Cold formed steel sheet piles

Efficient Solutions in Cold Formed Steel Sheet Piles

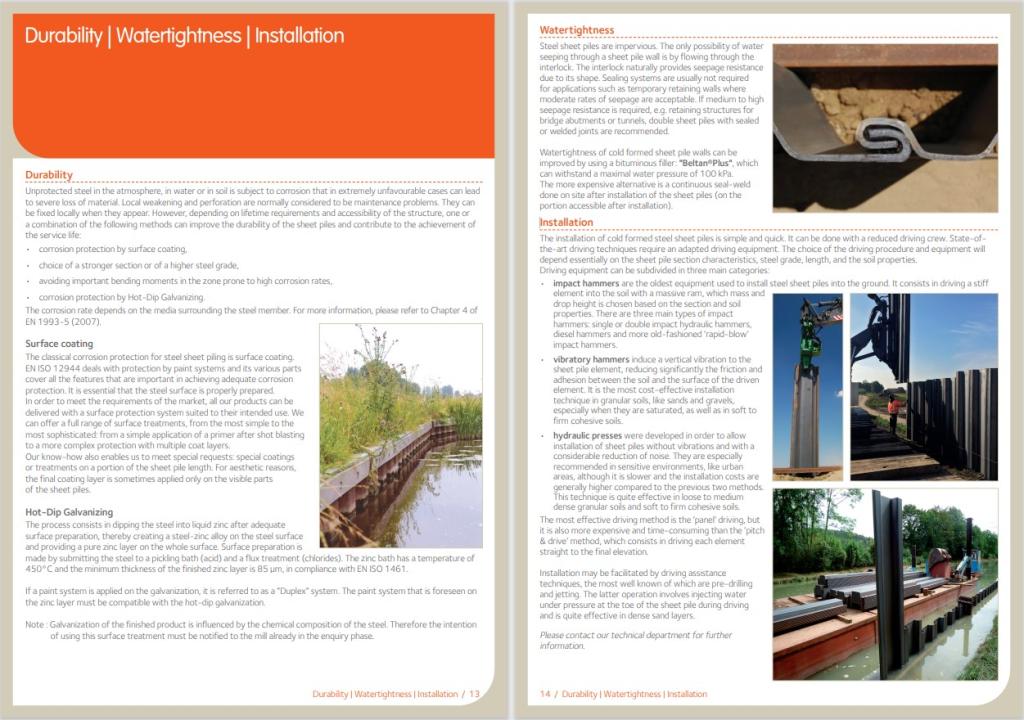

Cold formed steel sheet piles have been used for decades in permanent and temporary structures, like waterfront structures, dykes, river embankments and cofferdams.

Main applications are small retaining walls, temporary cofferdams requesting low watertightness, anchor walls of quay walls, reinforcement of dykes, river embankments, etc.

The installation is quite simple and fast, and can be performed with standard driving methods, with a reduced driving team as well as usual driving equipment like impact hammers, vibratory hammers or hydraulic presses.

English

English

German

German

French

French

Dutch

Dutch