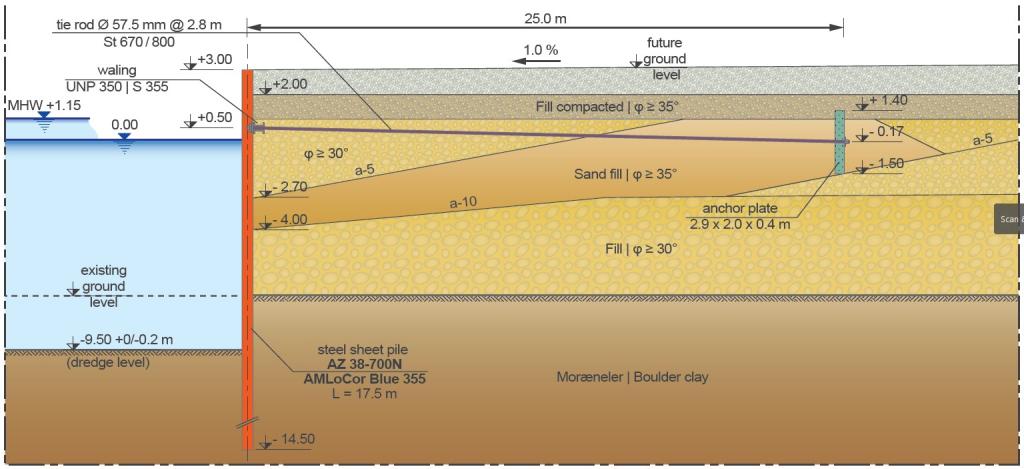

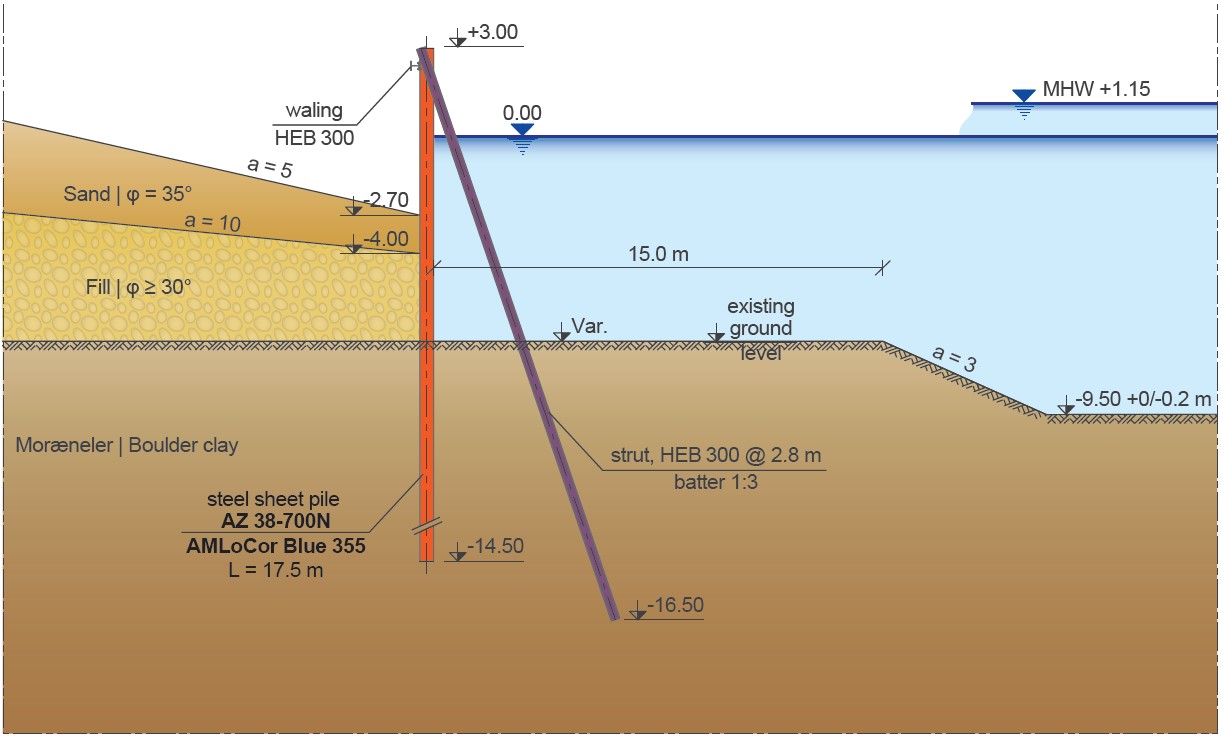

The actual project involved the installation of around 1 200 running meters of steel sheet piles, in lengths ranging from 16.5 m up to 22.0 m, for a total of more than 3 900 t. Three different profiles were supplied in AMLoCor steel grade: AZ 26-700, AZ 38-700N and AZ 42-700N.

The existing water depth in the old Port of Køge is 7.0 m, but the new quay at the Jorddepot and the new Unitterminal has a water depth of 8.5 m and 9.5 m, even though the design of the new Unitterminal considered a water depth up to 10.5 m. The water depth in Køge Bugt and in the new dredged navigation channel in Køge Port will be 9.5 m.

The sheet piles are supported during the first construction phase by battered H-beams, fixed to the sheet piles a few meters below the top. In a second phase, the contractor will backfill behind the sheet pile wall to elevation +2.0 m and later a new pavement up to level +3.0 m will be installed.

ArcelorMittal manufactured and supplied about 260 t of anchor material, including tie-rods, anchor plates, turnbuckles and spherical nuts, to connect the main sheet pile wall to the anchor wall.

Driving of the steel sheet piles took place during the period of December 2015 to August 2016, and was executed by the company Per Aarsleff A/S. The contractor installed the sheet piles with an impact hammer with an energy of 35 kNm (IHC S 70), working from a platform above water.

It is the first major project in Denmark where ArcelorMittal supplied steel sheet piles in AMLoCor, the more corrosion resistant steel grade. From the design and installation point of view, the mechanical properties of AMLoCor sheet piles do not differ significantly from normal carbon steel grades used in construction, but special care towards welding procedures needed to be implemented. AMLoCor has the noteworthy advantage that the corrosion rate for the part below seawater level is 3 to 5 times smaller than corrosion rates observed on normal carbon steel. Above MWL (Mean Water Level) the corrosion rate is similar to normal carbon steel.

Compared to normal steel grades, AMLoCor is slightly more expensive at purchase but, since it requires no or less cathodic protection during a fifty-year lifetime or more, the overall total cost of the structure over its whole service life will apparently be lower than alternative solutions.

The backfilling behind the sheet pile wall up to the level +2.0 m shall be completed by April 2018, and pavement up to +3.0 m will follow shortly after.

The port expansion is expected to be finished and full scale operational in 2022.