Engineering Support

Comprehensive engineering support for steel sheet piling and bearing piles

The technical department offers comprehensive services throughout the world, providing support to all parties involved in the design, specification and installation of steel sheet piling and bearing piles, such as consulting engineers, architects, public authorities, contractors, academics and students.

More than twenty engineers and drafters in our headquarter daily work out preliminary designs (including anchoring systems and lifetime calculations, or fire safety analysis), detailed material lists, pile driving drawings (including special piles for corners or connections), project specific method statements for driving.

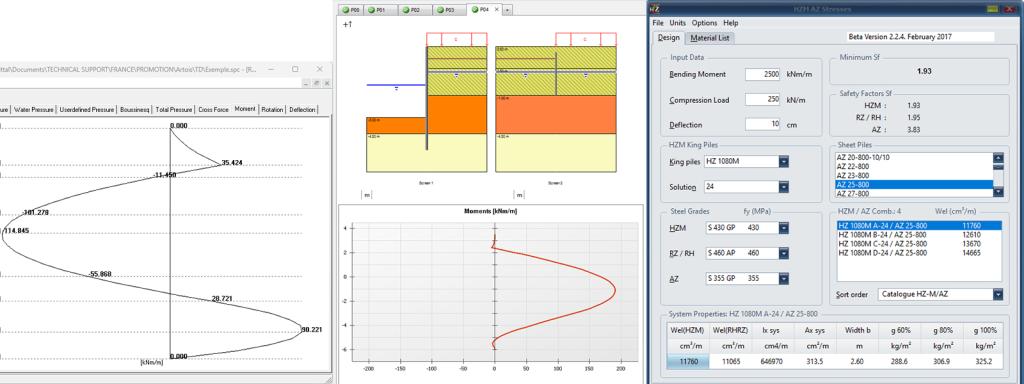

Cutting-Edge Software and Drafting Tools for Comprehensive Sheet Piling Design

The design engineers specialized in the use of sophisticated design software such as Rido, AMRetain, Plaxis, GGU,... as well as our free software Prosheet, Durability, VLoad,...

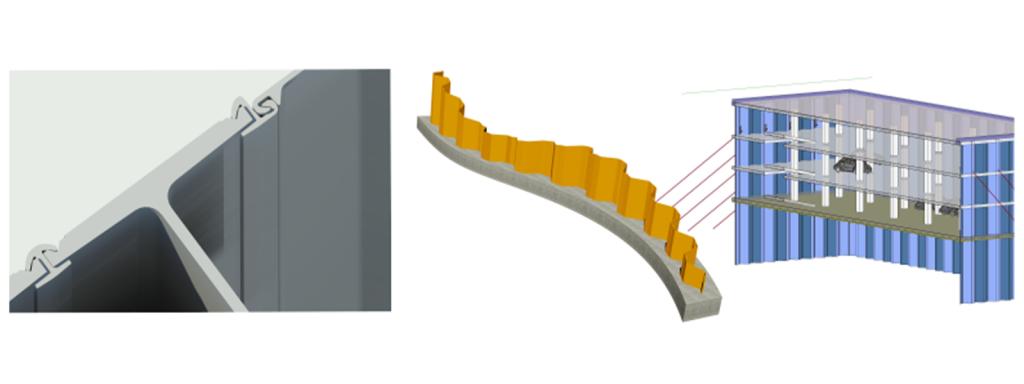

The drafters use CAD software and started now also using Autodesk's Revit software for layout drawings. Additionally, we provide AutoCad files and Revit families of our hot rolled steel sheet piles, including the HZ-M/AZ combined wall system. You can download these files on our website (see links below).

Engineering

Technical Aspects, Design Software, SmartSheetPiles, and Steel Sheet Pile Design

Optimizing Sheet Piling Solutions: Technical Support and Environmental Expertise

The objective of the technical team is to propose the most competitive piling package, and assist the contractor with drawings, installation at the job-site if deemed necessary (mainly for complex structures such as circular cells,...).

Recently, environmental criteria have become increasingly important in the choice of the optimal solution. Our environmental experts can carry out a life cycle analysis (LCA) of a structure based on environmental product declarations (EPD).

Do not hesitate to contact us, our services are free.